Chinese Professional Gear Hypoid - Hypoid Gear Set With High Speed Ratio For Industrial Robots – Belon Detail:

What is hypoid bevel gear ?

The conical surface is used as the indexing surface, which approximately replaces the drop wheel of the end truncated surface far from the throat on the hyperbola.

Features of hypoid gears:

1. When facing the teeth of the big wheel, place the small wheel horizontally on the right side of the big wheel. If the axis of the small shaft is below the axis of the big wheel, it is called a downward offset, otherwise it is an upward offset.

2. As the offset distance increases, the helix angle of the small wheel also increases, and the outside diameter of the small wheel also increases. In this way, the rigidity and strength of the small wheel can be improved, and the number of teeth of the small wheel can be reduced, and a high reduction ratio transmission can be obtained.

The advantages of hypoid gears:

1. It can reduce the position of the driving bevel gear and the drive shaft, thus lowering the center of gravity of the body and the vehicle, which is beneficial to improve the driving stability of the car

2. The offset of the gear makes the number of teeth of the driving gear less, and a pair of gears can obtain a larger transmission ratio

3. The overlap coefficient of the hyperboloid gear meshing is relatively large, the strength is higher when working, the carrying capacity is large, the noise is smaller, the transmission is more stable, and the service life is long.

Manufacturing Plant

China the first one to import USA UMAC technology for hypoid gears .

Production Process

Raw Material

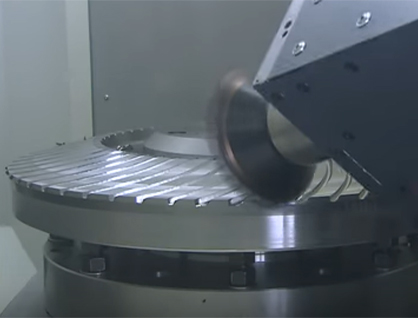

Rough Cutting

Turning

Quenching And Tempering

Gear Milling

Heat Treat

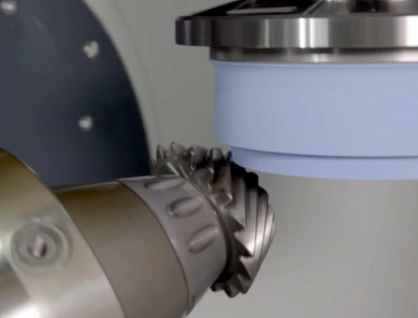

Gear Grinding

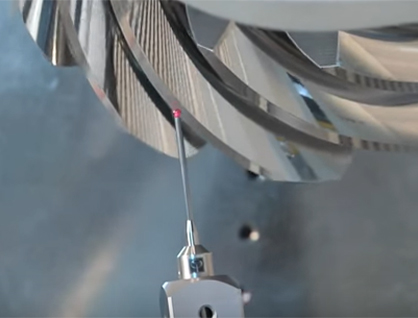

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

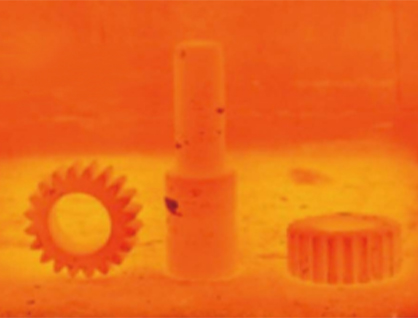

Our video show

Hypoid Gears

Km Series Hypoid Gears For Hypoid Gearbox

Hypoid Bevel Gear In Industrial Robot Arm

Hypoid Bevel Gear Milling & Mating Testing

Hypoid Gear Set Used In Mountain Bike

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Chinese Professional Gear Hypoid - Hypoid Gear Set With High Speed Ratio For Industrial Robots – Belon , The product will supply to all over the world, such as: Italy, Brisbane, Surabaya, We'd like to invite customers from abroad to discuss business with us. We can present our clients with high quality products and excellent service. We're sure that we'll have good cooperative relationships and make a brilliant future for both parties.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!