Europe style for Grinding Bevel Gear - Gleason bevel gear for tractors – Belon Detail:

Product details

This bevel gear set was used in tractor . In the tractor , it is located in front of the driving wheel and behind the gearbox . All the transmission mechanisms and shells are called the rear axle, and its main function is to step up, increase, decelerate and change the torque .In addition to tractors with transverse engines that use cylindrical gear pairs as central transmission, most of them use bevel gear pairs, which not only increase torque and reduce speed, but also change torque transmission.

Manufacturing Plant :

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

Production Process:

Raw Material

Rough Cutting

Gear Turning

Quenching & Tempering

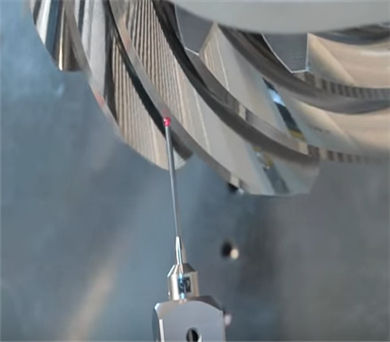

Gear Milling

Heat Treat

Gear Lapping

Testing

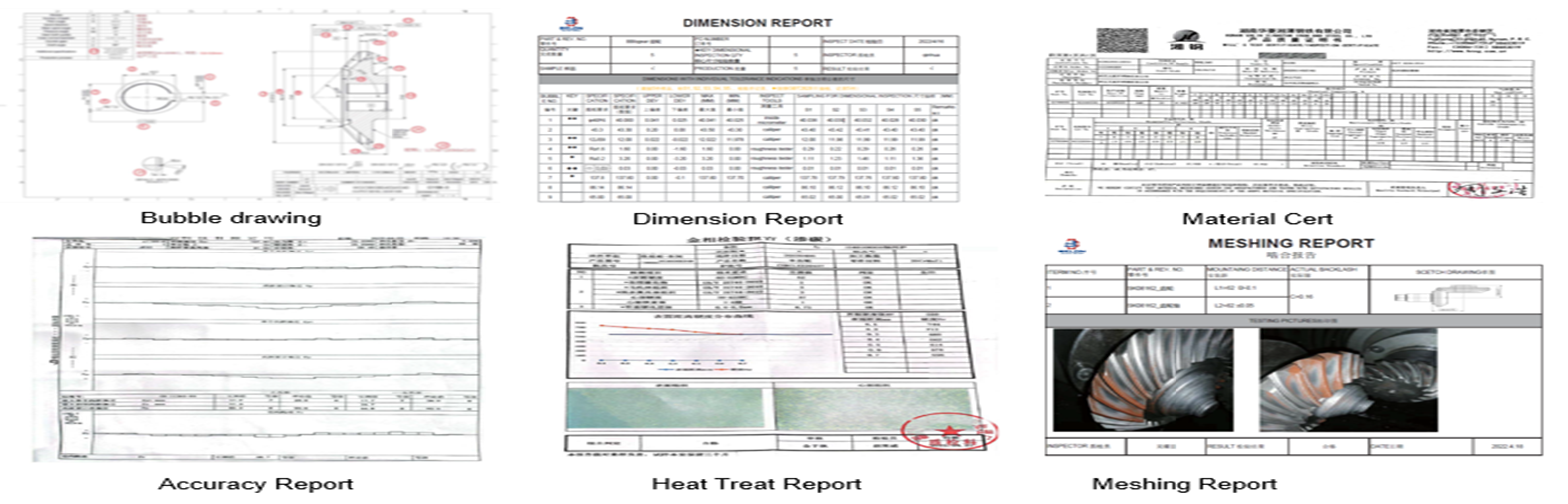

Inspection :

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Packages :

Inner package

Inner package

Carton

wooden package

Our video show

Industrial gearbox spiral bevel gear milling

Meshing test for lapping bevel gear

Surface runout testing for bevel gears

Lapping bevel gear or grinding bevel gears

Spiral bevel gears

Bevel gear broaching

Bevel gear lapping VS bevel gear grinding

Spiral bevel gear milling

Industrial robot spiral bevel gear milling method

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Europe style for Grinding Bevel Gear - Gleason bevel gear for tractors – Belon , The product will supply to all over the world, such as: Turkey, Cologne, United States, We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!