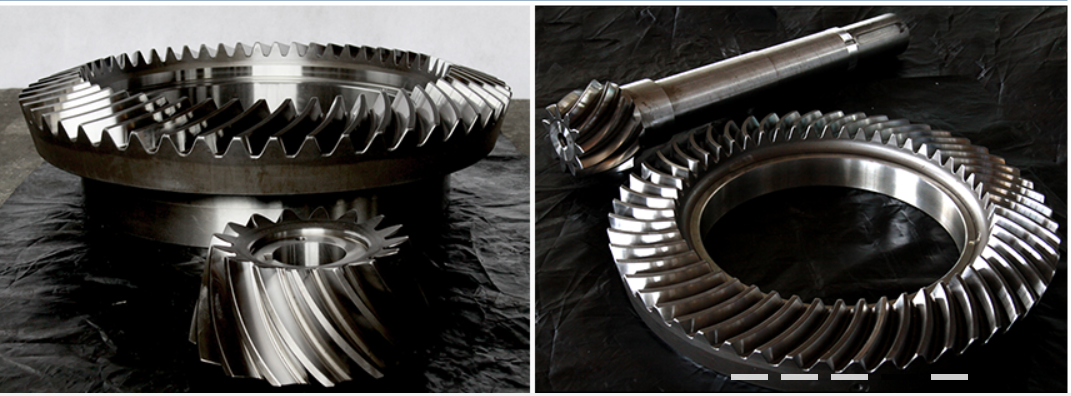

Coniflex bevel gear kit gears and shaft for spiral bevel gear gearbox

Our Large Klingelnberg Bevel Gear, featuring advanced Hard Cutting gearTeeth technology is a coveted component within the realms of mechanical engineering and manufacturing. Its reputation for exceptional manufacturing quality and unmatched durability positions it as a standout choice in the industry. The distinctive characteristic of this bevel gear lies in the incorporation of hard-cutting teeth technology, a cutting edge feature that significantly enhances its performance.

Belon gear reliable heavy-duty gear solutions for high load, high torque industrial gearboxes

The implementation of hard cutting teeth imparts the gear with exceptional wear resistance, ensuring its reliability even in demanding environments with high loads. This makes the Large Bevel Gear ideal for applications that necessitate precision transmission, where durability and longevity are paramount considerations.

