The worm gear shaft is widely used in various industries gearbox due to its ability to provide high torque, smooth motion, and self locking capabilities. One of its primary applications is in speed reduction systems, where it helps achieve significant speed control while maintaining power efficiency. This makes it ideal for machinery requiring precise movement, such as conveyor belts, elevators, and lifting equipment.

In the automotive industry, worm gear shafts are used in steering mechanisms, ensuring smooth and controlled movement of vehicles. They are also found in winches and hoists, providing stability and preventing back-driving, which enhances safety.

In industrial machinery, worm gear shafts play a key role in mixers, presses, and automation equipment, where controlled motion and high torque transmission are essential. They are also used in textile machines, medical equipment, and robotics, enabling precise motion and load handling.

Additionally, worm gear shafts are found in household appliances, such as electric motors, garage door openers, and even musical instrument tuning systems. Their durability, quiet operation, and efficiency make them an indispensable component in modern mechanical application

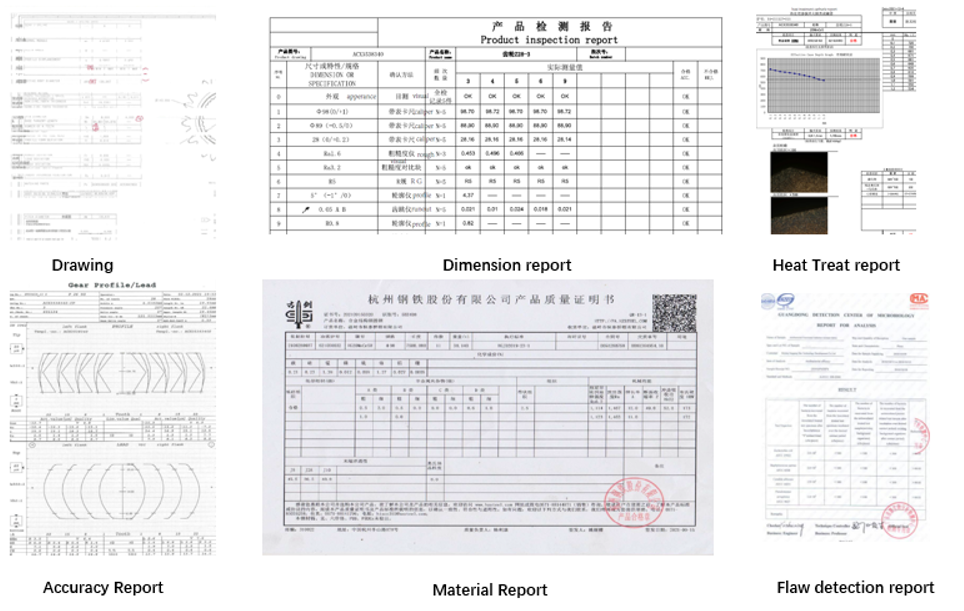

Inspection

Reports