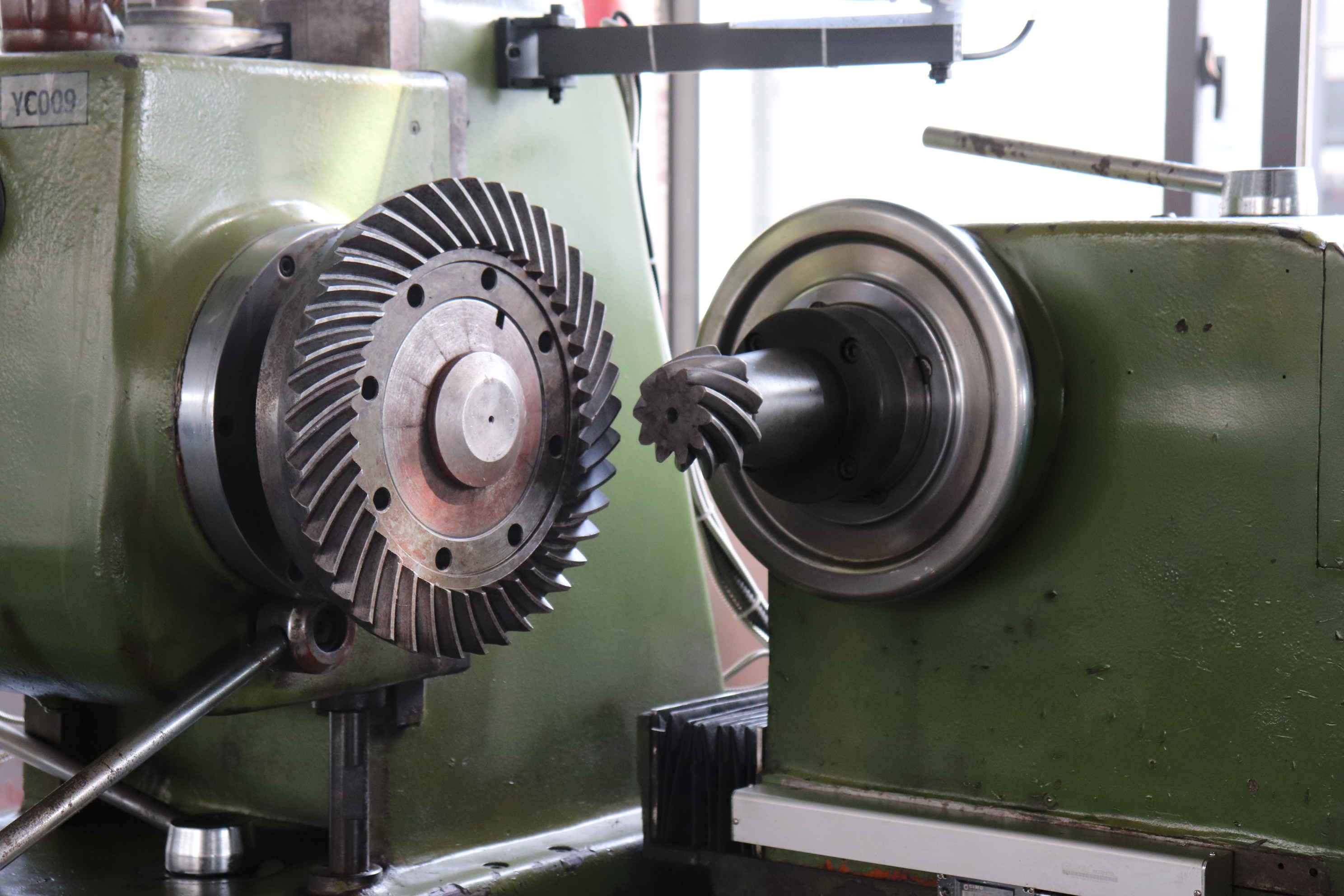

Bevel gears are essential components in marine gearboxes, facilitating the efficient transfer of power from the engine to the propeller. Their unique design allows for a change in drive direction, making them ideal for compact marine applications. Crafted from durable materials, bevel gears withstand harsh marine environments, ensuring reliable performance and longevity. By providing smooth operation and minimizing friction, they enhance overall efficiency and maneuverability of vessels. The precision engineering of bevel gears plays a vital role in optimizing power transmission, making them indispensable for any marine gearbox system. Quality bevel gears are key to successful marine operations

Our products are widely used in various industrial fields, such as automotive, machinery manufacturing, engineering machinery etc., to provide customers with reliable transmission solutions. We are committed to providing our customers with high-quality, high-performance precision gears products to meet the needs of different applications. Choosing our products is a guarantee of reliability, durability, and superior performance.

