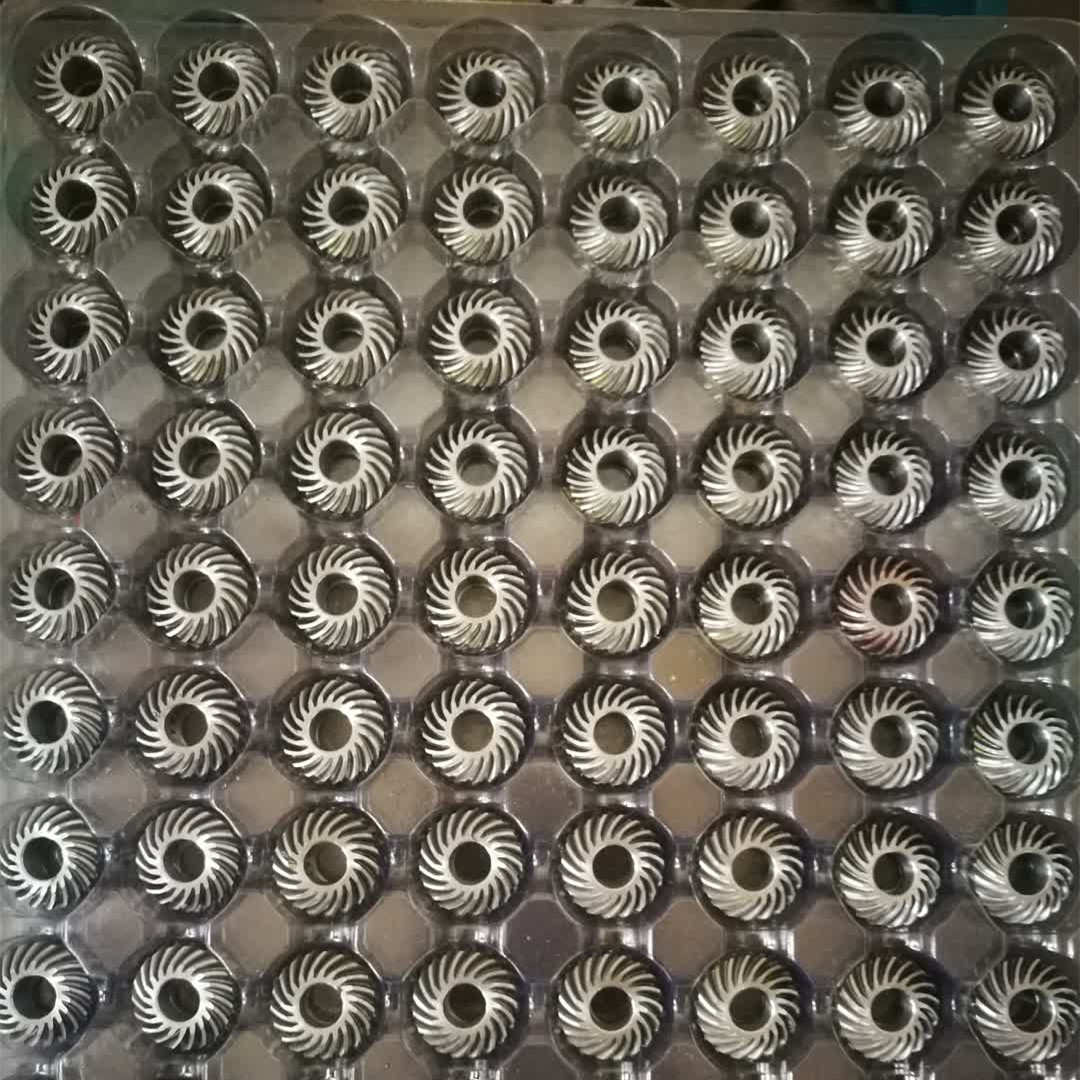

In helical gearboxes, these gears are arranged to transmit power efficiently between parallel or non-parallel shafts. This versatility makes them a preferred choice in industries like manufacturing, automotive, and power generation. The angled teeth allow for higher torque transmission compared to spur gears of the same size, making them suitable for demanding applications.

