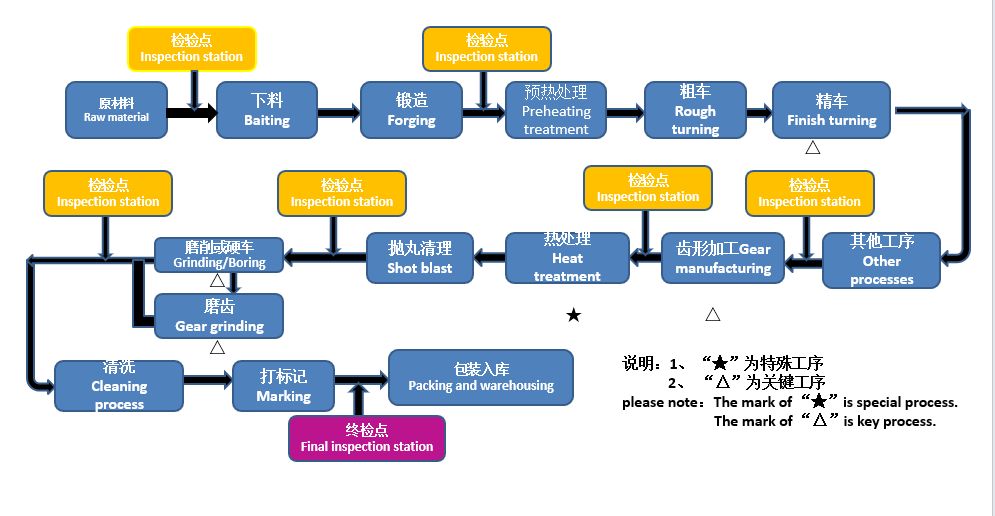

Inspection

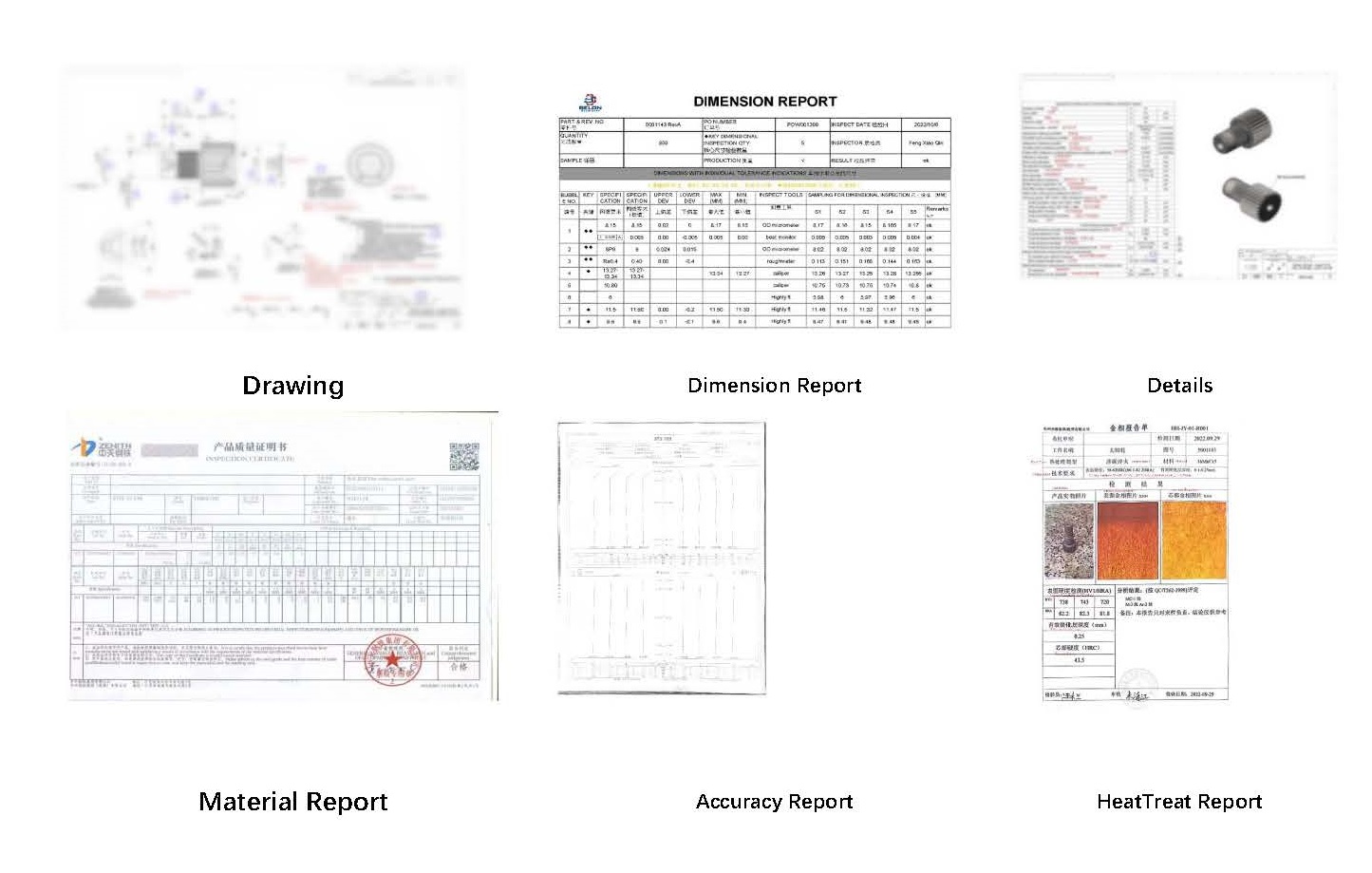

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

Reports

Packages

Our video show

Write your message here and send it to us