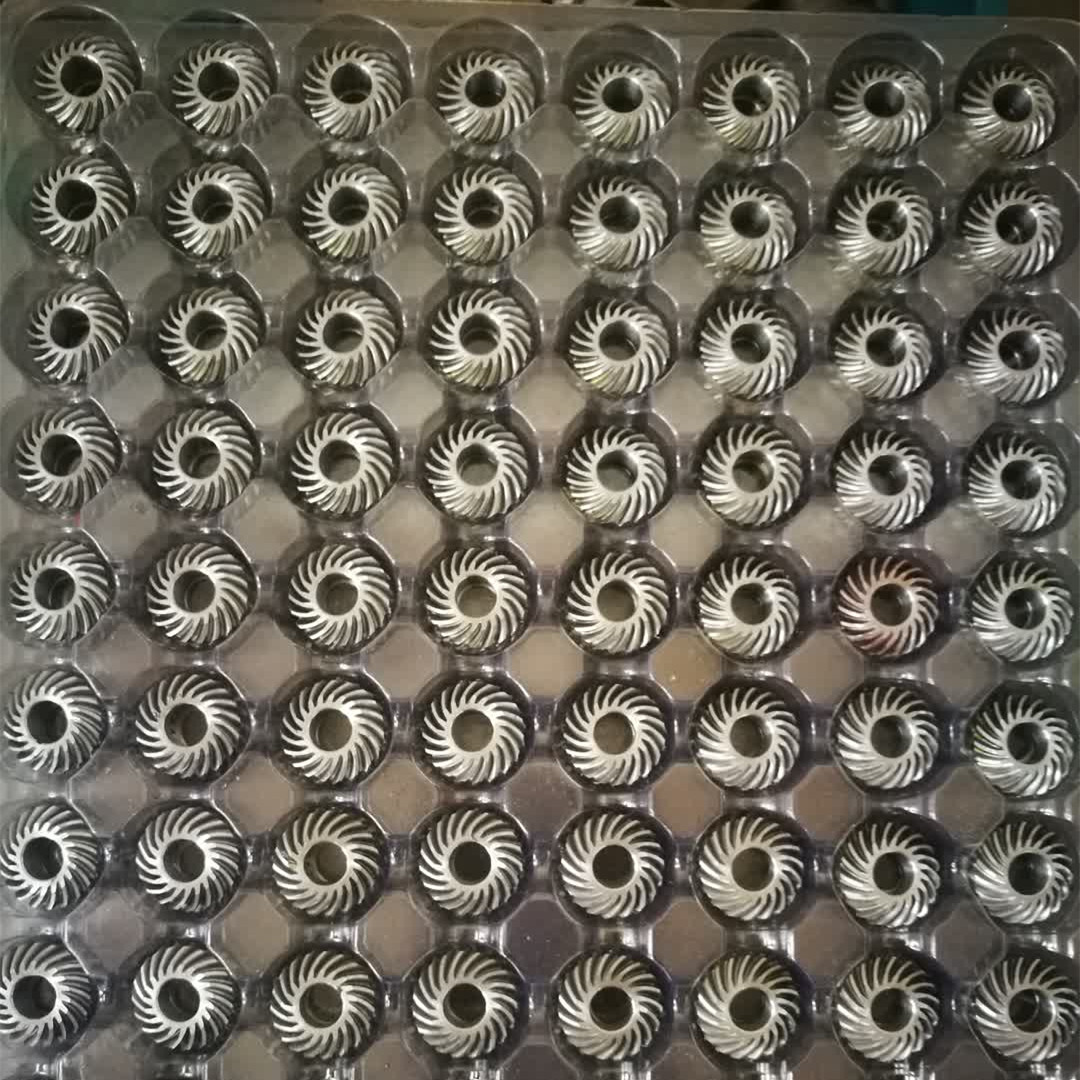

Our high accuracy helical gear shafts are specifically designed for planetary gear reducers, ensuring superior performance and reliability. Crafted with precision engineering, these gear shafts provide smooth power transmission, reduced noise, and enhanced load capacity.

The helical gear design allows for gradual tooth engagement, minimizing wear and ensuring longer service life, even under high torque applications. Manufactured from premium materials and subjected to strict quality control, our gear shafts deliver exceptional durability and efficiency.