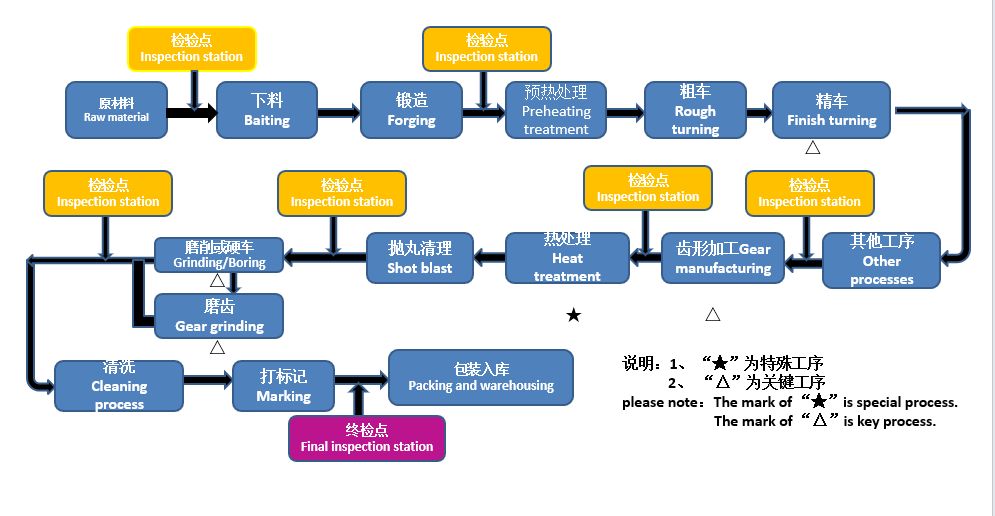

How to control the process quality and when to do the process inspection process ? This chart is clear to view .The important process for cylindrical gears .Which reports should be created during each process ?

