China Factory Spiral Bevel Gear Manufacturers Detail:

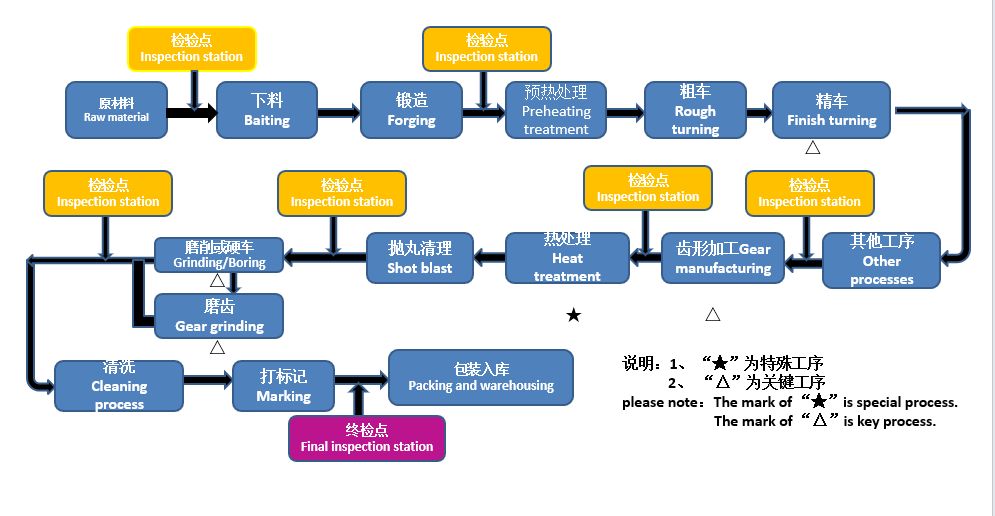

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

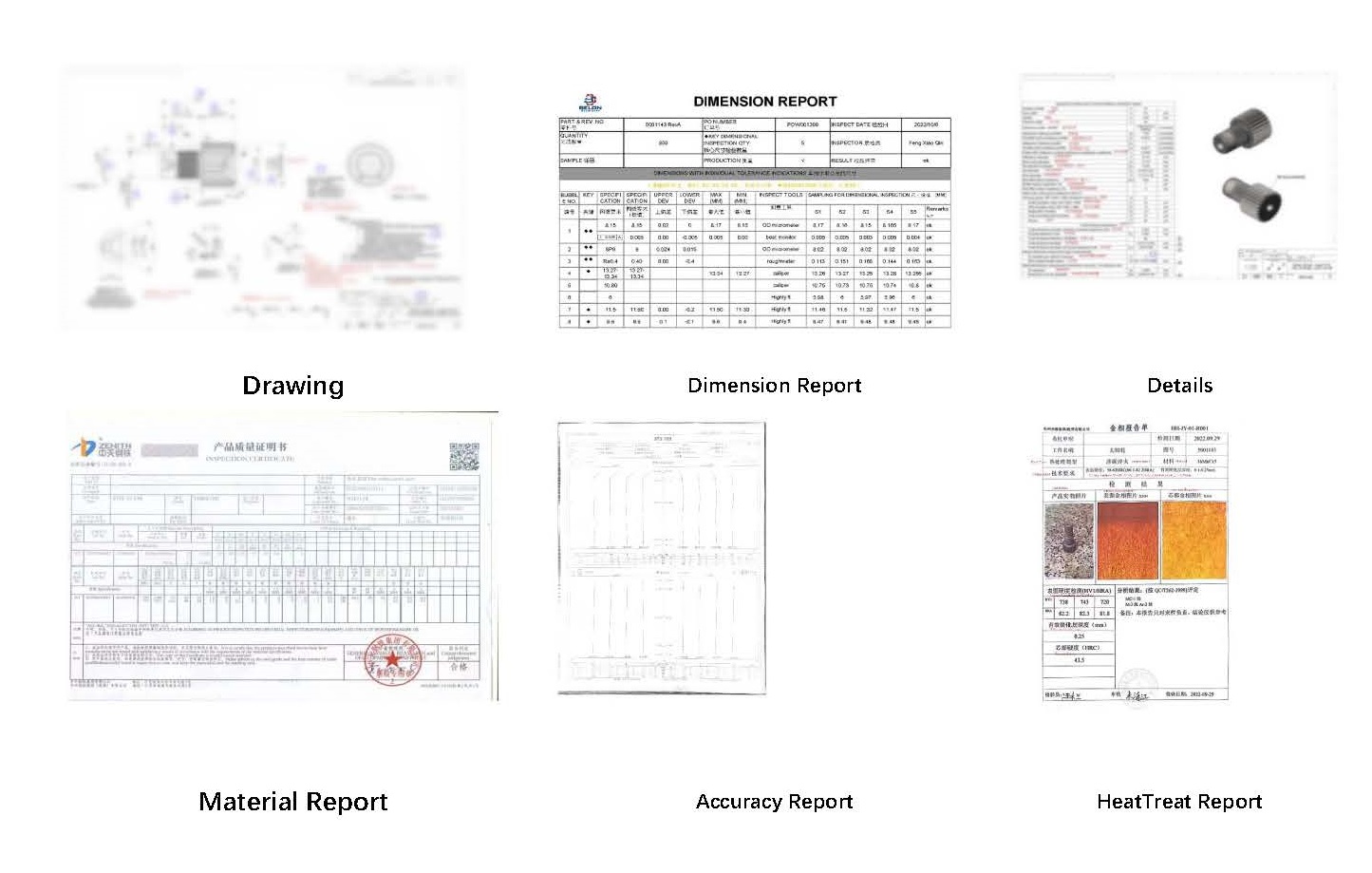

Reports

Packages

Our video show

Product detail pictures:

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for China Factory Spiral Bevel Gear Manufacturers , The product will supply to all over the world, such as: Puerto Rico, Namibia, Amsterdam, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

Write your message here and send it to us