8 Year Exporter Main Shaft – spline shaft used in automotive motors – Belon Detail:

Production Process:

1) Forging 8620 raw material into bar

2) Pre-Heat Treat (Normalizing or Quenching)

3) Lathe Turning for rough dimensions

4) Hobbing the spline (below video you could check how to hob the spline)

5) https://youtube.com/shorts/80o4spaWRUk

6) Carburizing heat treatment

7) Testing

Manufacturing Plant :

Top ten enterprises in china ,equipped with 1200 staff ,obtained total 31 inventions and 9 patents .Advanced manufacturing equipment ,heat treat equipment ,inspection equipment .All processes from raw material to finish was done in house ,strong engineering team and quality team to meet and beyond customer’s requirement .

Manufacturing Plant

Inspection

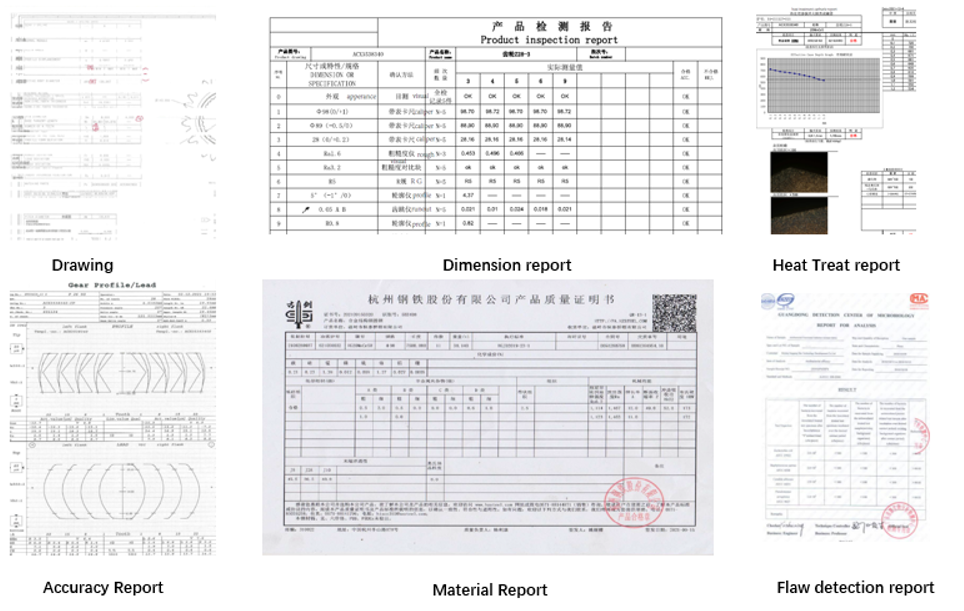

Reports

We will provide below reports also customer’s required reports before every shipping for customer to check and approve .

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

How the hobbing process to make spline shafts

How to do ultrasonic cleaning for spline shaft ?

Hobbing spline shaft

Hobbing spline on bevel gears

how to broaching internal spline for gleason bevel gear

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for 8 Year Exporter Main Shaft – spline shaft used in automotive motors – Belon , The product will supply to all over the world, such as: Burundi, Bangladesh, Swansea, To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.