We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for Good Quality Custom Cast Steel Cylindrical Gear / Bevel Gear / Turbine for Bus, With outstanding services and good quality, and an business of foreign trade showcasing validity and competitiveness, which will be reliable and welcomed by its purchasers and makes happiness to its workers.

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for Sprocket and Worm Gear, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!

In an era of interconnected technologies, we understand the importance of connectivity and smart functionality. Our gear systems are designed with compatibility in mind, seamlessly integrating with digital monitoring and control systems. This connectivity not only enhances ease of use but also facilitates predictive maintenance, reducing downtime and enhancing overall system efficiency.

As part of our commitment to quality control, we implement rigorous testing procedures throughout the manufacturing process. This guarantees that each gear system leaving our facilities adheres to the highest standards, contributing to a reputation for reliability and consistency.

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

1) Bubble drawing

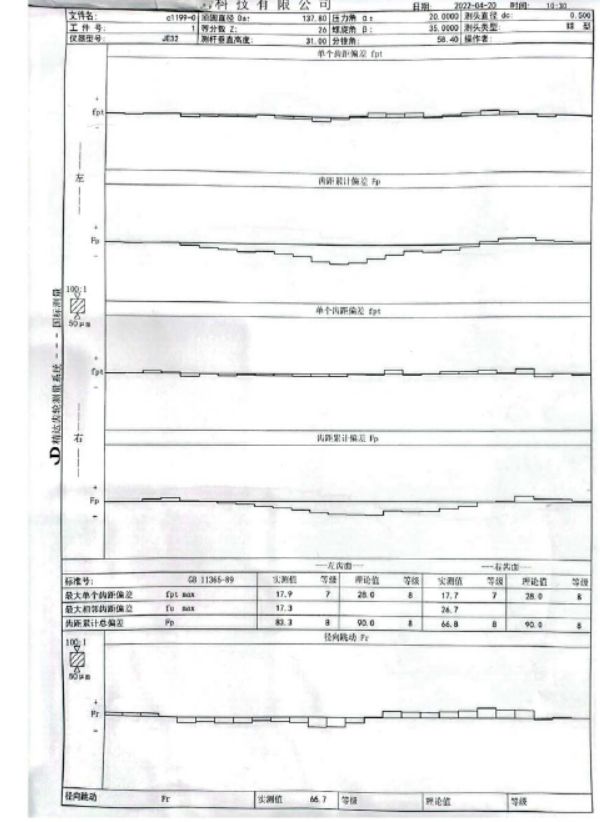

2) Dimension report

3) Material cert

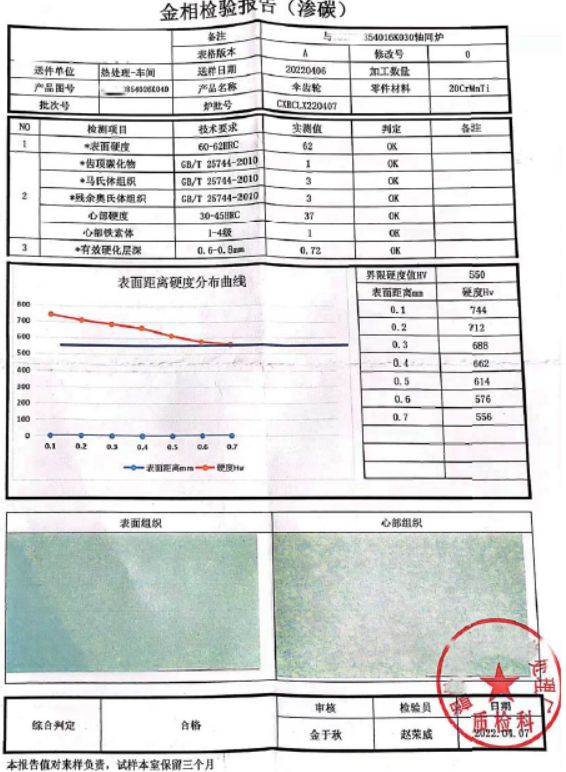

4) Heat treat report

5) Ultrasonic Test report (UT)

