China Herringbone Gear for Marine Heavy Machinery Automotive Systems Detail:

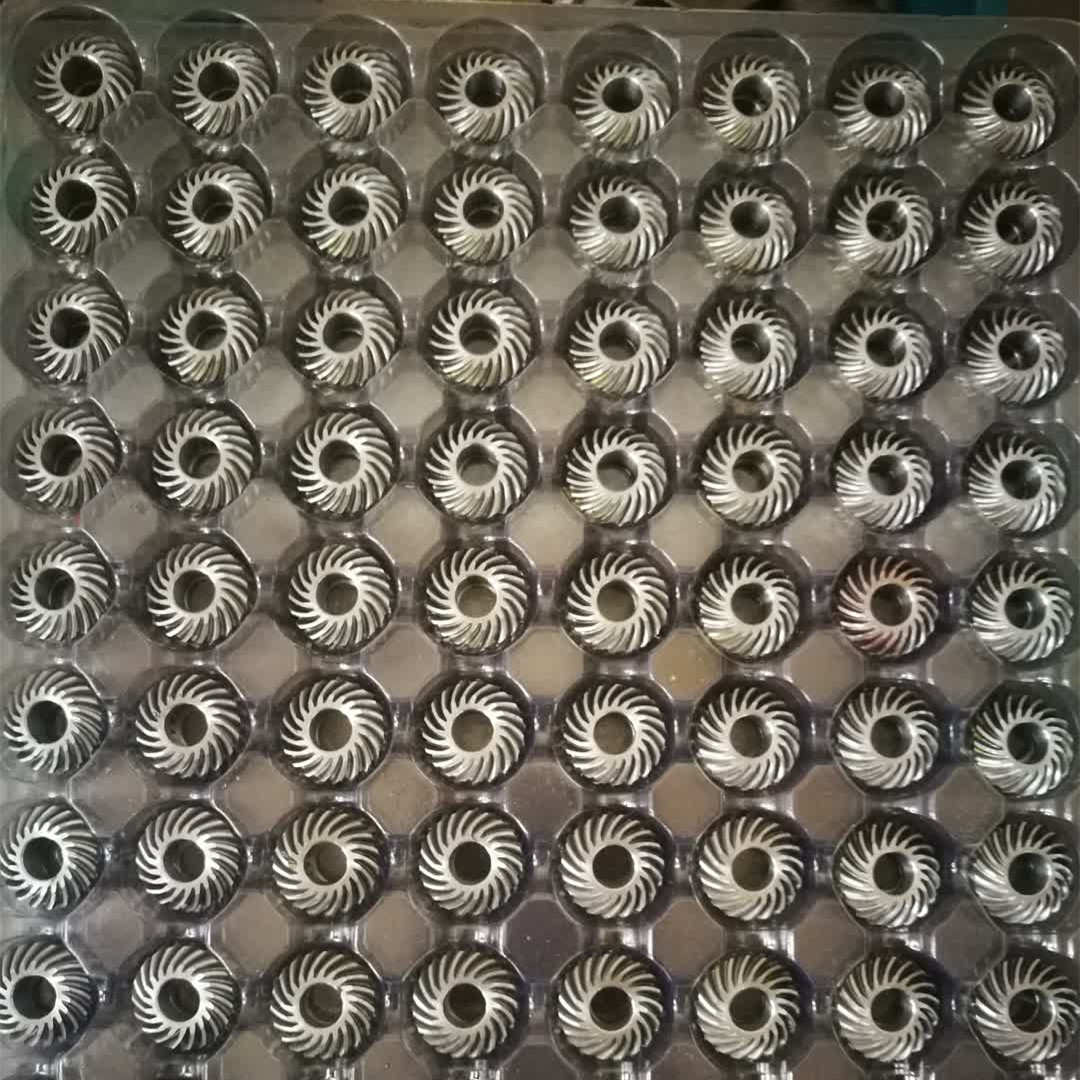

Belon gears Manufacturing herringbone gears involves various processes, including hobbing, grinding, and milling. Hobbing is often used as the primary process for shaping the teeth, where a hob tool cuts the gear profile into the metal. Grinding follows to refine the teeth’s surface, ensuring high precision and a smooth finish, which is crucial for minimizing friction. Finally, milling can be applied to achieve specific modifications, enhancing the gear’s adaptability in specialized machinery.

Herringbone gears are highly reliable in applications requiring durability and precision, such as in marine engines, heavy machinery, and automotive systems. These gears are ideal for industries prioritizing robust and quiet operations.

