Automotive Bevel Gear for Skid Steer Loader Tractors

Our automotive bevel gears are specifically designed to enhance the performance and reliability of skid steer loader tractors in a wide range of applications. Crafted from high-strength, wear-resistant materials, these gears provide exceptional durability and efficiency under heavy workloads and extreme conditions. Engineered with precision, they ensure smooth power transmission and optimized torque distribution, reducing mechanical stress and extending the lifespan of your equipment.

These bevel gears are compatible with most skid steer loader tractor models, making them a versatile and cost-effective choice for operators in construction, agriculture, landscaping, and other demanding industries. Their robust design minimizes vibration and noise, improving overall operational efficiency and operator comfort.

Manufactured to meet strict quality standards, our bevel gears undergo rigorous testing to guarantee reliability and peak performance. Easy to install and maintain, they help reduce downtime and maintenance costs, keeping your tractors running at optimal capacity. Whether you need a replacement gear or an upgrade to improve productivity, our automotive bevel gears are the perfect solution for dependable, long-lasting performance.

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

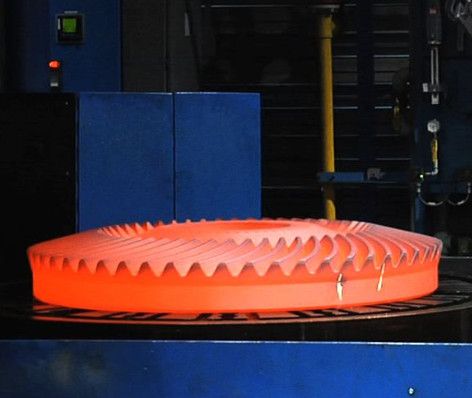

Forging

Lathe turning

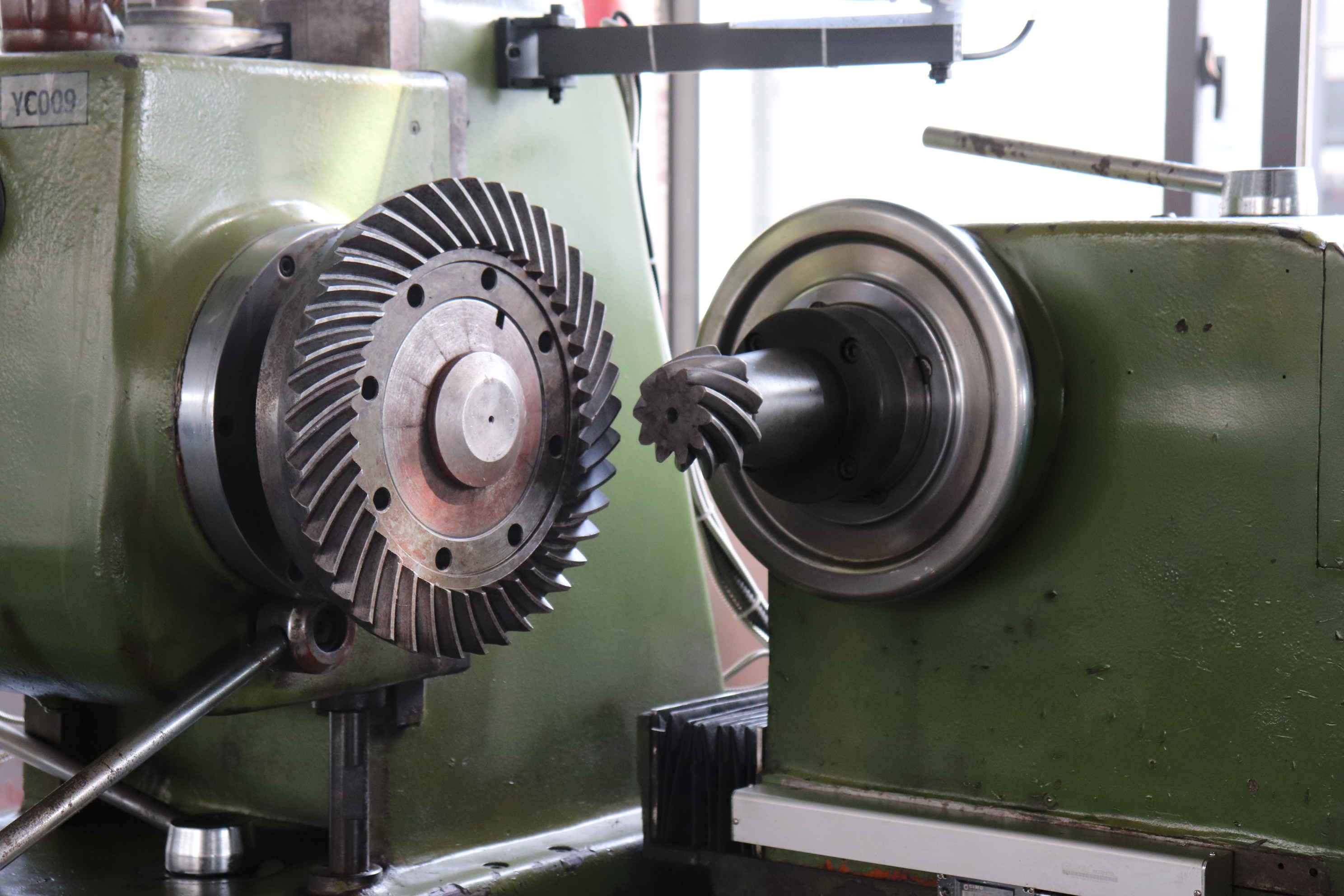

Milling

Heat treatment

OD/ID grinding

Lapping

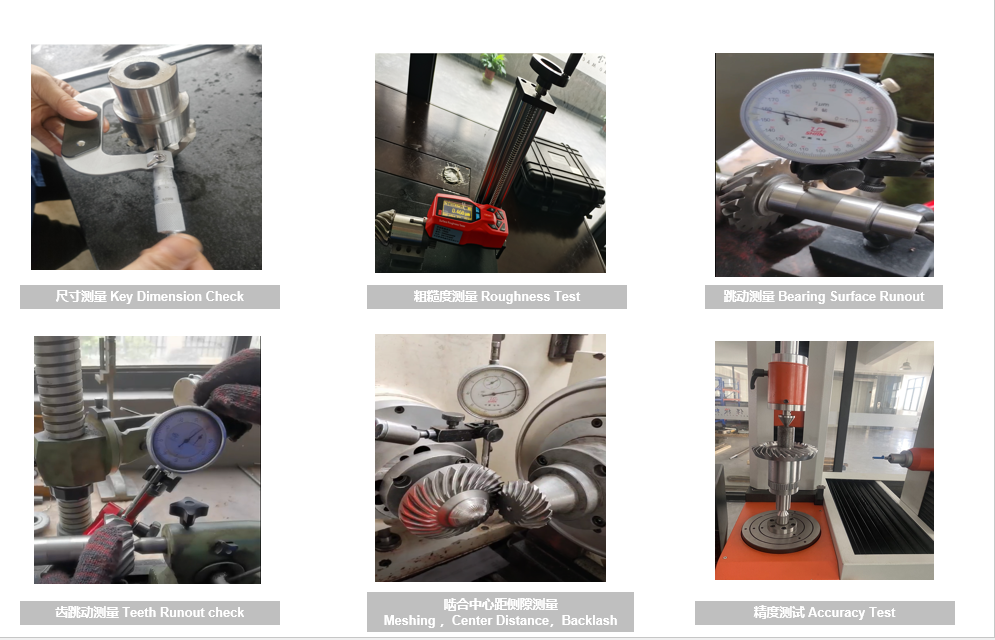

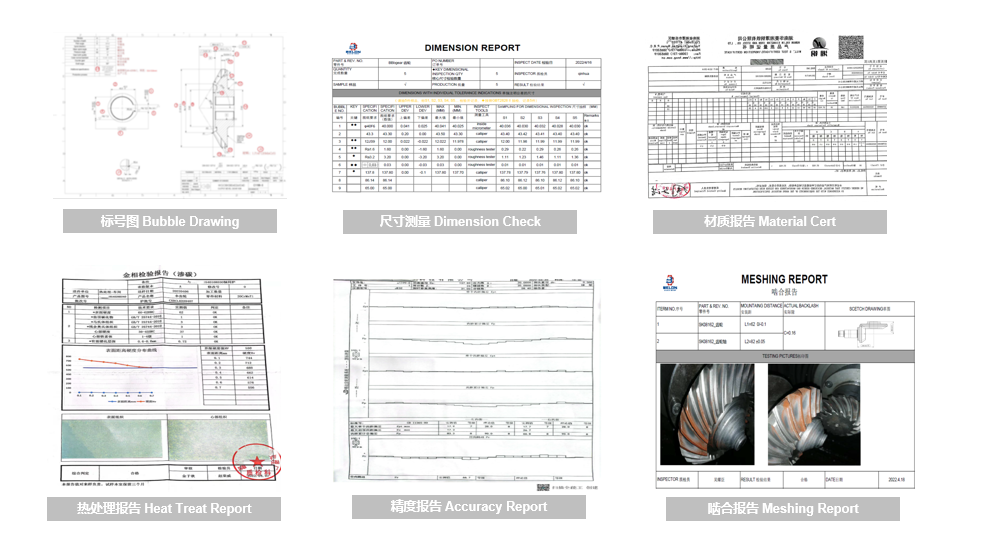

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Inner package

Inner package

Carton

wooden package