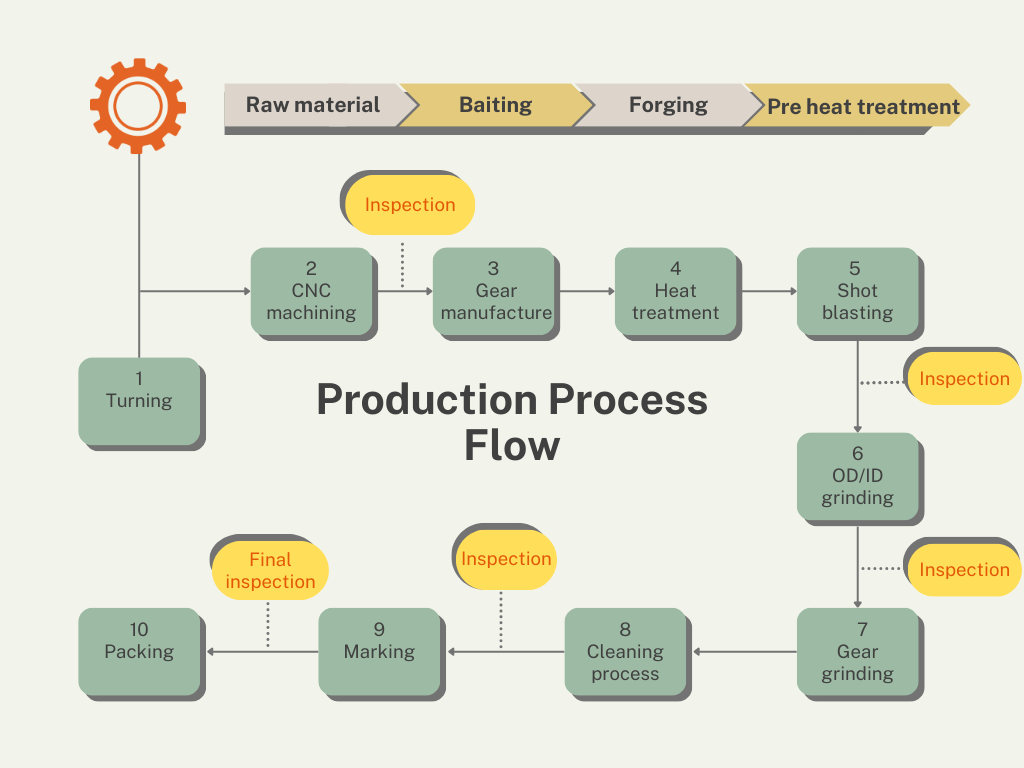

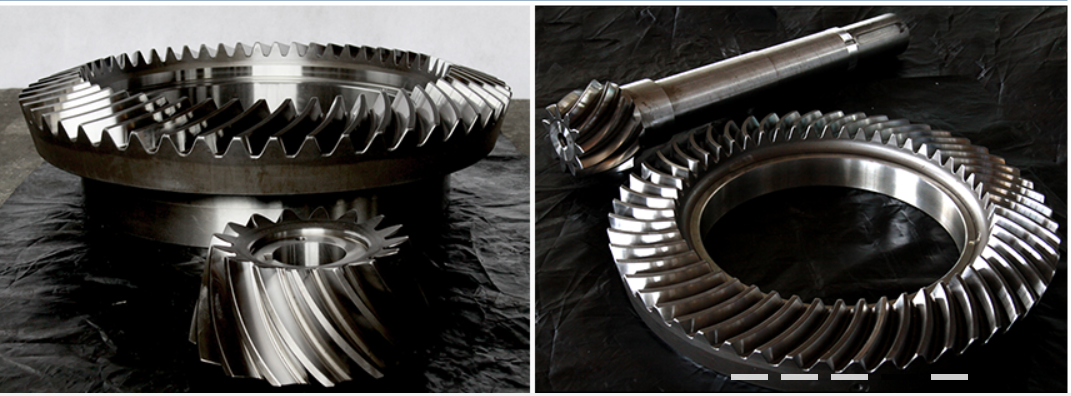

Our 5-Axis Gear Machining service is versatile and suitable for various industries, including automotive, aerospace, and industrial machinery, where precision, strength, and reliability are paramount. When you choose our service, you're investing in gears of unparalleled quality, custom-tailored to your exact specifications.

