Miter gears, strategically integrated within gearboxes, thrive in a multitude of environments owing to their robust design and versatile applications. The 45-degree bevel gear angle makes them particularly adept at smoothly transmitting motion and power in situations where intersecting shafts demand a precise right angle. This versatility extends to diverse usage scenarios, from demanding industrial machinery setups requiring efficient power transmission to intricate automotive systems necessitating controlled changes in the rotation direction. Miter gears shine in their ability to adapt, offering reliability and precision across a spectrum of environments, underscoring their indispensable role in complex mechanical systems.

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

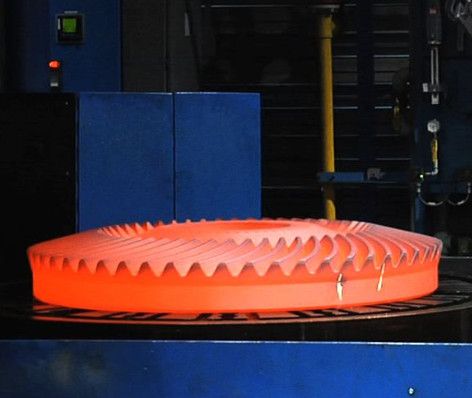

Forging

Lathe turning

Milling

Heat treatment

OD/ID grinding

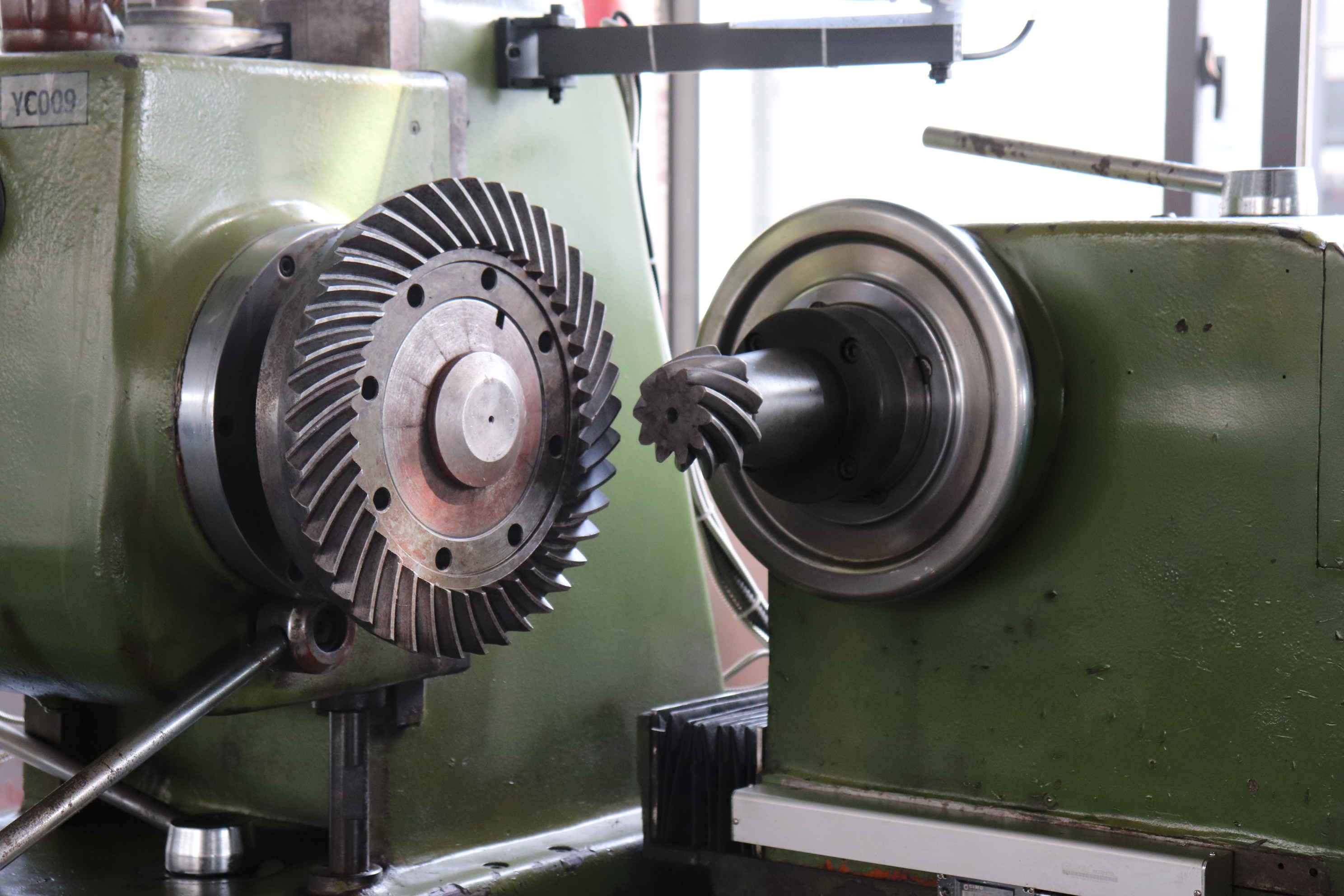

Lapping

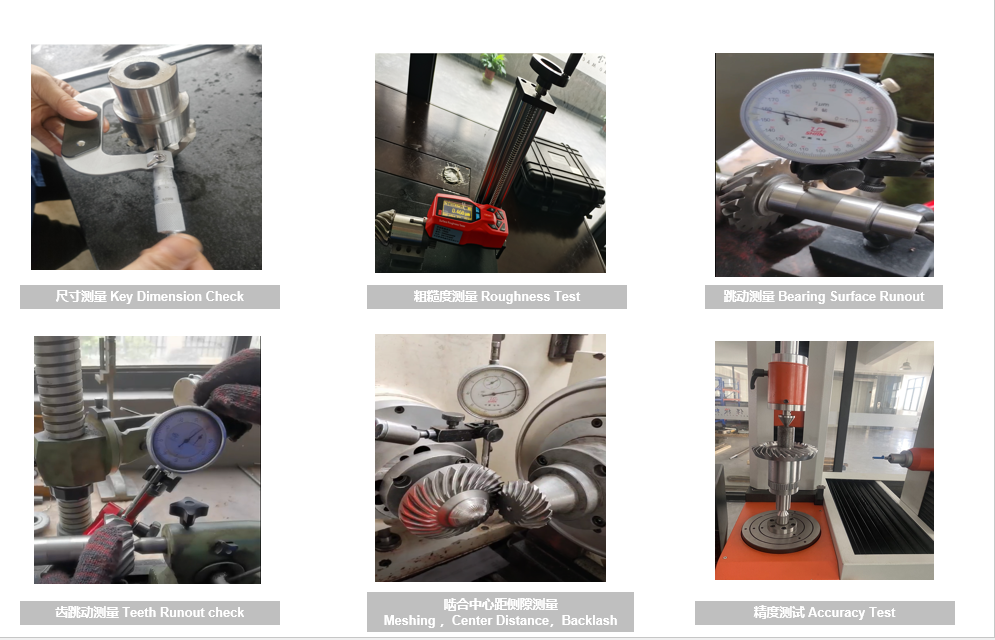

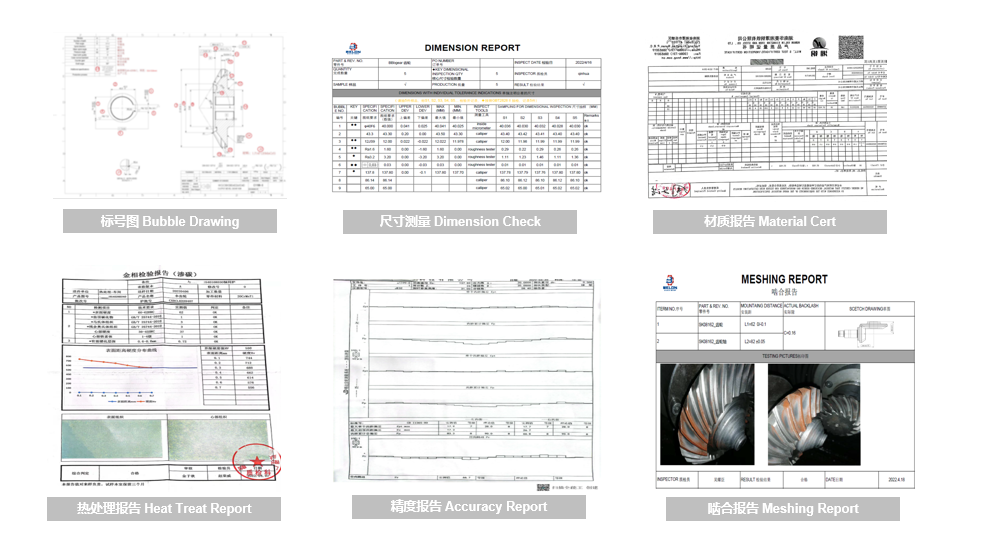

Reports : we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Inner package

Inner package

Carton

wooden package