Here is the whole production process for this helical gear

1) Raw material 8620H or 16MnCr5

1) Forging

2) Pre-heating normalizing

3) Rough turning

4) Finish turning

5) Gear hobbing

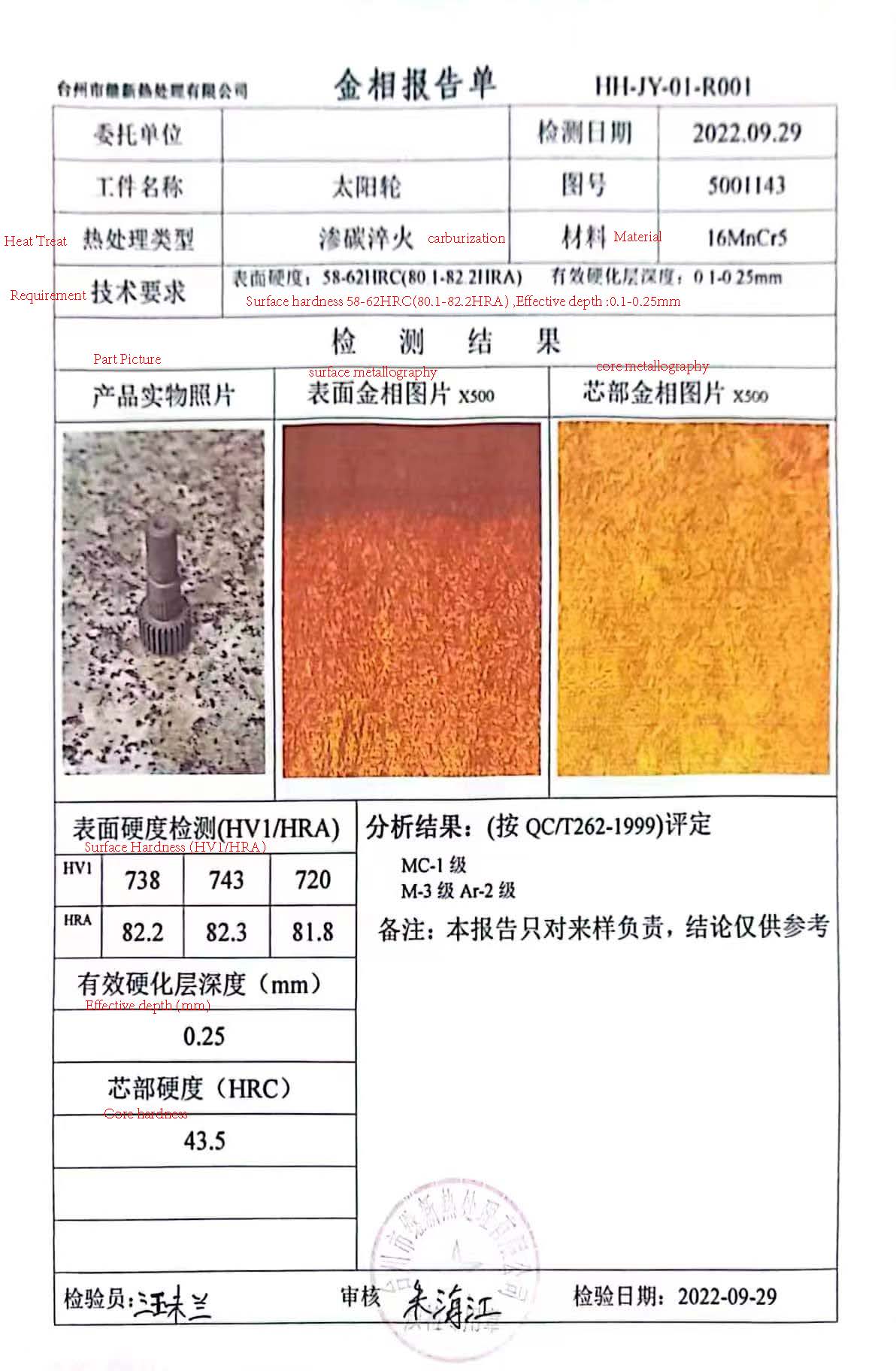

6) Heat treat carburizing 58-62HRC

7) Shot blasting

