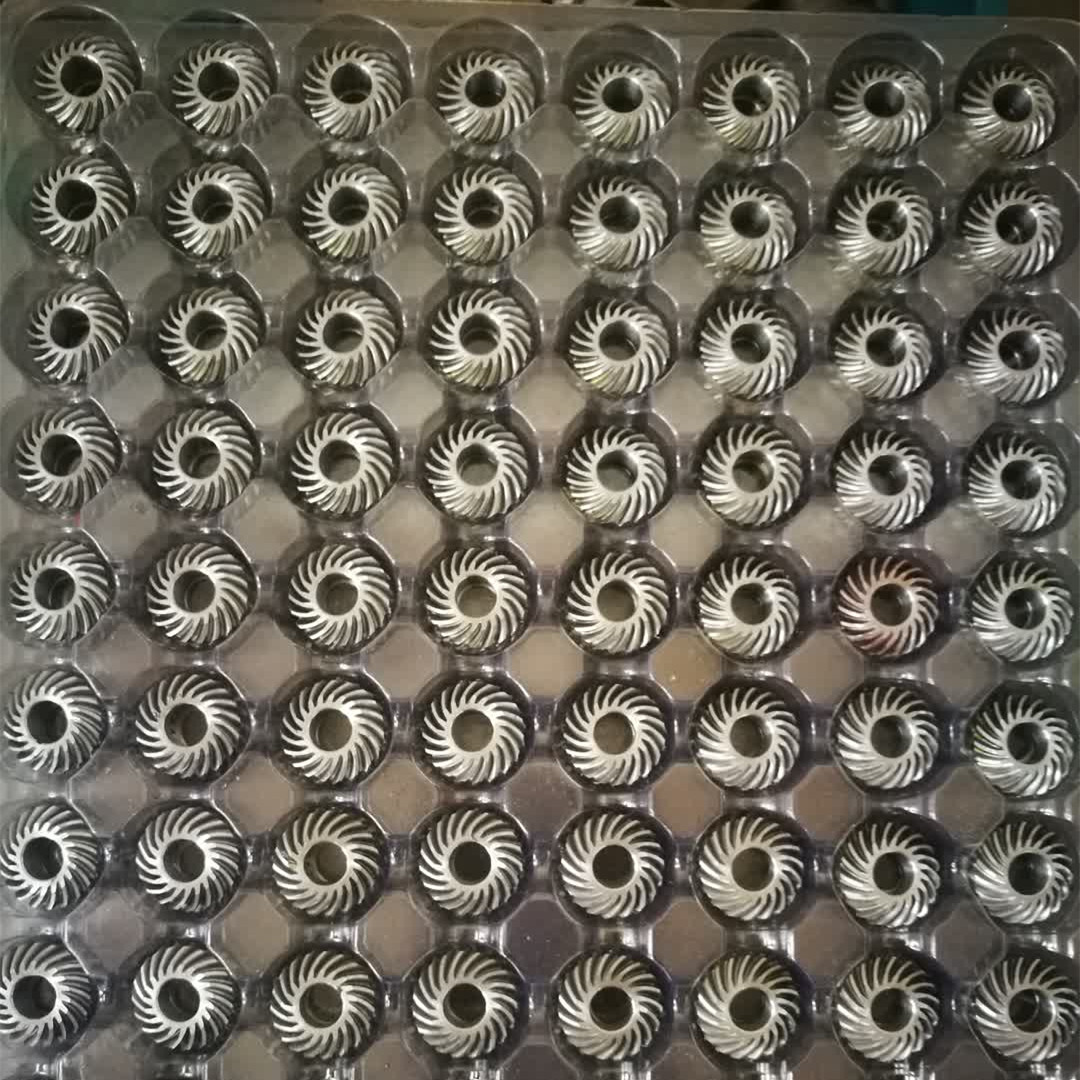

Milling gears ,The DIN6 3 5 ground helical gear set is a premium solution designed for mining applications, where reliability and efficiency are paramount. Engineered to DIN6 precision standards, these gears offer exceptional accuracy and smooth performance, reducing vibration and noise even under heavy loads. The helical design enhances power transmission efficiency while minimizing wear, making it ideal for demanding mining operations. Crafted from high-grade materials and subjected to meticulous grinding processes, these gears ensure durability and long service life. Their robust construction allows them to handle extreme conditions, such as high torque and abrasive environments commonly found in mining. With superior load capacity and precision alignment, the DIN6 3 5 ground helical gear set is the go-to choice for optimizing mining equipment, ensuring seamless operation and minimal downtime.