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1) Bubble drawing

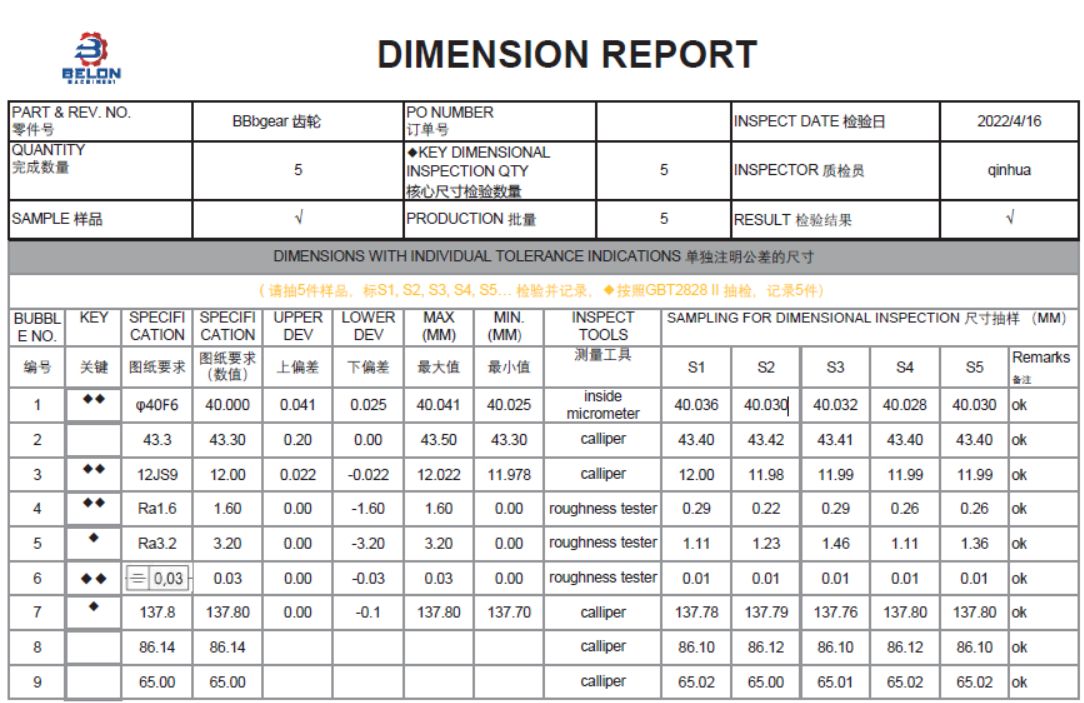

2) Dimension report

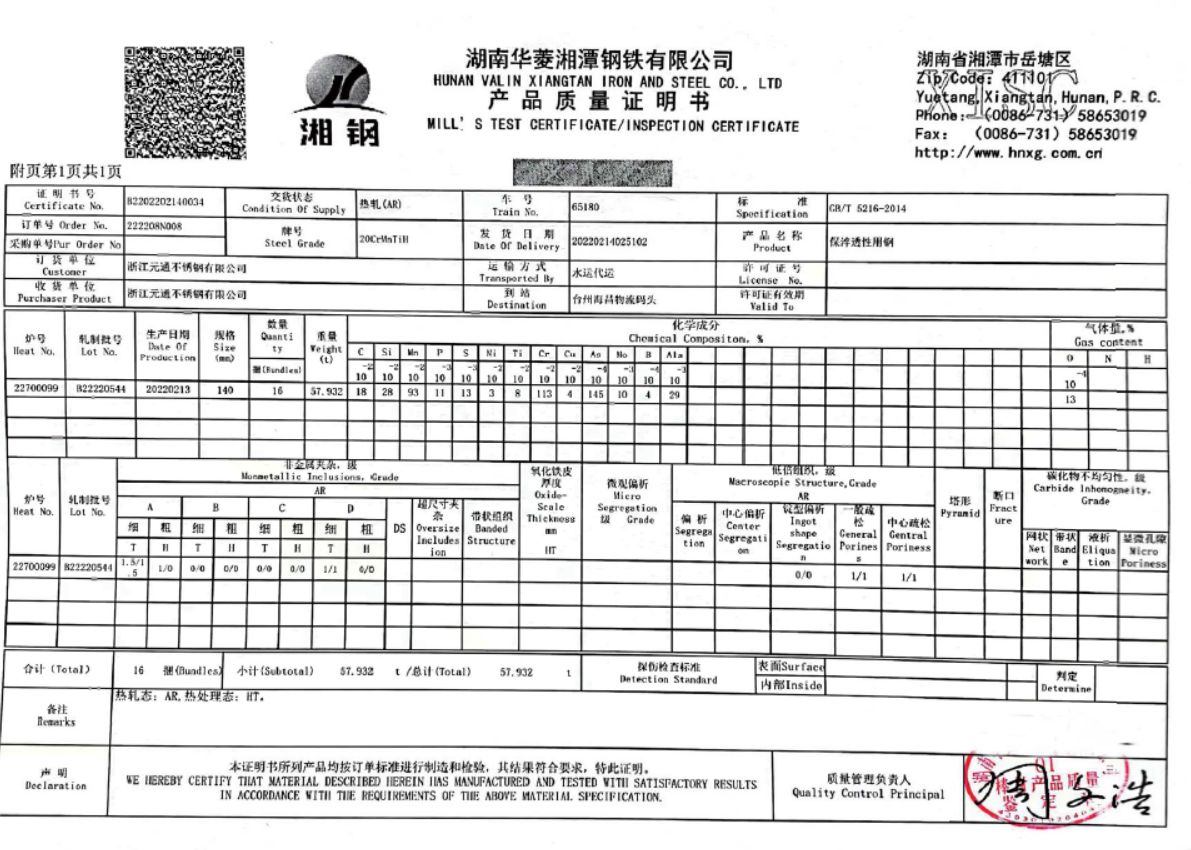

3) Material cert

