Transmission Gear Manufacturers,Crafted using high grade C45# carbon steel, these gears offer exceptional strength and durability, making them a reliable choice for industries such as machine tools, heavy equipment, and vehicles,Straight bevel gear With a straight bevel design, these gears ensure precise 90 degree power transmission, ensuring that your machines operate at peak performance levels.

When it comes to power transmission, precision is key and that's exactly what the C45# Premium Quality Straight Bevel Gears deliver. Their superior design enables them to deliver consistent power transfer, regardless of the application whether you're using them in gearboxes, rudders or drive shafts, these gears will give you unrivalled efficiency, reliability, and precision you need.

The company has introduced Gleason Phoenix 600HC and 1000HC gear milling machines, which can process Gleason shrink teeth, Klingberg and other high gears; and Phoenix 600HG gear grinding machine, 800HG gear grinding machine, 600HTL gear grinding machine, 1000GMM, 1500GMM gear The detector can do closed-loop production, improve the processing speed and quality of products, shorten the processing cycle, and achieve fast delivery.

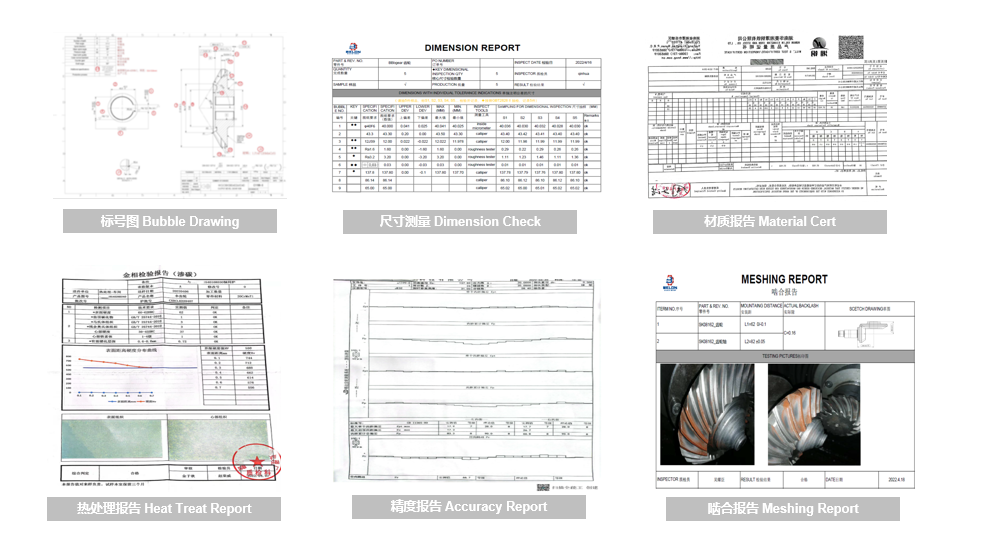

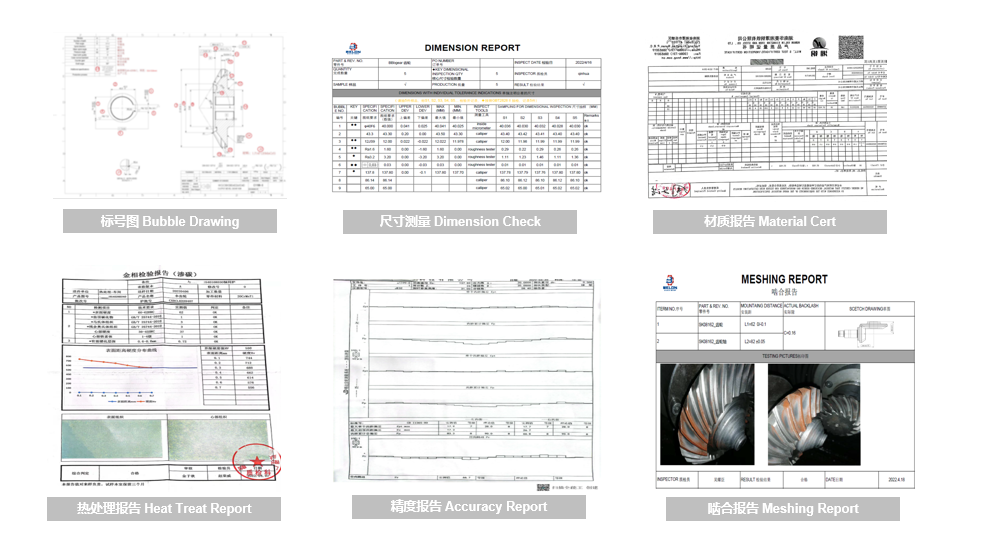

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1)Bubble drawing

2)Dimension report

3)Material cert

4)Heat treat report

5)Ultrasonic Test report (UT)

6)Magnetic Particle Test report (MT)

7)Meshing test report