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1) Bubble drawing

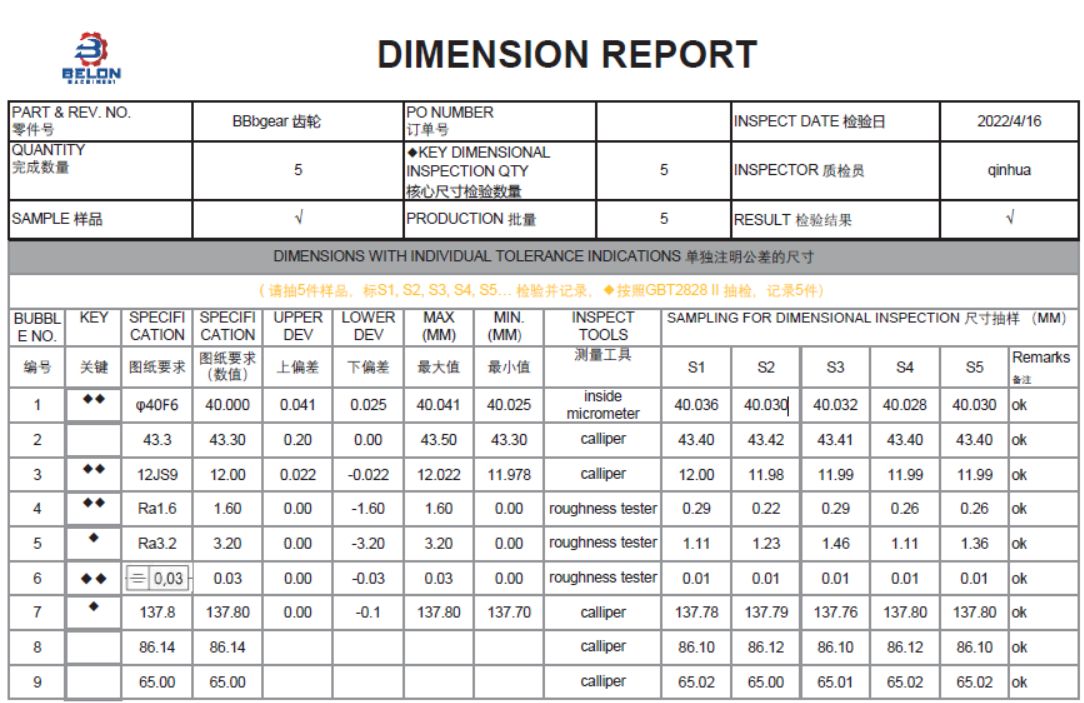

2) Dimension report