8) OD and Bore grinding

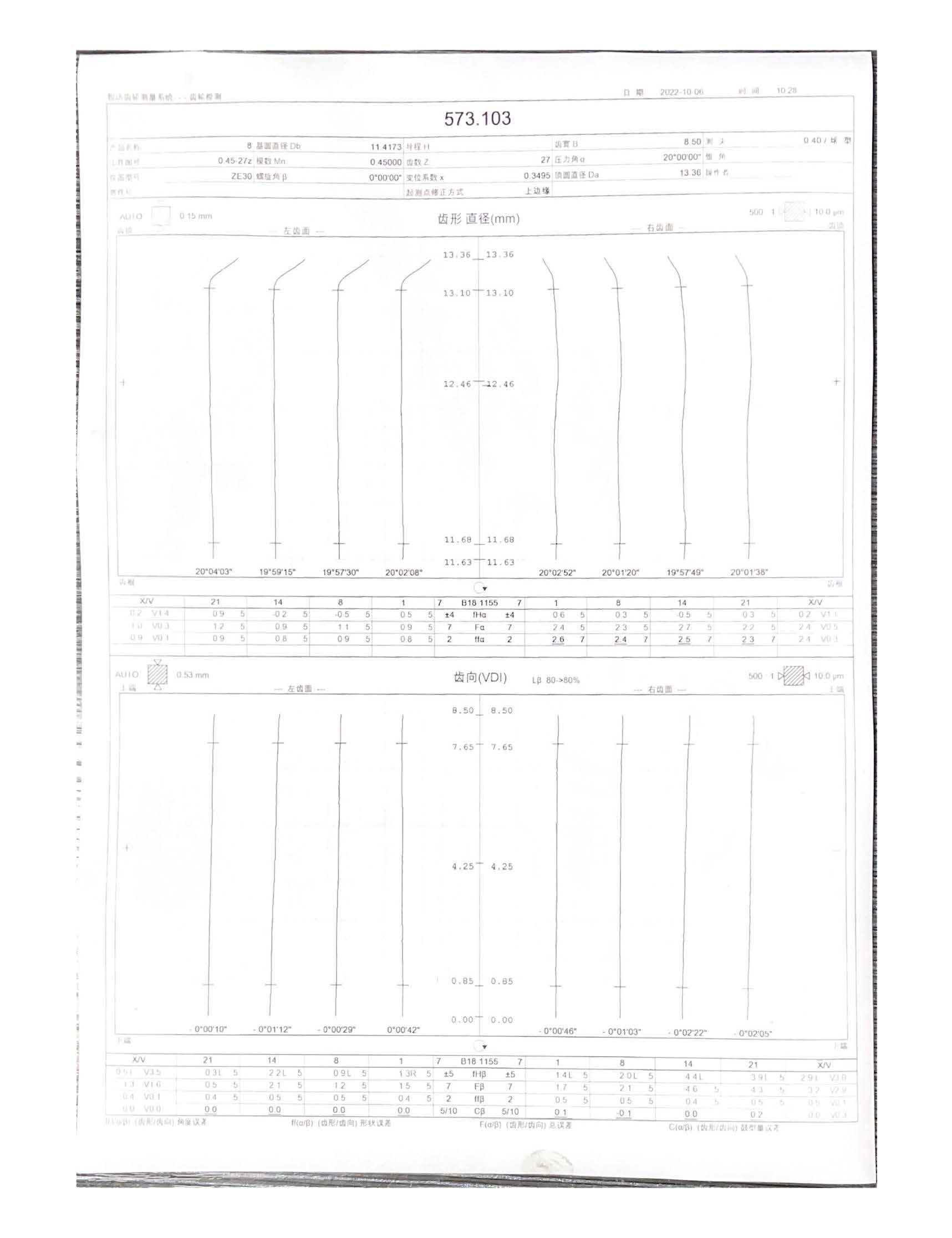

9) Helical gear grinding

10) Cleaning

11) Marking

12) Package and warehouse

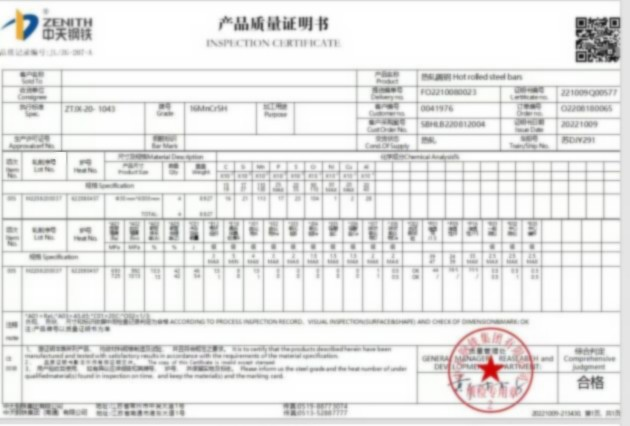

We will provide full quality files before shipping for customer’s view and approval .