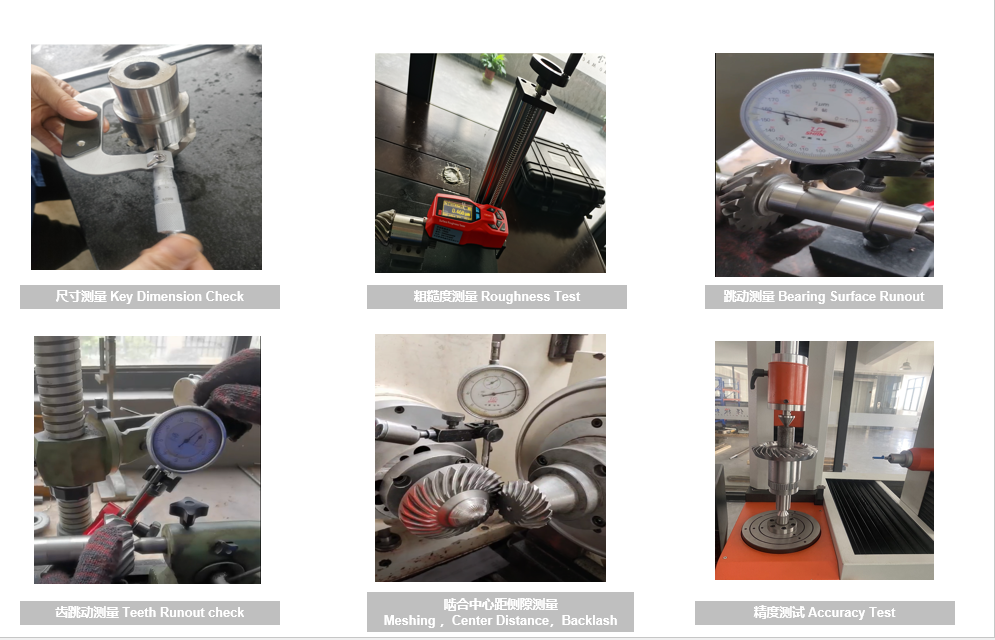

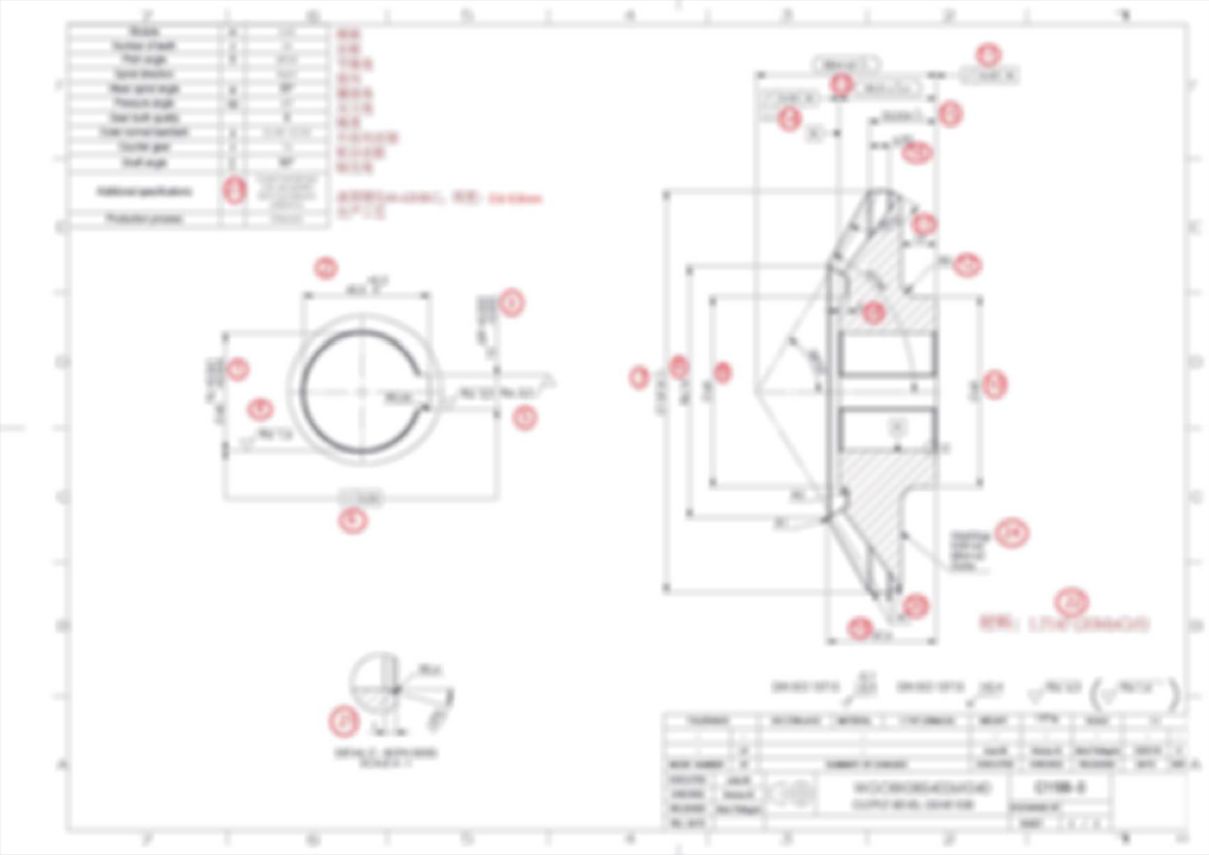

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

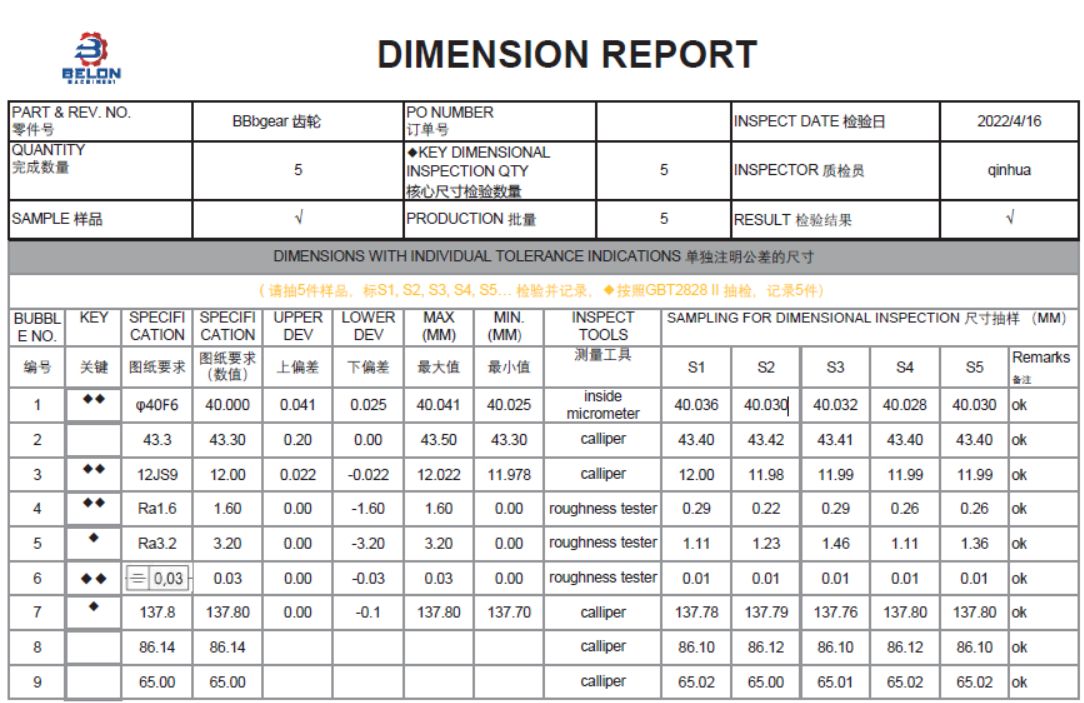