The production process for this set helical gear are as below :

1) Raw material

2) Forging

3) Pre-heating normalizing

4) Rough turning

5) Finish turning

6) Gear hobbing

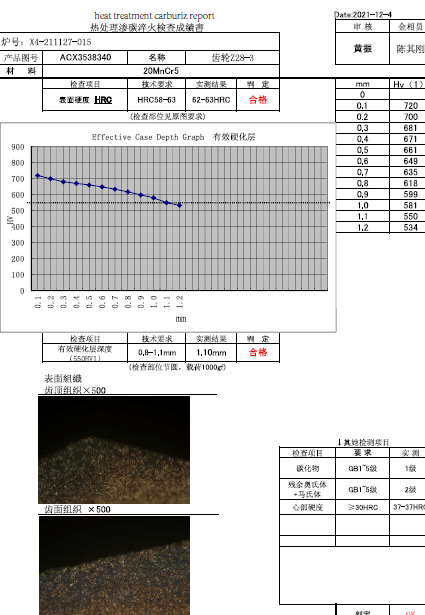

7) Heat treat carburizing 58-62HRC

8) Shot blasting

9) OD and Bore grinding

10) Gear grinding

11) Cleaning

12) Marking

13) Package and warehouse

Top ten enterprises in china ,equipped with 1200 staff ,obtained total 31 inventions and 9 patents .Advanced manufacturing equipment ,heat treat equipment ,inspection equipment .All processes from raw material to finish was done in house ,strong engineering team and quality team to meet and beyond customer’s requirement .