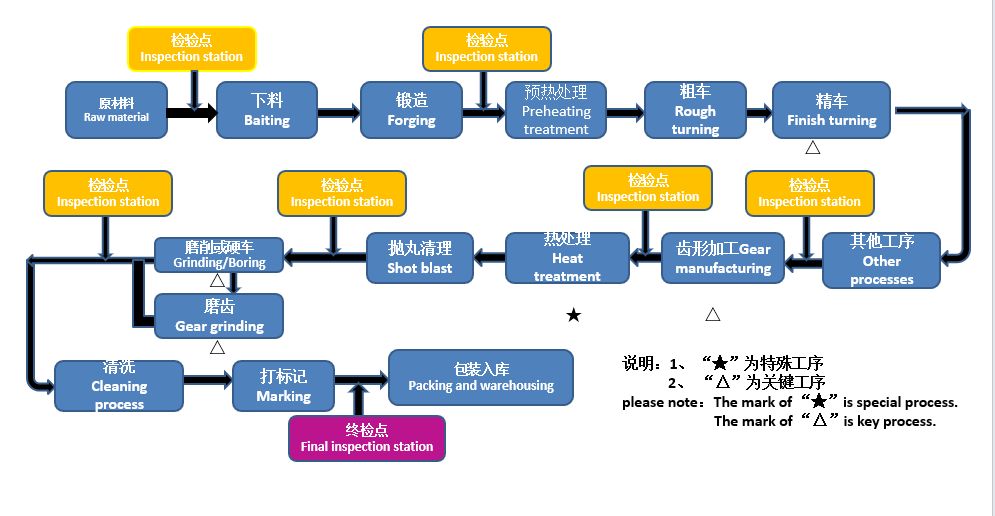

How to control the process quality and when to do the process inspection process ? This chart is clear to view .The important process for cylindrical gears .Which reports should be created during each process ?