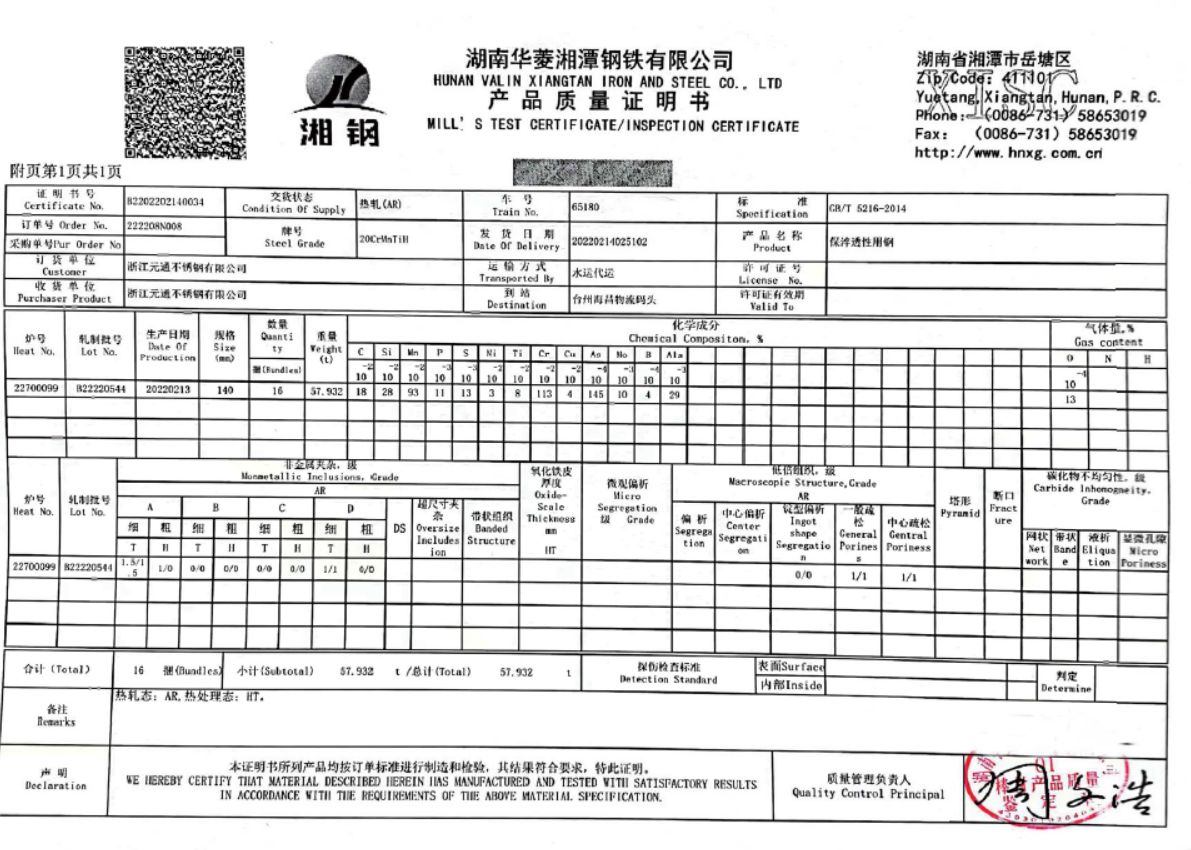

3) Material cert

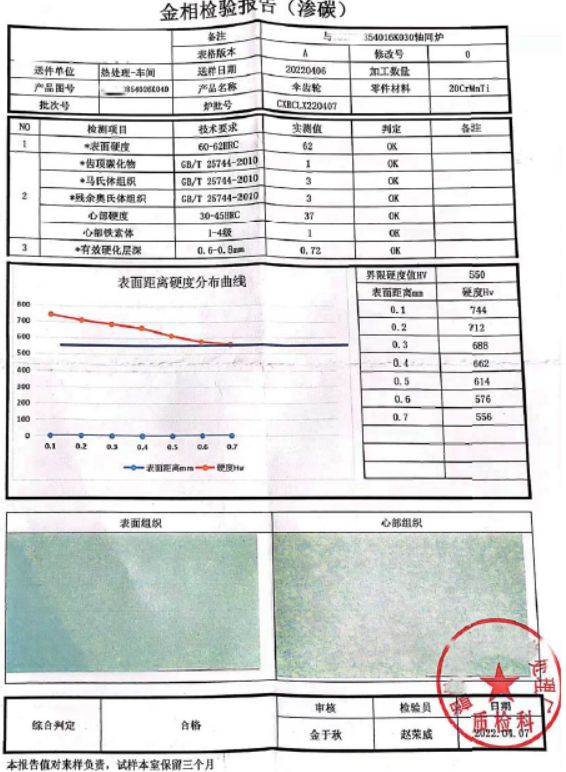

4) Heat treat report