1)Bubble drawing

2)Dimension report

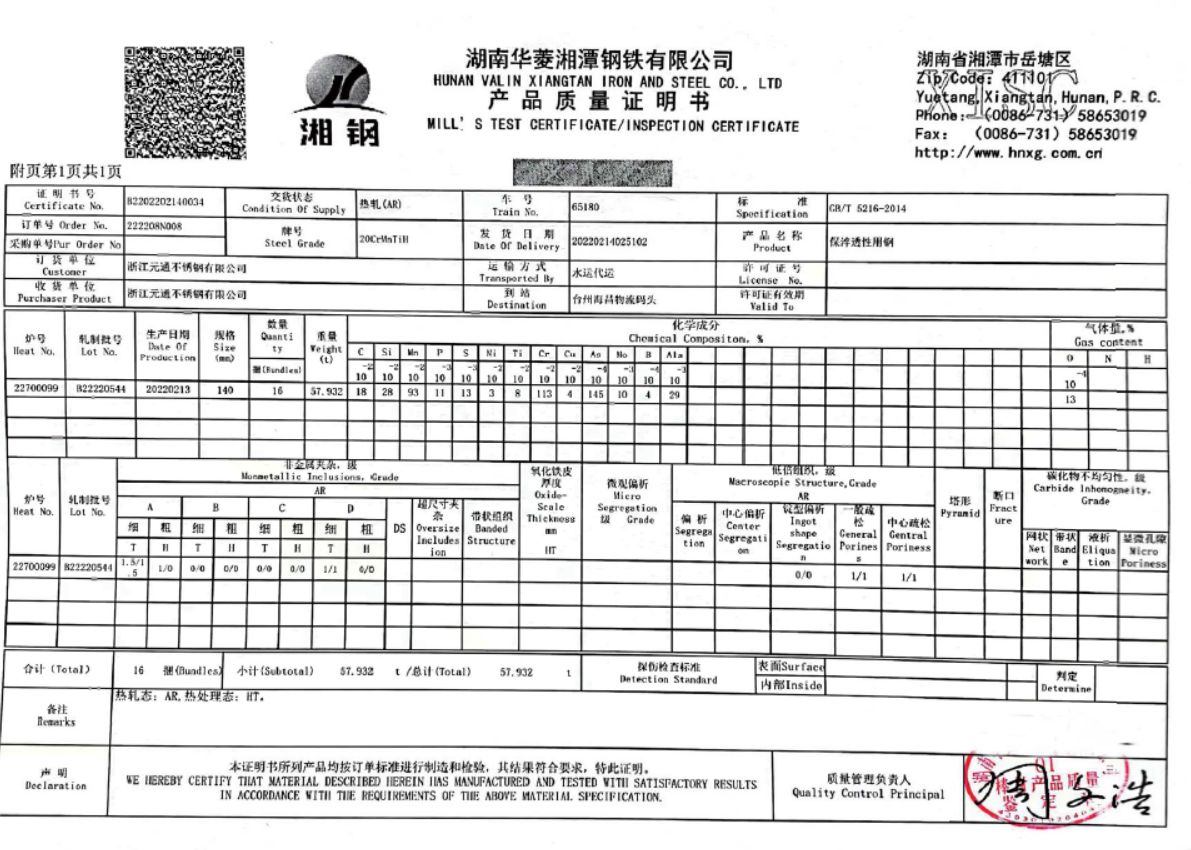

3)Material cert

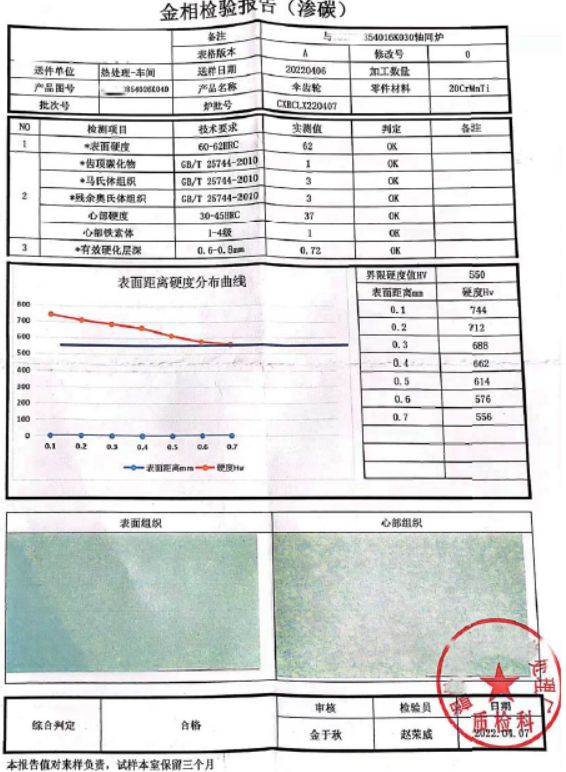

4)Heat treat report

