OEM Skew Bevel Gears Used In Bevel Gear Reducer Gearbox Detail:

Types Of Reducer Gear OEM ODM Design Grinding Crown Bevel Gears Used In Reducer Gearbox In an era of interconnected technologies, we understand the importance of connectivity and smart functionality. Our gear systems are designed with compatibility in mind, seamlessly integrating with digital monitoring and control systems. This connectivity not only enhances ease of use but also facilitates predictive maintenance, reducing downtime and enhancing overall system efficiency.

As part of our commitment to quality control, we implement rigorous testing procedures throughout the manufacturing process. This guarantees that each gear system leaving our facilities adheres to the highest standards, contributing to a reputation for reliability and consistency.

http://https://www.belongear.com/types-of-reducer-gear/

Custom Bevel Gears Supplier ,Our products helical bevel gears are widely used in various industrial fields, such as automotive, machinery manufacturing, engineering machinery, etc., to provide customers with reliable transmission solutions. We are committed to providing our customers with high-quality, high-performance precision gear products to meet the needs of different applications. Choosing our products is a guarantee of reliability, durability, and superior performance.

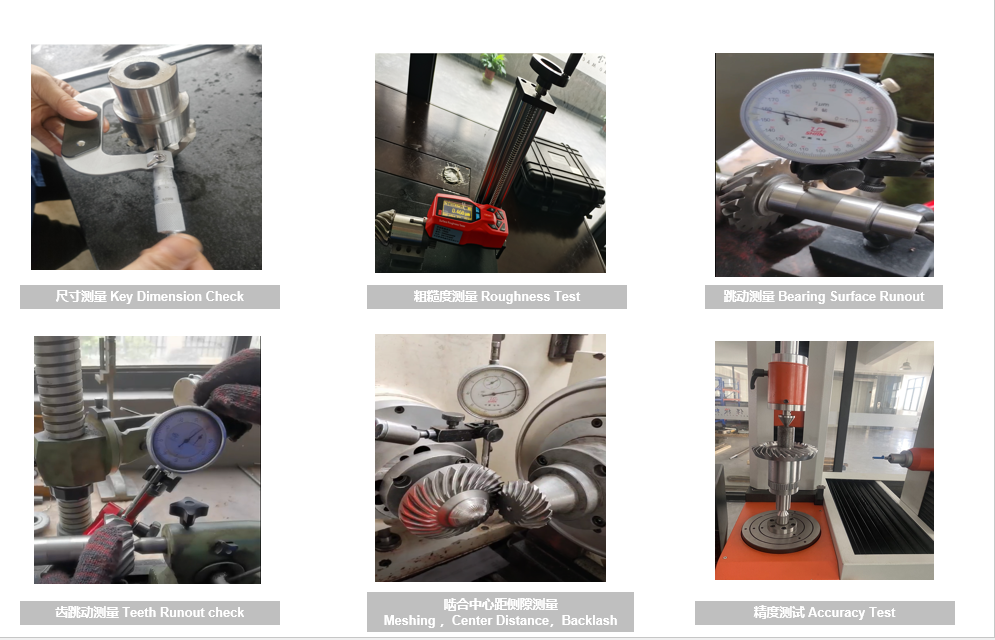

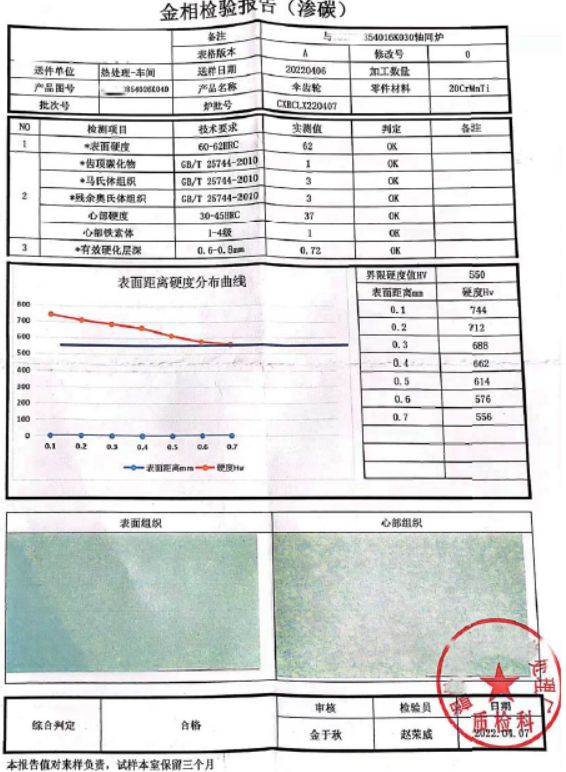

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

