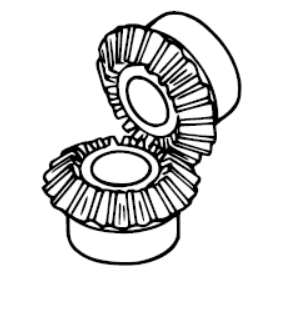

8 Year Exporter Spiral Bevel Gear - Miter Gear Set With Ratio 1:1 – Belon Detail:

Miter gear working method

Advantages of zero bevel gears are:

1)The force acting on the gear is the same as that of a straight bevel gear.

2) Higher strength and lower noise than straight bevel gears (in general).

3) Gear grinding can be done to obtain high-precision gears .

Manufacturing Plant

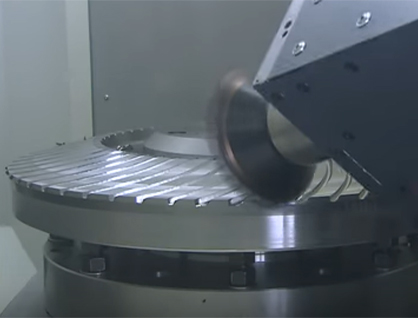

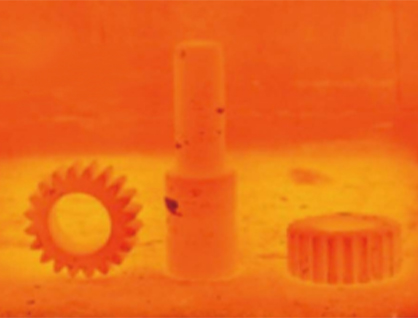

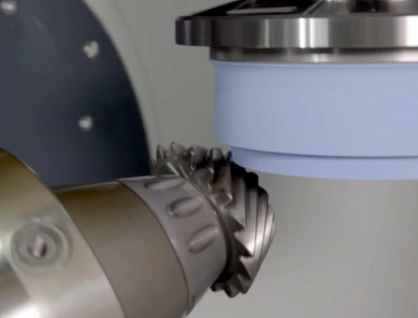

Production Process

Raw Material

Rough Cutting

Turning

Quenching And Tempering

Gear Milling

Heat Treat

Gear Grinding

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

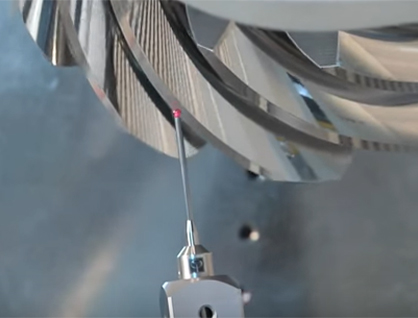

Zero Bevel Gear Milling At Gleason Machine

Product detail pictures:

Related Product Guide:

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for 8 Year Exporter Spiral Bevel Gear - Miter Gear Set With Ratio 1:1 – Belon , The product will supply to all over the world, such as: Thailand, Austria, Cambodia, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

Write your message here and send it to us