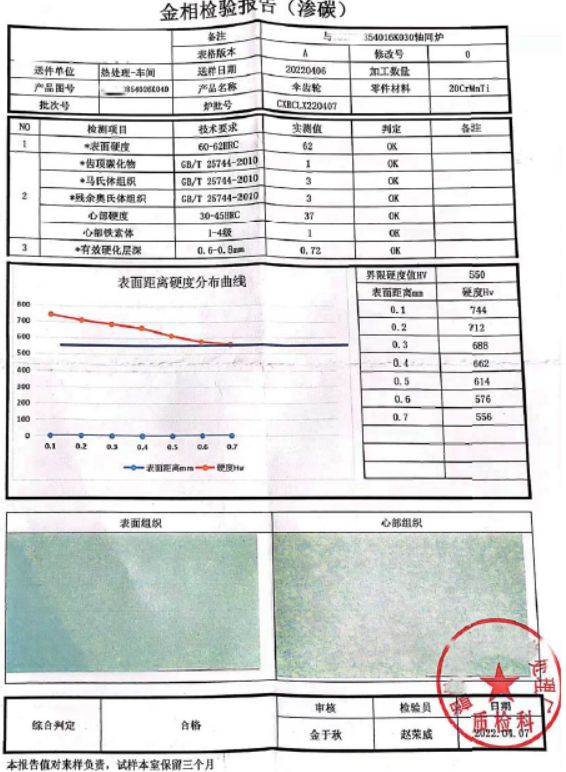

4) Heat treat report

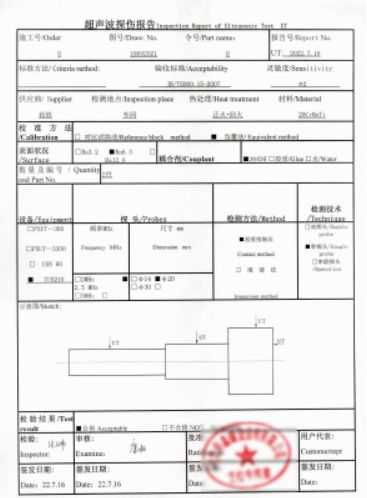

5) Ultrasonic Test report (UT)

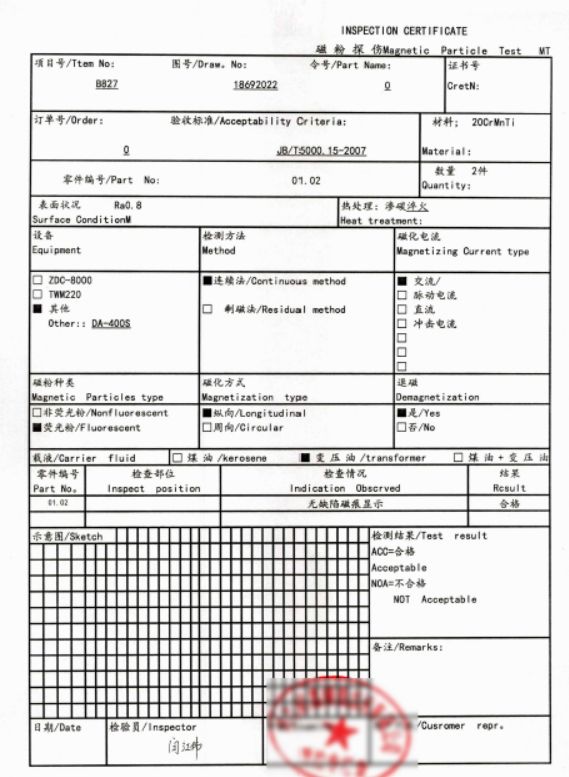

6) Magnetic Particle Test report (MT)