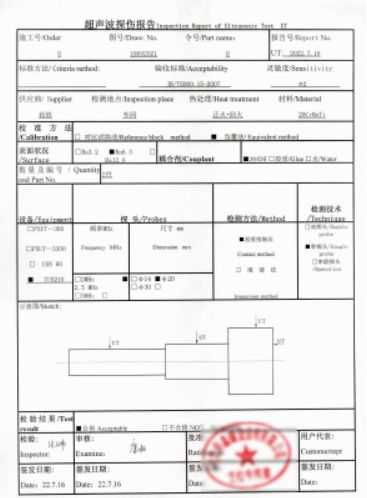

5) Ultrasonic Test report (UT)

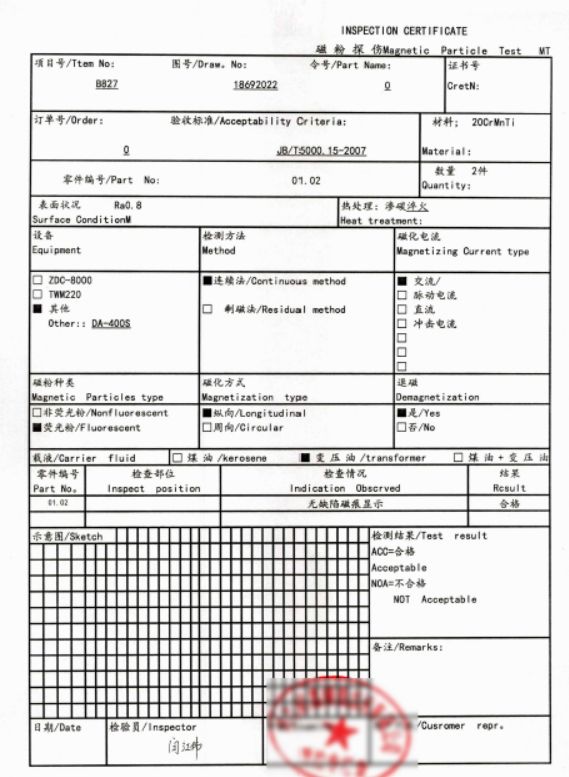

6) Magnetic Particle Test report (MT)