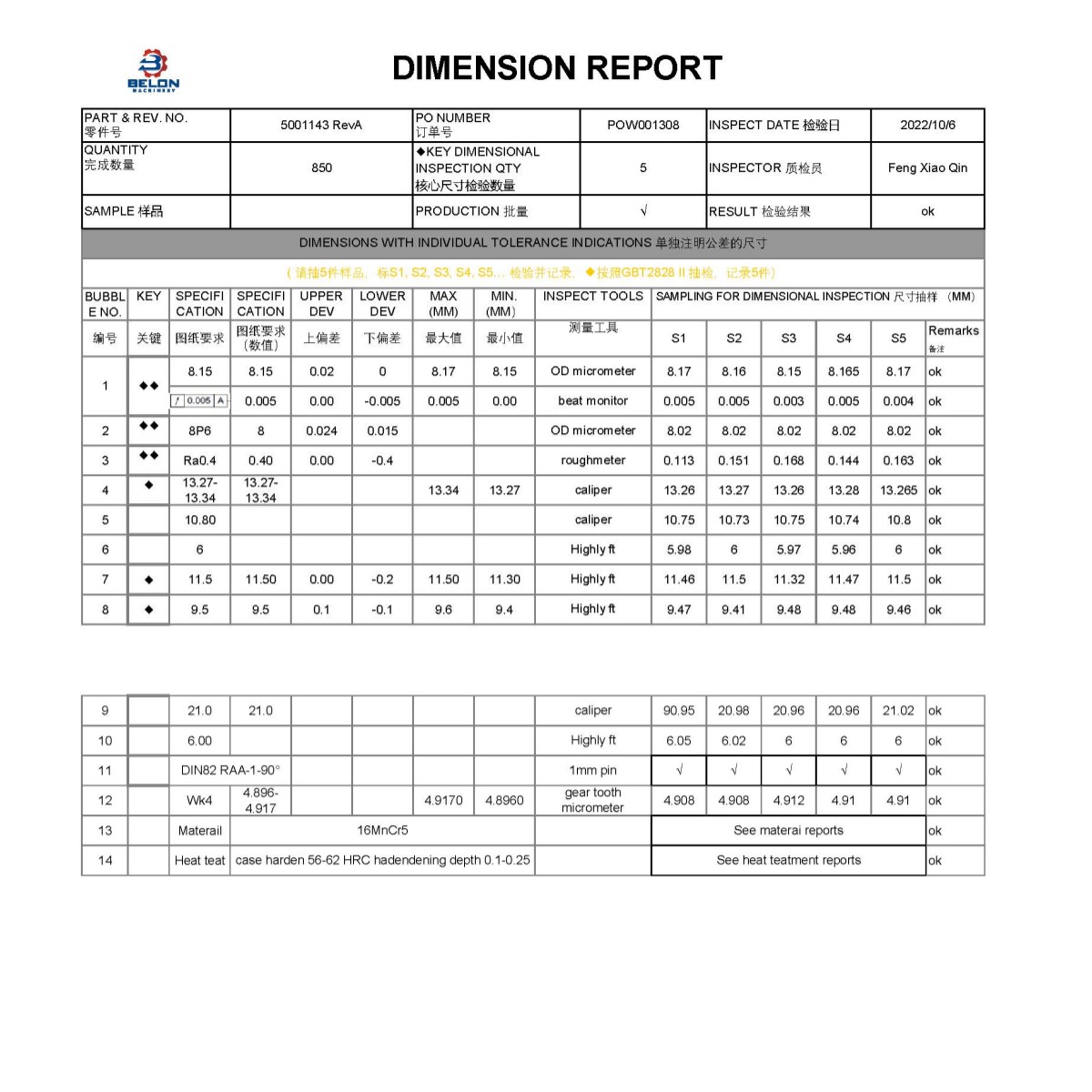

1)Bubble drawing

2)Dimension report

3)Material cert

4)Heat treat report

5)Accuracy report

6)Part pictures ,videos

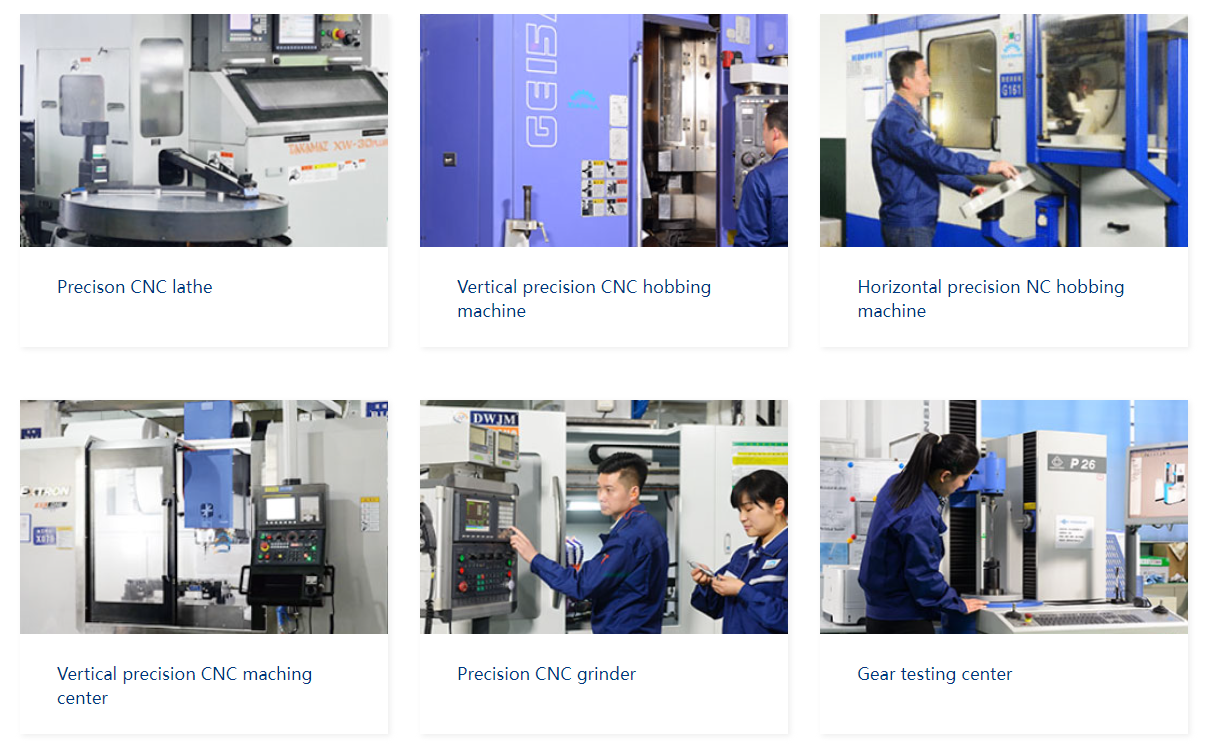

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

forging

grinding

hard turning

heat treatment

hobbing

quenching & tempering

soft turning

testing

Inspection

We equipped with advanced inspection equipment like Brown & Sharpe three-coordinate measuring machine , Colin Begg P100/P65/P26 measurement center, German Marl cylindricity instrument , Japan roughness tester , Optical Profiler , projector , length measuring machine etc. to make sure the final inspection accurately and completely .