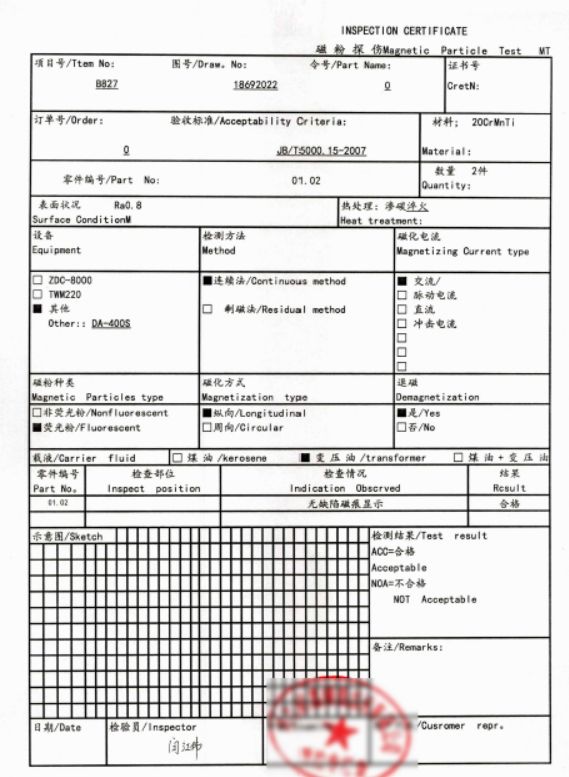

6) Magnetic Particle Test report (MT)

Meshing test report

Manufacturing Plant

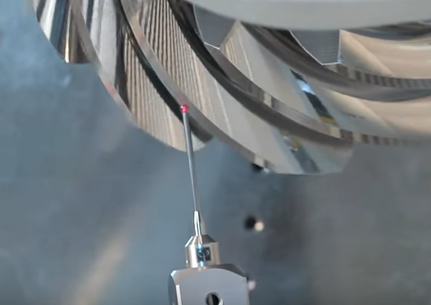

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

Production Process

raw material

rough cutting

turning

quenching and tempering

gear milling

Heat treat

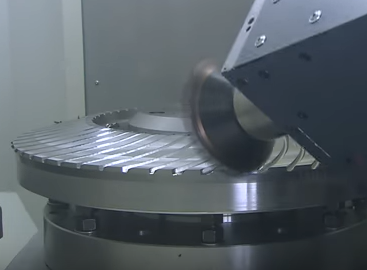

gear grinding

testing

Inspection

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

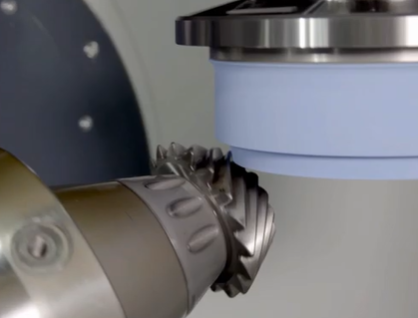

big bevel gears meshing

ground bevel gears for industrial gearbox

spiral bevel gear grinding / china gear supplier support you to speed up delivery

Industrial gearbox spiral bevel gear milling

meshing test for lapping bevel gear

lapping bevel gear or grinding bevel gears

Bevel gear lapping VS bevel gear grinding

spiral bevel gear milling

surface runout testing for bevel gears

spiral bevel gears

bevel gear broaching

industrial robot spiral bevel gear milling method

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for 2025 Good Quality Custom Cast Steel Cylindrical Gear / Bevel Gear / Turbine for Bus, With outstanding services and good quality, and an business of foreign trade showcasing validity and competitiveness, which will be reliable and welcomed by its purchasers and makes happiness to its workers.

2019 Good Quality Sprocket and Worm Gear, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!