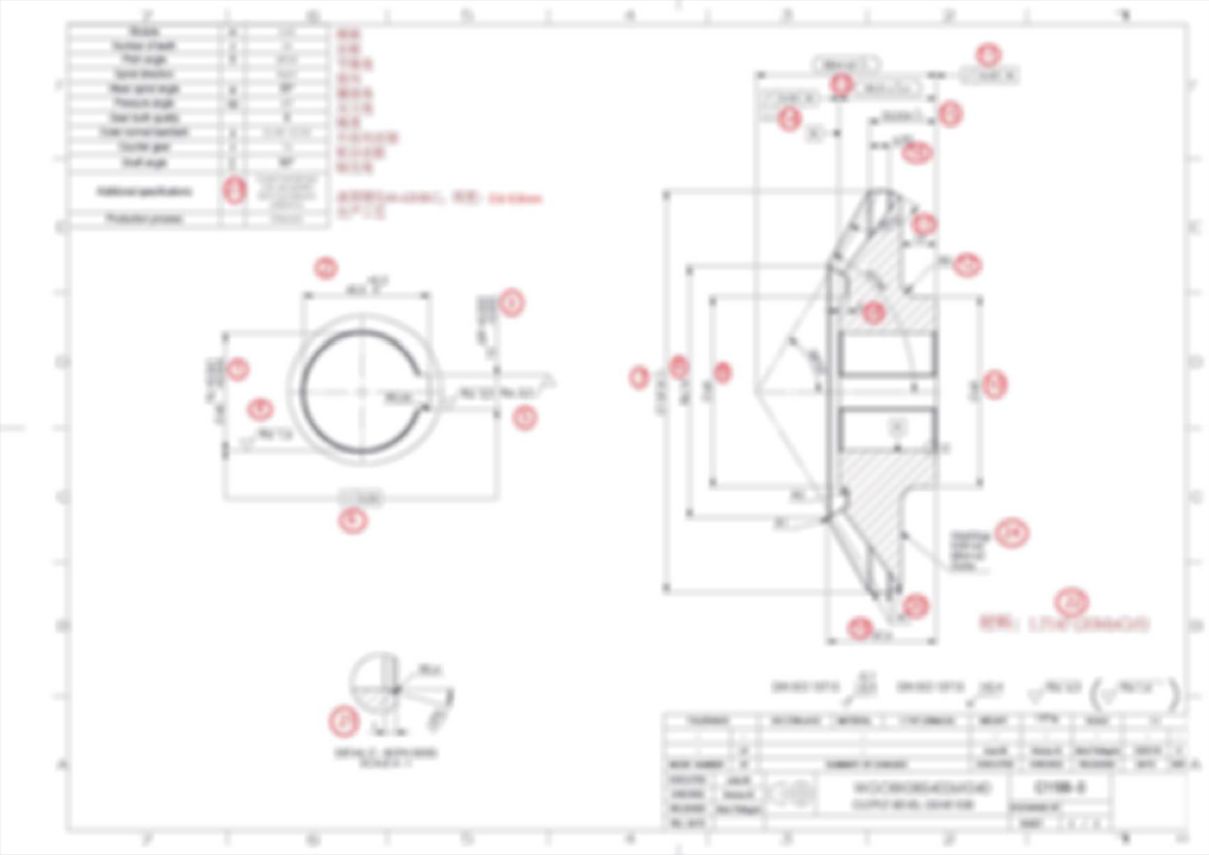

1)Bubble drawing

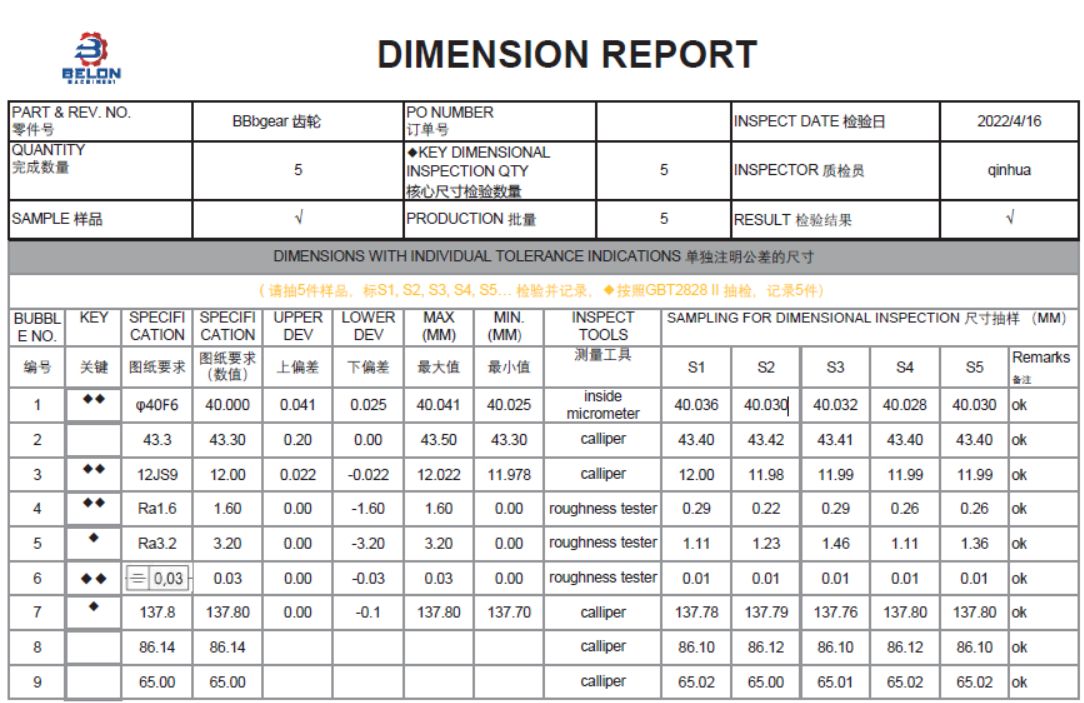

2)Dimension report

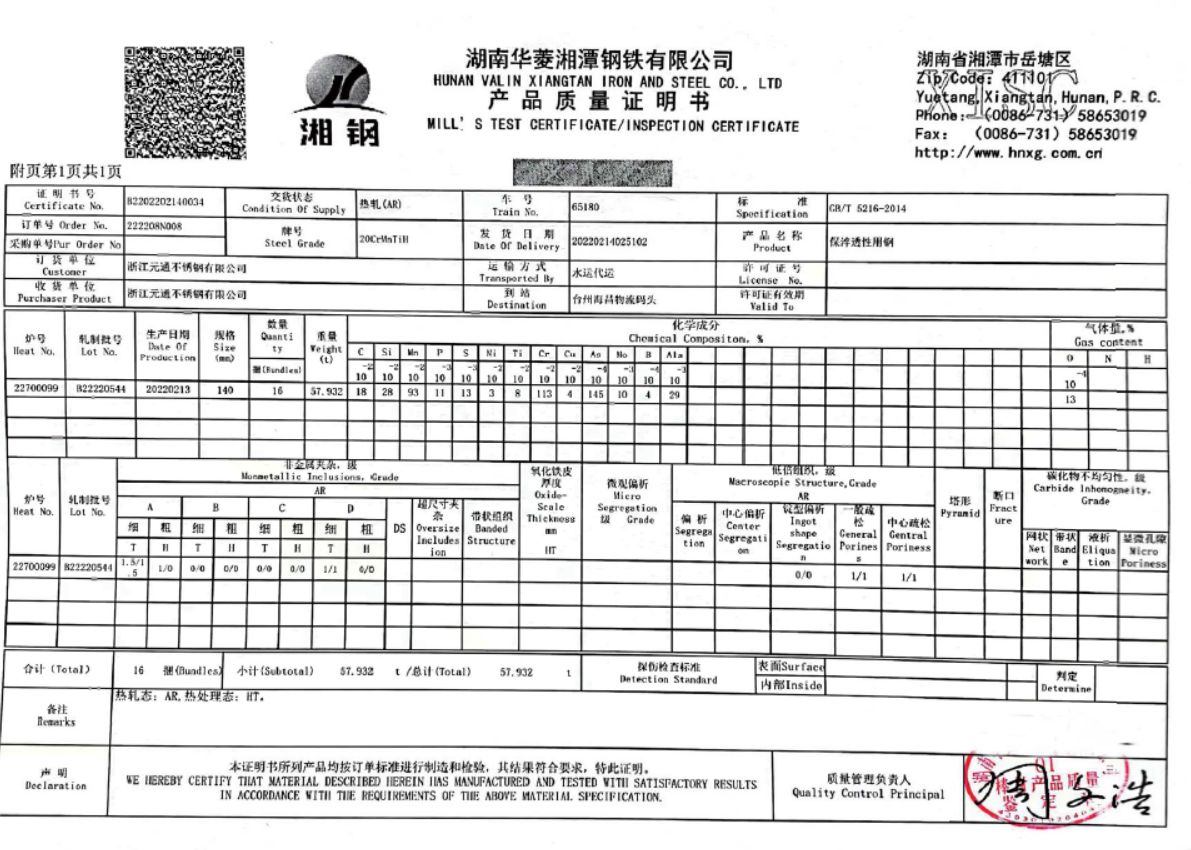

3)Material cert

4)Heat treat report

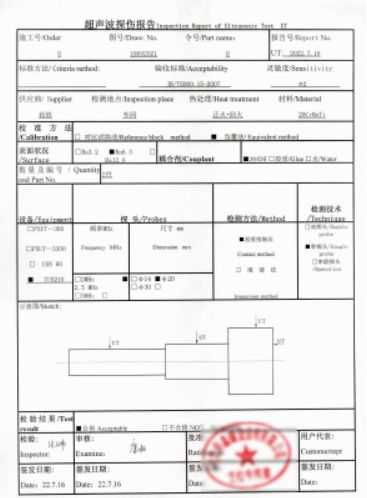

5)Ultrasonic Test report (UT)

6)Magnetic Particle Test report (MT)

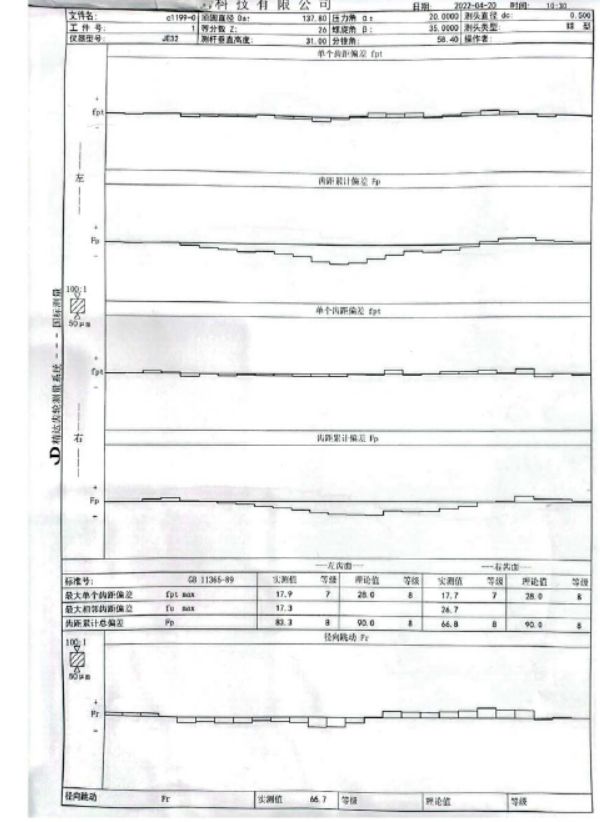

Meshing test report ,Inspection bevel gears :Key Dimension Check、Roughness Test、Bearing Surface Runout 、Teeth Runout check,Meshing 、Center Distance, Backlash、Accuracy Test

