OEM/ODM kinds of High quality precision machinery geras,There are two main types of spur gears external gear and internal gear . External gears have teeth cut on the outer surface of the cylinder gear. The two external gears mesh together and rotate in opposite directions. In contrast, internal gears have teeth cut on the inner surface of the cylinder gear. The external gear is inside the internal gear, and the gears rotate in the same direction. Because the gear shafts are positioned closer together, the internal gear assembly is more compact than the external gear assembly. Internal gears are mainly used for planetary gear transmission.

Spur gears are generally considered suitable for applications requiring speed reduction and torque multiplication, such as ball mills and crushing equipment. Despite the high noise levels, high-speed applications for spur gears include consumer appliances such as washing machines and blenders. Spur gears have a wide range of applications: they are used to increase or decrease the speed of an object, they can also be used to increase or decrease the torque or power of a specific object. Since spur gears transmit motion and force from one shaft to another in a mechanical structure, they are also suitable for washing machines, mixers, tumble dryers, construction machinery, fuel pumps, etc.

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .

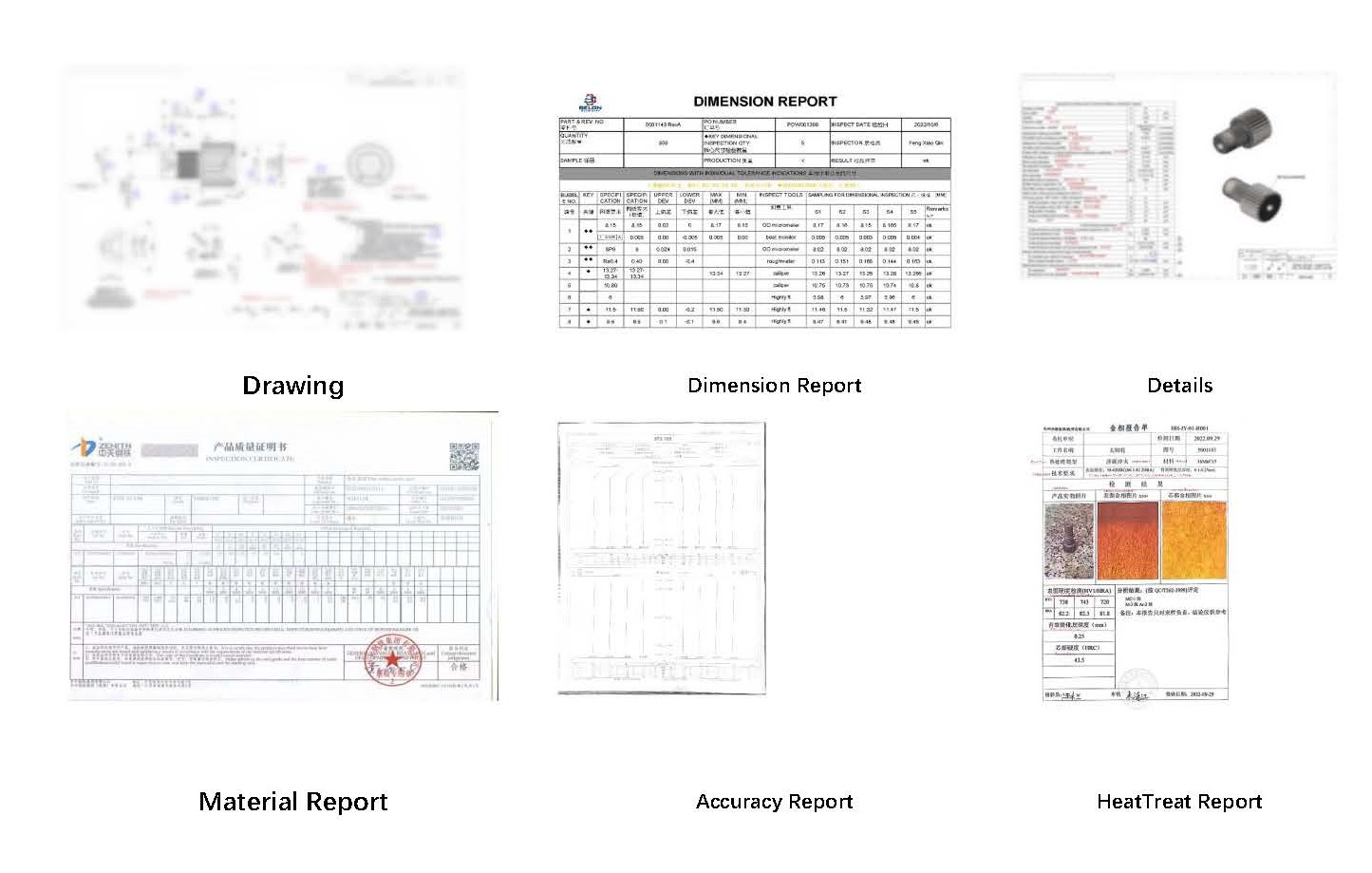

Reports

1).Bubble drawing

2).Dimension report

3).Material cert

4).Heat treat report

5).Accuracy report