Here is the whole production process for this helical gear

1) Raw material 8620H or 16MnCr5

1) Forging

2) Pre-heating normalizing

3) Rough turning

4) Finish turning

5) Gear hobbing

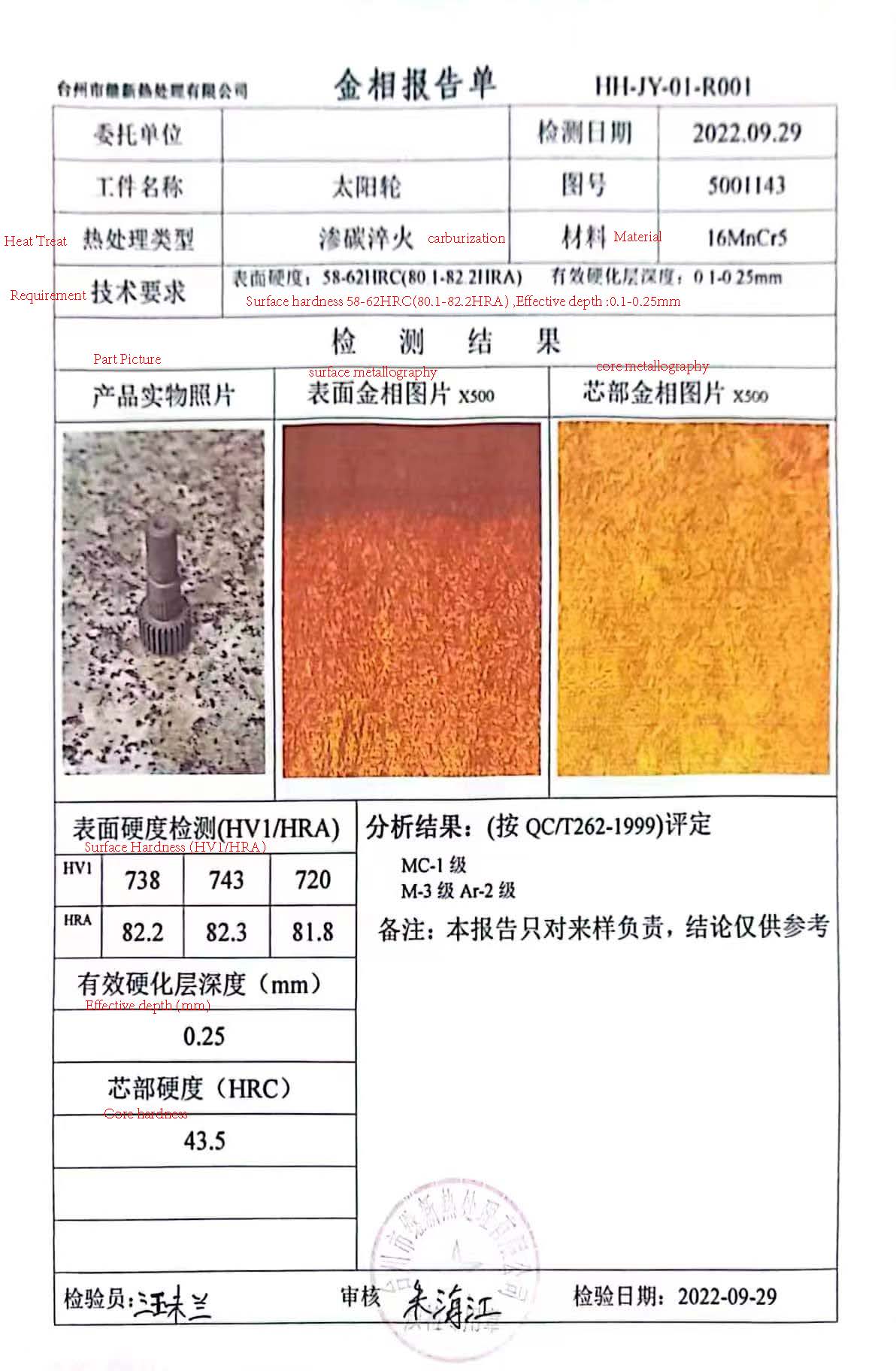

6) Heat treat carburizing 58-62HRC

7) Shot blasting