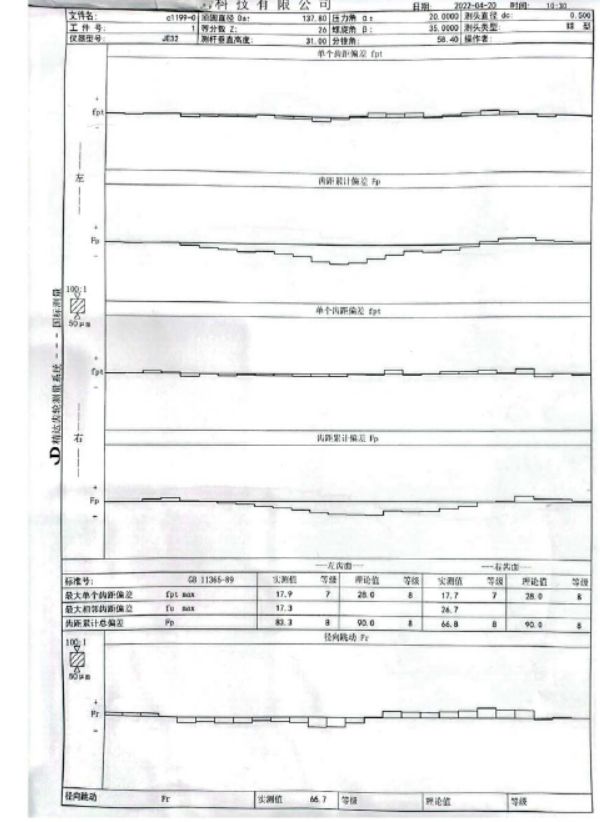

7) Meshing test report

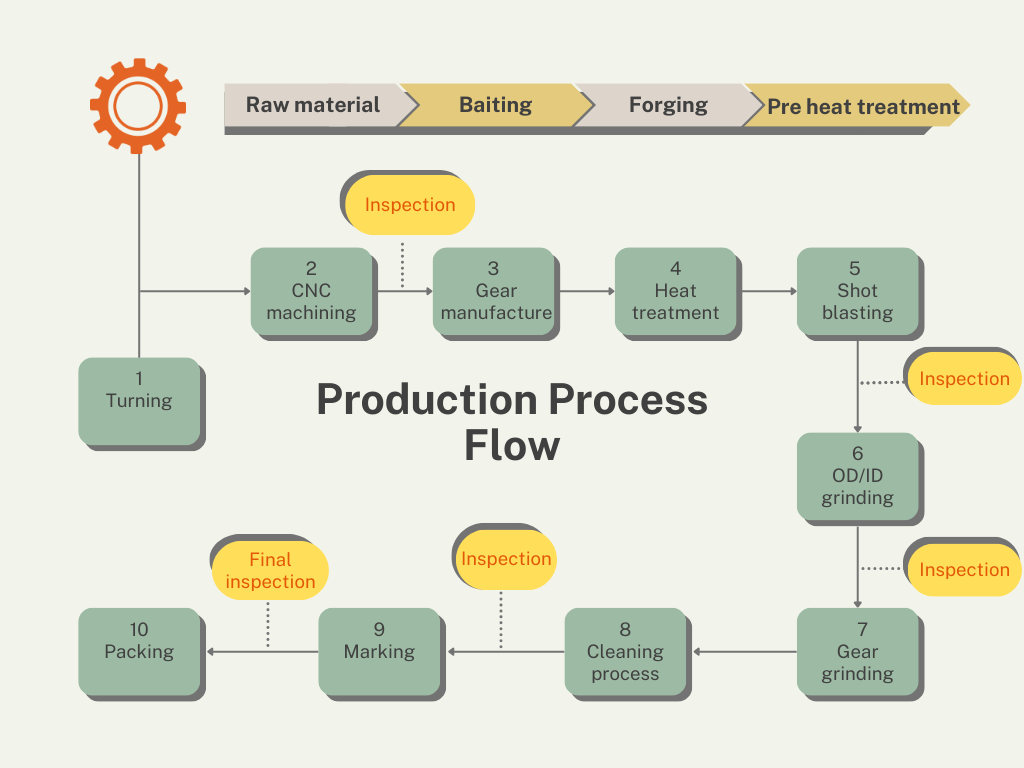

Klingelnberg bevel gear production process turning raw material baiting forging pre heat treatment Inspection CNC machining gear manufacture heat shot blasting,OD/ID grinding gear grinding cleaning process marking and packing

