High Strength Straight Bevel Gears are an excellent choice if you are looking for reliable and accurate 90 degree transmission. Made of high-quality 45# steel, these gears are durable and designed to provide maximum power transmission efficiency and accuracy.

For industrial applications requiring precise and reliable 90-degree transmission, high strength straight bevel gears are the ideal solution. These gears are precisely engineered to ensure peak performance and ensure smooth and efficient operation.

Whether you're building machinery or working on industrial equipment, these bevel gears are perfect. They are easy to install and operate, and can withstand even the harshest industrial environments.

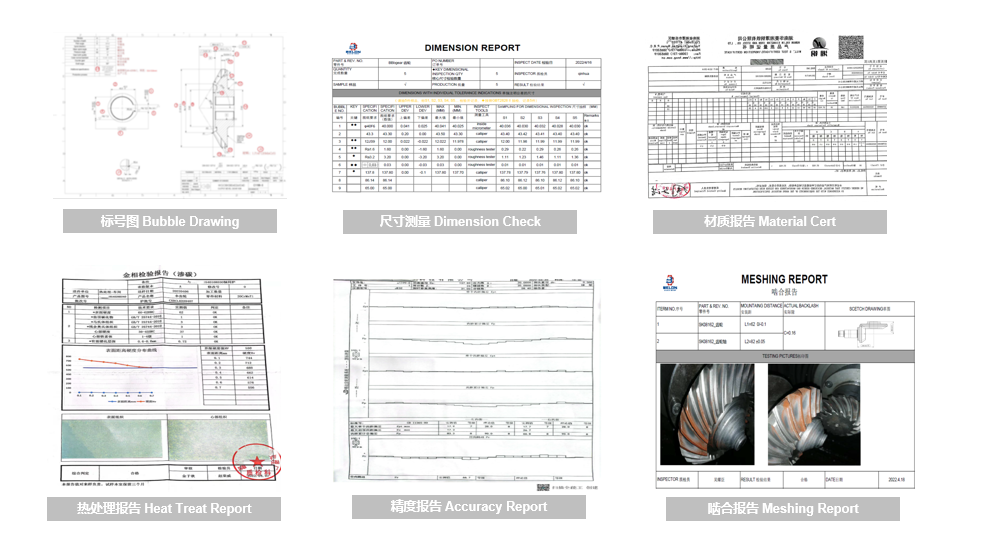

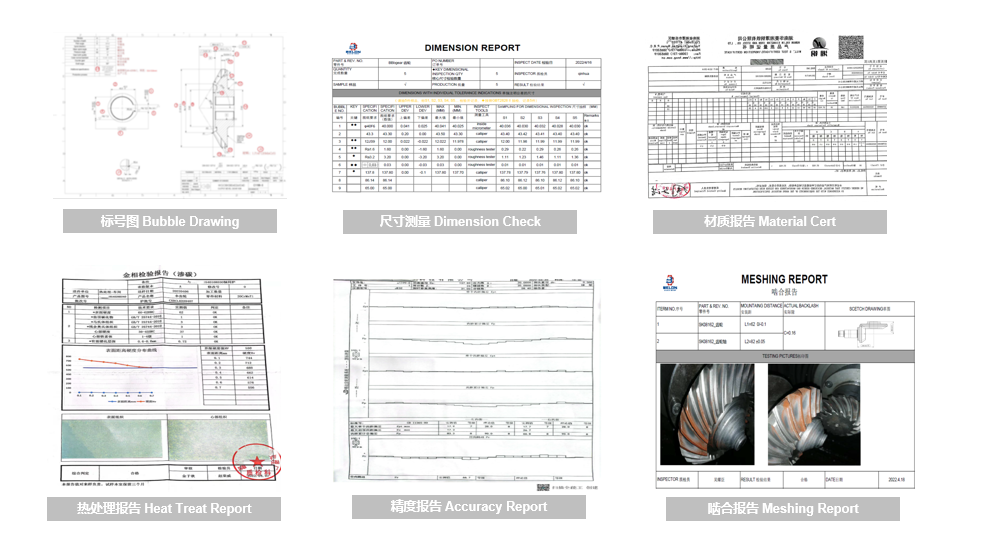

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1)Bubble drawing

2)Dimension report

3)Material cert

4)Heat treat report

5)Ultrasonic Test report (UT)

6)Magnetic Particle Test report (MT)

Meshing test report