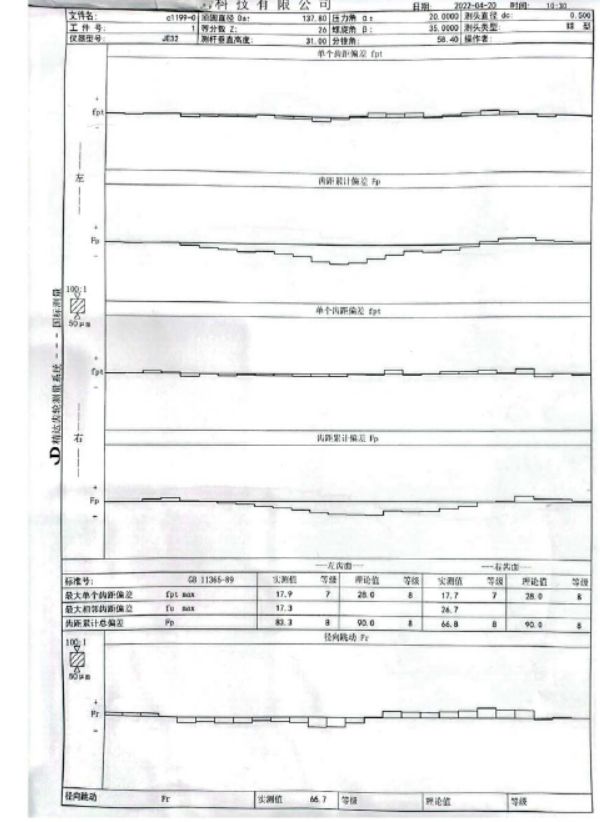

Meshing test report

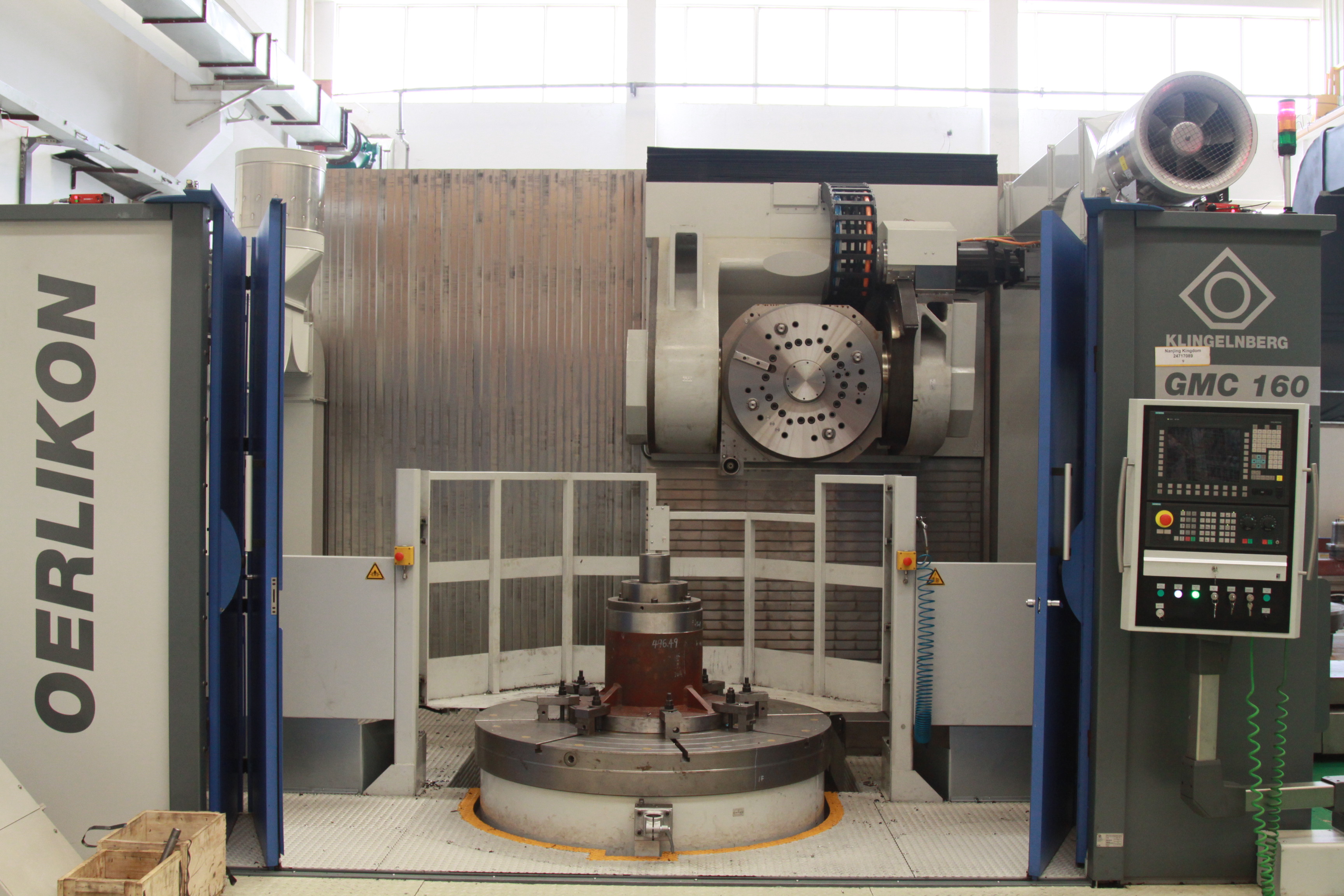

