Factory wholesale Hypoid Gear Efficiency - Hypoid Bevel Gear Used In Medical Devices Electric Wheelchair – Belon Detail:

How to produce hypoid bevel gears ?

Two processing methods of hypoid gears

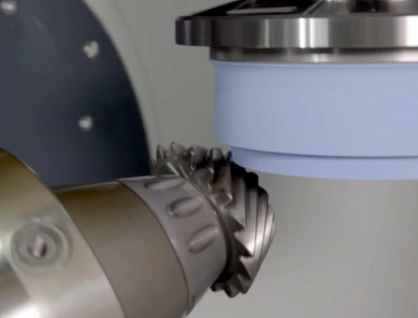

The hypoid bevel gear was introduced by Gleason Work 1925 and has been developed for many years. At present, there are many domestic equipments that can be processed, but the relatively high-precision and high-end processing is mainly made by foreign equipment Gleason and Oerlikon . In terms of finishing, there are two main gear grinding processes and lapping processes, but the requirements for the gear cutting process are different .For the gear grinding process, the gear cutting process is recommended to use face milling, and the lapping process is recommended to face hobbing .

The gears processed by the face milling type are tapered teeth, and the gears processed by the face hobbing type are equal-height teeth, that is, the tooth heights at the large and small end faces are the same.

The usual processing process is roughly machining after pre-heating, and then finishing machining after heat treat. For the face hobbing type, it needs to be lapped and matched after heating. Generally speaking, the pair of gears ground together should still be matched when assembled later. However, in theory, gears with gear grinding technology can be used without matching. However, in actual operation, considering the influence of assembly errors and system deformation, the matching mode is still used.

Manufacturing Plant

China the first one to import USA UMAC technology for hypoid gears .

Production Process

Raw Material

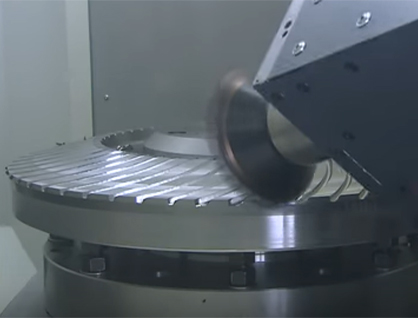

Rough Cutting

Turning

Quenching And Tempering

Gear Milling

Heat Treat

Gear Grinding

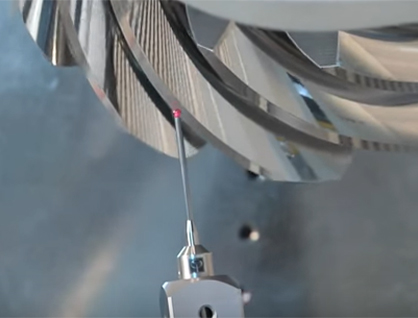

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

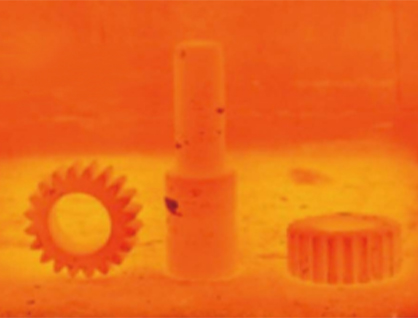

Hypoid Gears

Km Series Hypoid Gears For Hypoid Gearbox

Hypoid Bevel Gear In Industrial Robot Arm

Hypoid Bevel Gear Milling & Mating Testing

Hypoid Gear Set Used In Mountain Bike

Product detail pictures:

Related Product Guide:

Our products and solutions are greatly recognized and trustworthy by customers and may fulfill constantly changing financial and social requires for Factory wholesale Hypoid Gear Efficiency - Hypoid Bevel Gear Used In Medical Devices Electric Wheelchair – Belon , The product will supply to all over the world, such as: Iran, Mauritius, Orlando, With top quality products, great after-sales service and warranty policy, we win trust from many overseas partner, many good feedbacks witnessed our factory's growth. With full confidence and strength, welcome customers to contact and visit us for future relationship.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.