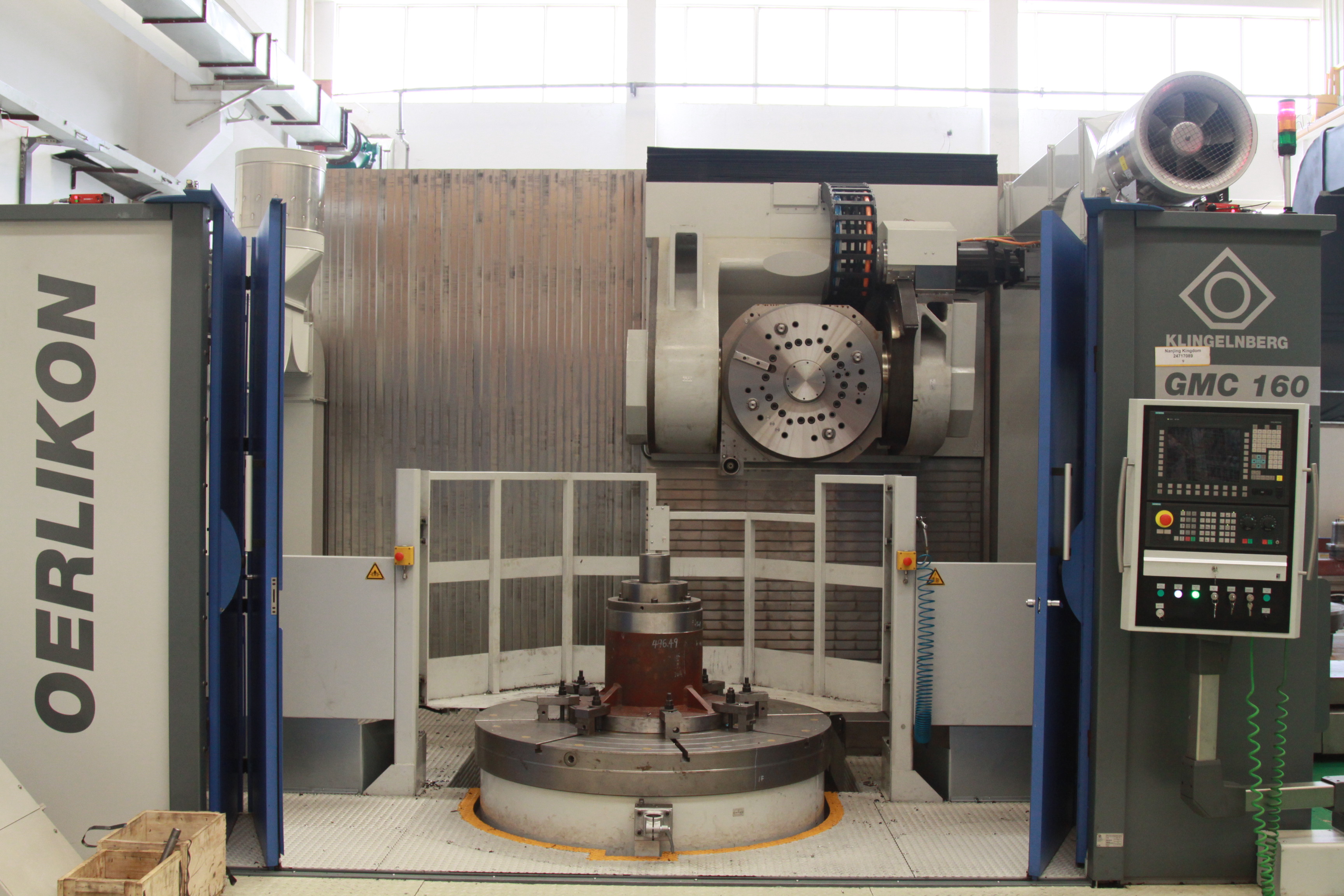

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

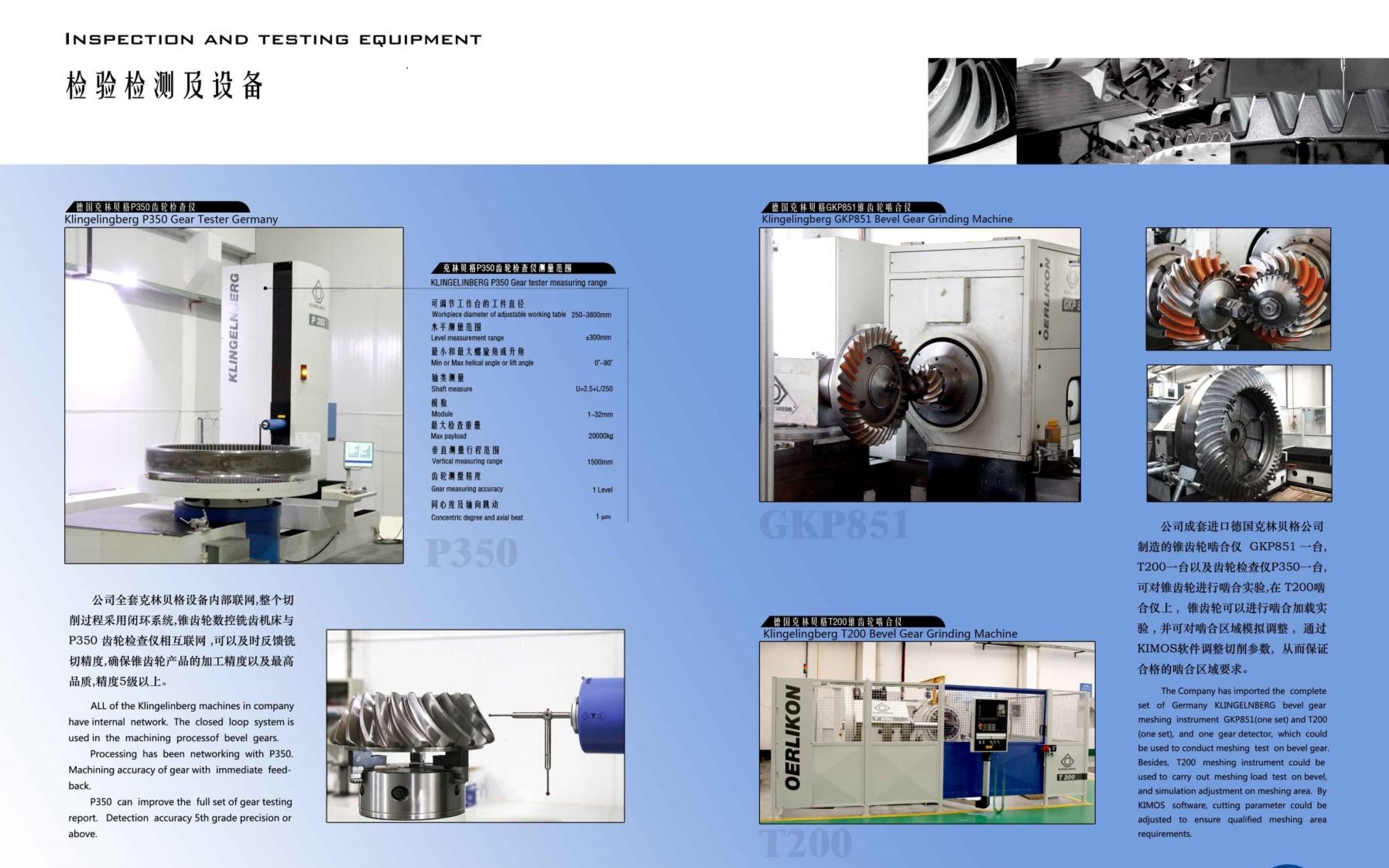

All of the Klingelinberg machines in company have internal network. The closed loop system is used in the machining processof bevel gears.Processing has been networking with P350. Machining accuracy of gear with immediate feedback.P350 can improve the full set of gear testing report. Detection accuracy 5th grade precision or above.

Our Company has imported the complete set of Germany KLINGELNBERG bevel gear meshing instrument GKP851(one set) and T200 (one set), and one gear detector, which could be used to conduct meshing test on bevel gear. Besides, T200 meshing instrument could be used to carry out meshing load test on bevel, and simulation adjustment on meshing area. By KIMOS software, cutting parameter could be adjusted to ensure qualified meshing area requirements.