8) OD and Bore grinding

9) Helical gear grinding

10) Cleaning

11) Marking

12) Package and warehouse

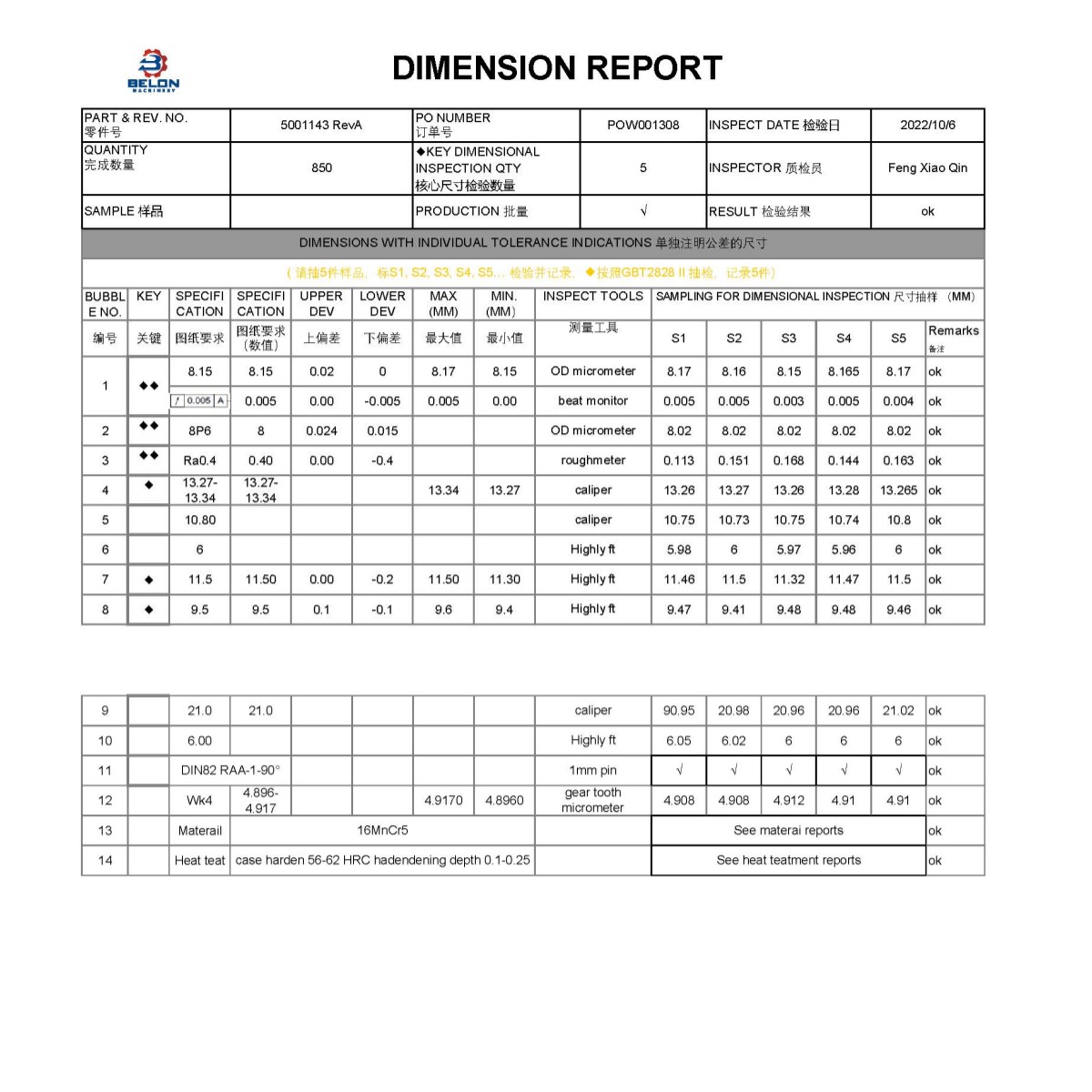

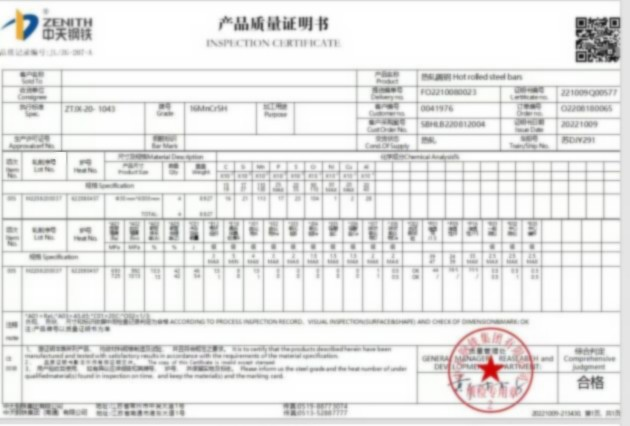

We will provide full quality files before shipping for customer’s view and approval .