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

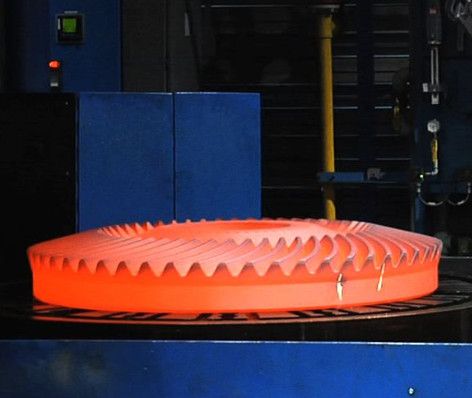

Forging

Lathe turning

Milling

Heat treat

OD/ID grinding

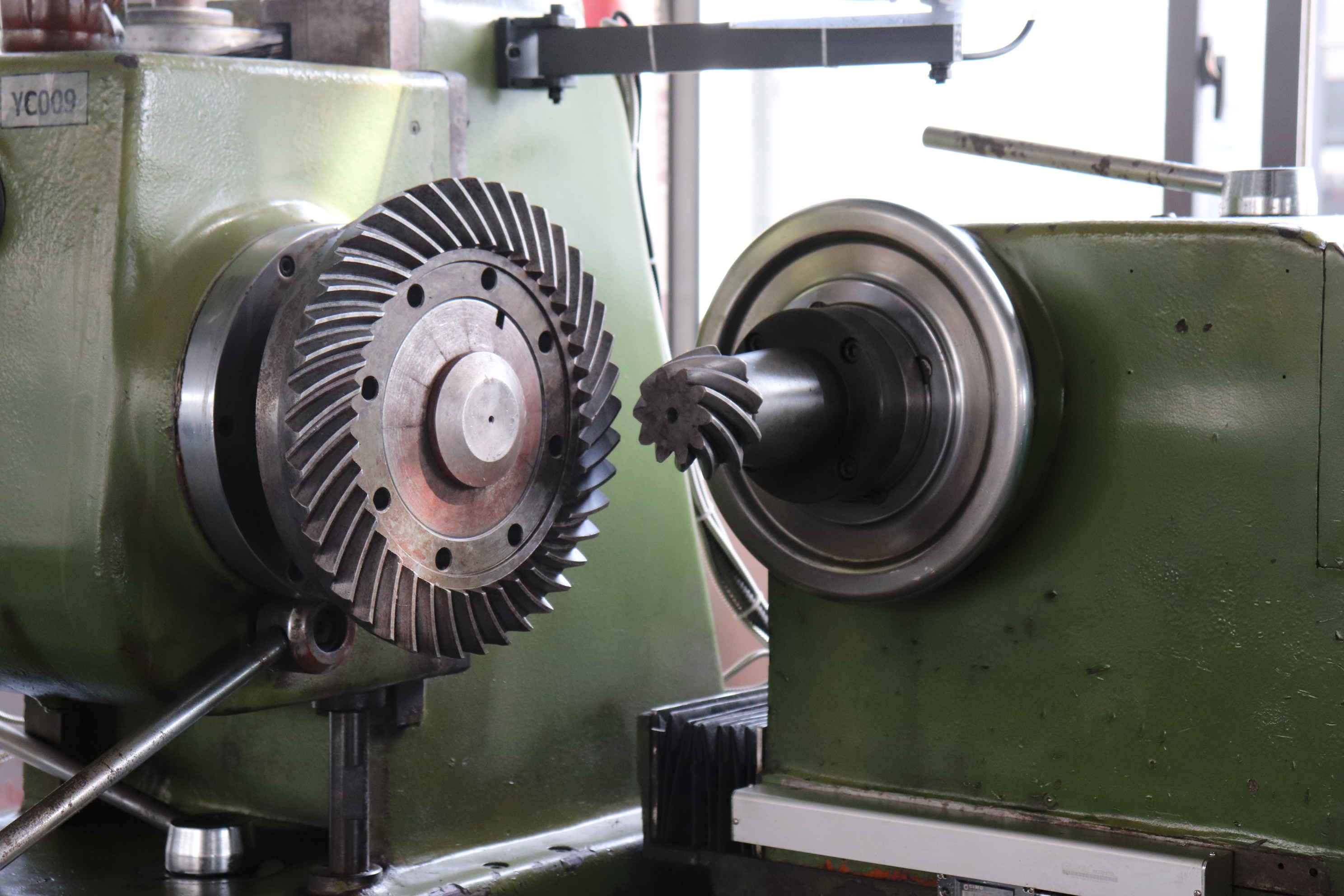

Lapping

Inspection

Packages

Our video show

Product detail pictures:

Related Product Guide:

We have been commitment to supply the competitive price ,excellent products and solutions high-quality, at the same time as fast delivery for OEM Skew Bevel Gears Used In Bevel Gear Reducer Gearbox , The product will supply to all over the world, such as: Los Angeles, Doha, Adelaide, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.