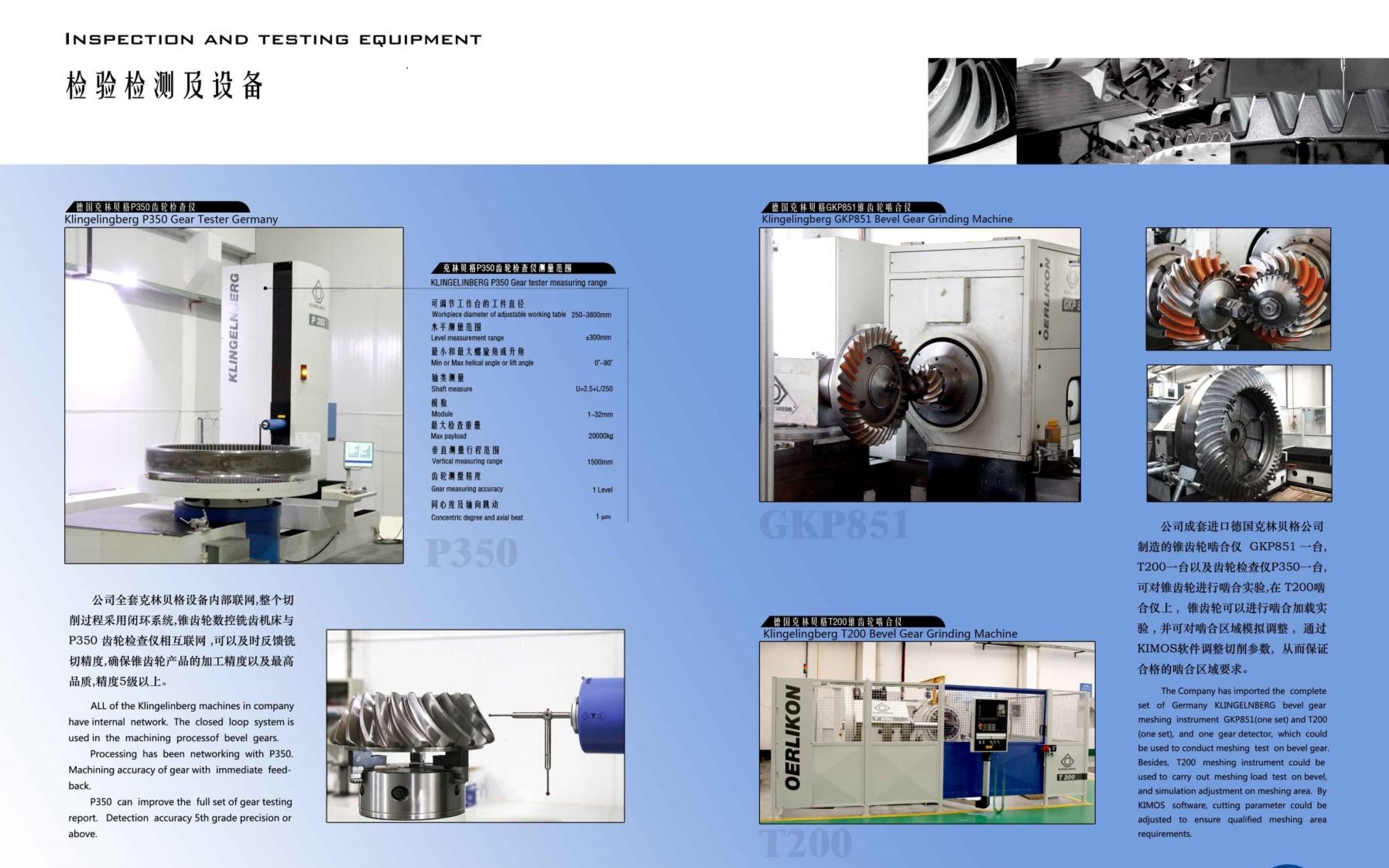

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.