1)Bubble drawing

2)Dimension report

3)Material cert

4)Heat treat report

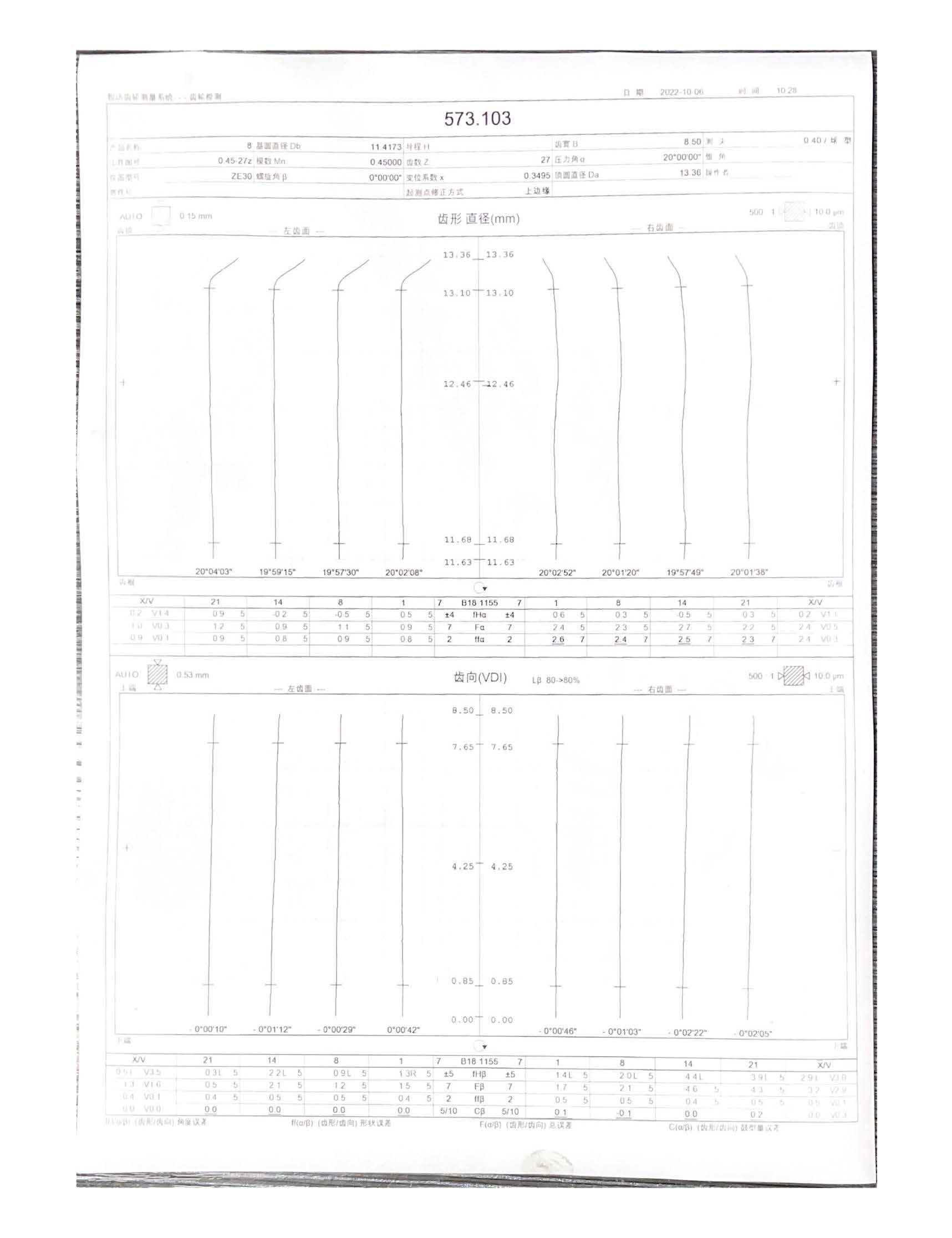

5)Accuracy report

6)Part pictures ,videos

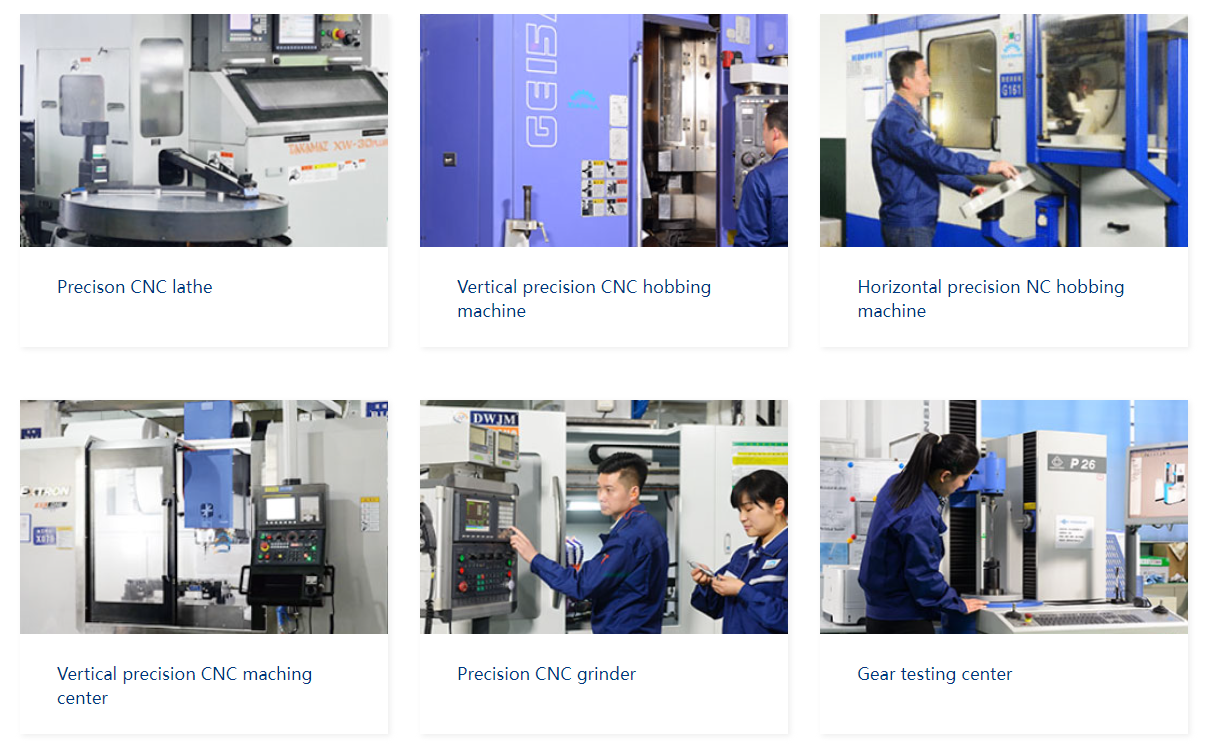

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

forging

grinding

hard turning

heat treatment

hobbing

quenching & tempering

soft turning

testing

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

Packages

Our video show

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for China Herringbone Gear for Marine Heavy Machinery Automotive Systems , The product will supply to all over the world, such as: Jamaica, US, Slovakia, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.