Factory For Internal Tooth Gear - ground spur gears used in cylindrical reducer – Belon Detail:

There are two main types of spur gears: external and internal. External gears have teeth cut on the outer surface of the cylinder. The two external gears mesh together and rotate in opposite directions. In contrast, internal gears have teeth cut on the inner surface of the cylinder. The external gear is inside the internal gear, and the gears rotate in the same direction. Because the gear shafts are positioned closer together, the internal gear assembly is more compact than the external gear assembly. Internal gears are mainly used for planetary gear transmission.

Spur gears are generally considered suitable for applications requiring speed reduction and torque multiplication, such as ball mills and crushing equipment. Despite the high noise levels, high-speed applications for spur gears include consumer appliances such as washing machines and blenders. Spur gears have a wide range of applications: they are used to increase or decrease the speed of an object, they can also be used to increase or decrease the torque or power of a specific object. Since spur gears transmit motion and force from one shaft to another in a mechanical structure, they are also suitable for washing machines, mixers, tumble dryers, construction machinery, fuel pumps, etc.

Manufacturing Plant :

Top ten enterprises in china ,equipped with 1200 staff ,obtained total 31 inventions and 9 patents .Advanced manufacturing equipment ,heat treat equipment ,inspection equipment .All processes from raw material to finish was done in house ,strong engineering team and quality team to meet and beyond customer’s requirement .

Production Process

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

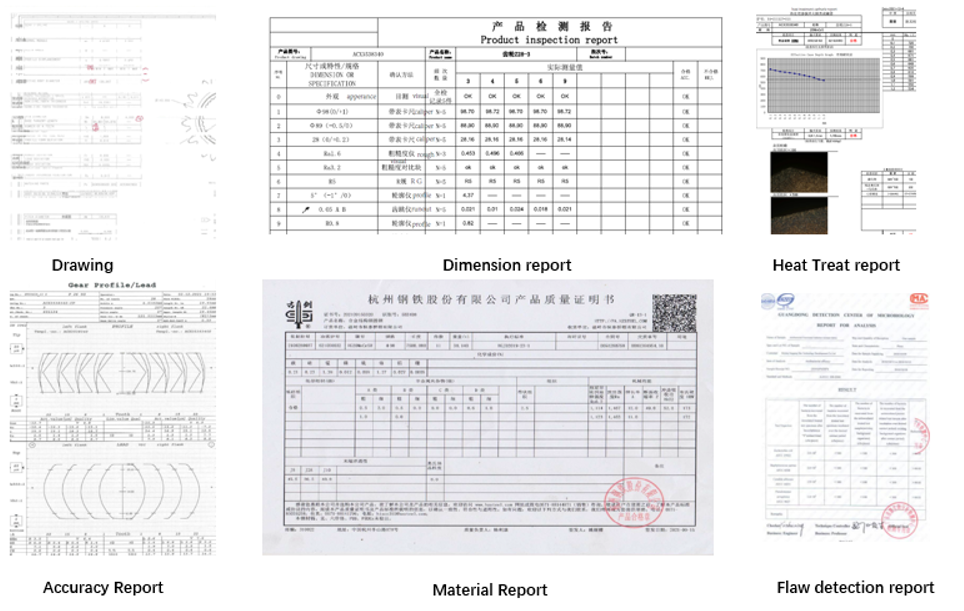

Reports

We will provide below reports also customer’s required reports before every shipping for customer to check and approve .

1).Bubble drawing

2).Dimension report

3).Material cert

4).Heat treat report

5).Accuracy report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

small helical gear motor gearshaft and helical gear

left hand or right hand helical gear hobbing

helical gear cutting on hobbing machine

helical gear shaft

single helical gear hobbing

helical gear grinding

16MnCr5 helical gearshaft & helical gear used in robotics gearboxes

worm wheel and helical gear hobbing

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating products of top quality and producing friends with people today from all around the world", we constantly place the desire of shoppers to start with for Factory For Internal Tooth Gear - ground spur gears used in cylindrical reducer – Belon , The product will supply to all over the world, such as: Berlin, Miami, belarus, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.