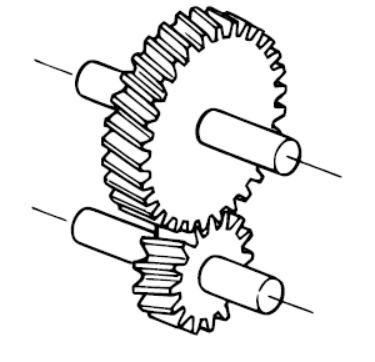

The teeth are twisted oblique to the gear axis. The hand of helix is designated as either left or right. Right hand helical gears and left hand helical gears mate as a set, but they must hae the same helix angle ,

Helical Gears: Precision and Efficiency

Discover the latest innovation in mechanical power transmission with our new line of Helical Gears. Designed for optimal performance in demanding applications, helical gears feature angled teeth that mesh smoothly and quietly, reducing noise and vibration compared to traditional spur gears.

Ideal for high-speed and heavy-load operations, our helical gears offer superior torque transmission and increased efficiency, making them essential for industries such as automotive, aerospace, and manufacturing. They excel in applications requiring precise motion control and minimal backlash.

Engineered with high-quality materials and advanced manufacturing techniques, our helical gears ensure reliability and durability in diverse environments. Whether you're enhancing existing machinery or developing new systems, our helical gears provide the robust solution you need for reliable performance and extended service life.