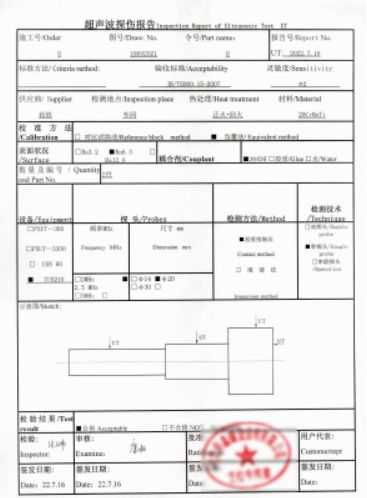

5)Ultrasonic Test report (UT)

6)Magnetic Particle Test report (MT)

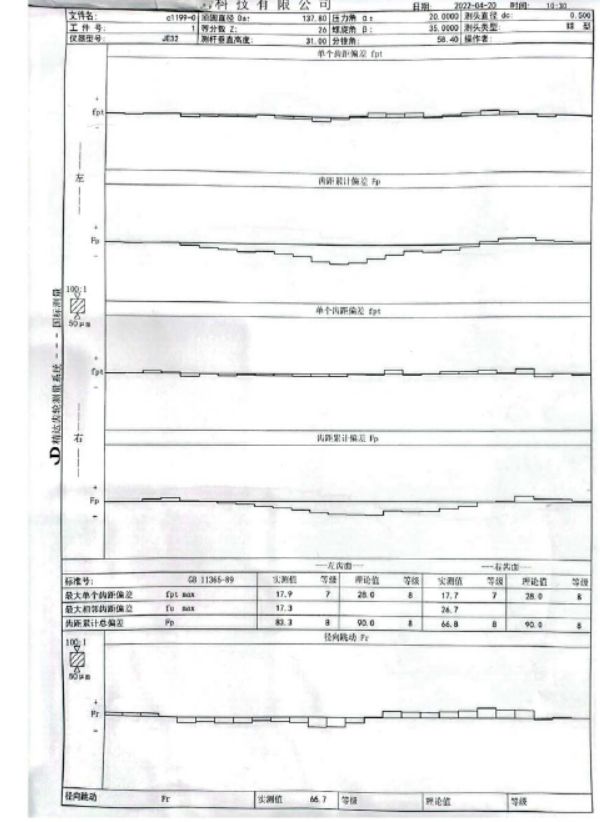

Meshing test report

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

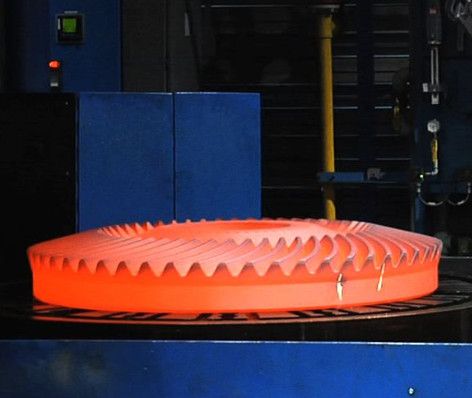

Forging

Lathe turning

Milling

Heat treat

OD/ID grinding

Lapping