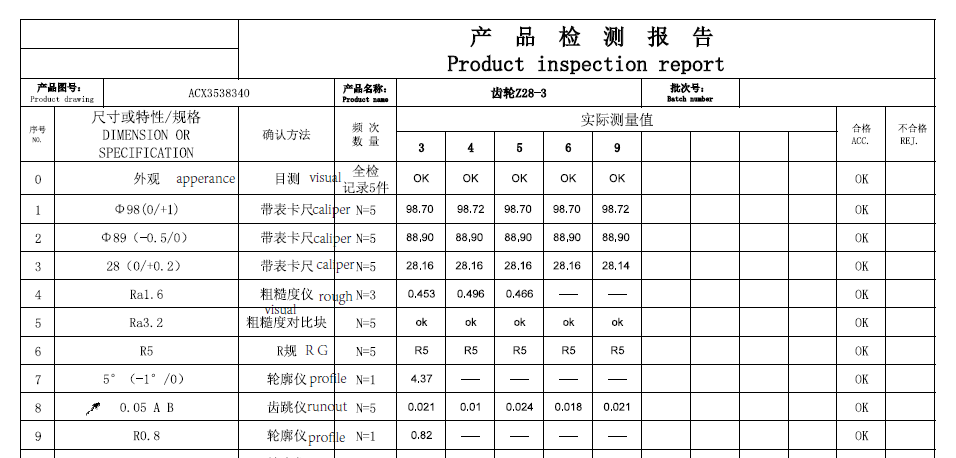

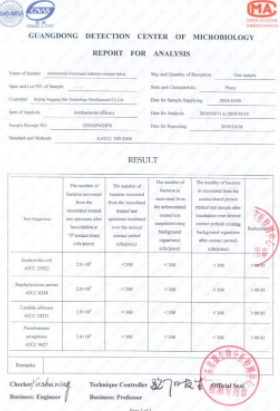

Inspection

Reports

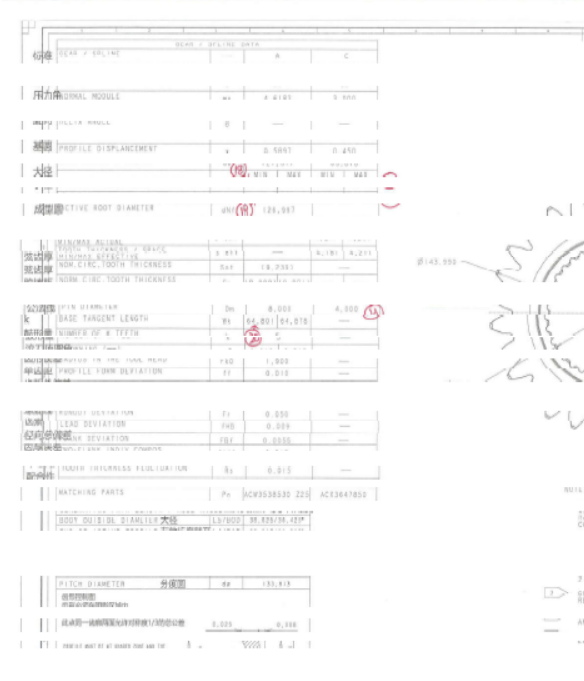

Drawing

Dimension report

Heat Treat report

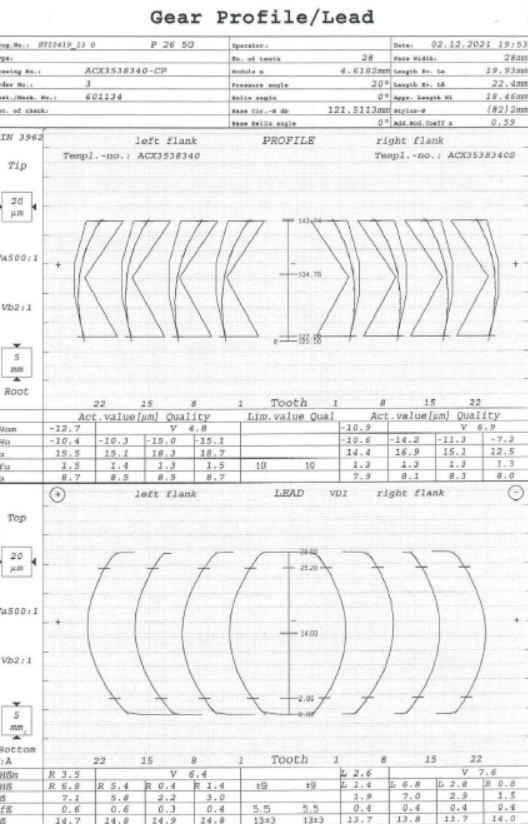

Accuracy Report

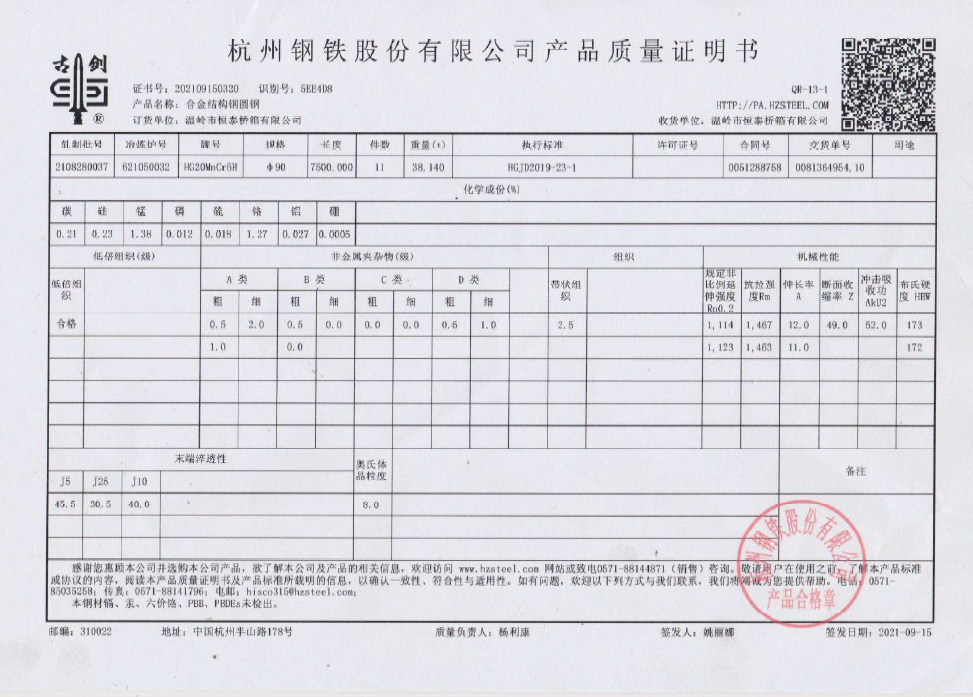

Material Report

Flaw detection report