Ideal for use in robotics, industrial automation, and heavy machinery, our helical gear shafts are tailored to meet the demanding requirements of modern planetary gear systems. Experience optimal performance and precision with our expertly engineered solutions.

1) Raw material

2) Forging

3) Pre-heating normalizing

4) Rough turning

5) Finish turning

6) Hobbing the teeth

7) Heat treat carburizing 57-62HRC

8) Shot blasting

9) OD and Bore grinding

10) Helical gear grinding

11) Cleaning

12) Marking

13) Package and warehouse

Shanghai Belon Machinery Co.,Ltd has been focusing on high precision OEM gears ,shafts and solutions for the Agriculture ,Automotive, Mining , Aviation ,Construction ,Oil and Gas ,Robotics , Automation and Motion control etc. industries .lBelon Gear holds the slogan "Belon Gear to make gears be longer"We have been striving to optimize the gears design and manufacturing methods to maximum achieve or beyond customer's expectation to decrease gears noise and increase gears life

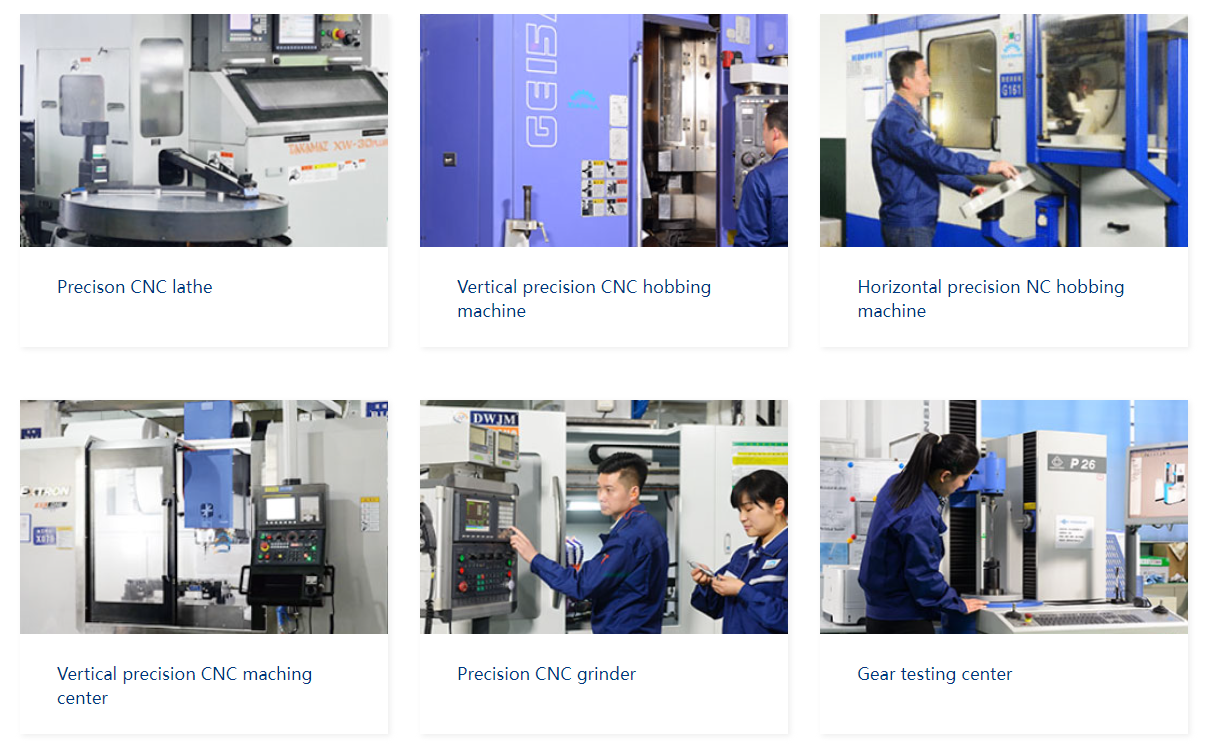

Top ten enterprises in china ,equipped with 1200 staff ,obtained total 31 inventions and 9 patents .Advanced manufacturing equipment ,heat treat equipment ,inspection equipment .All processes from raw material to finish was done in house ,strong engineering team and quality team to meet and beyond customer’s requirement .

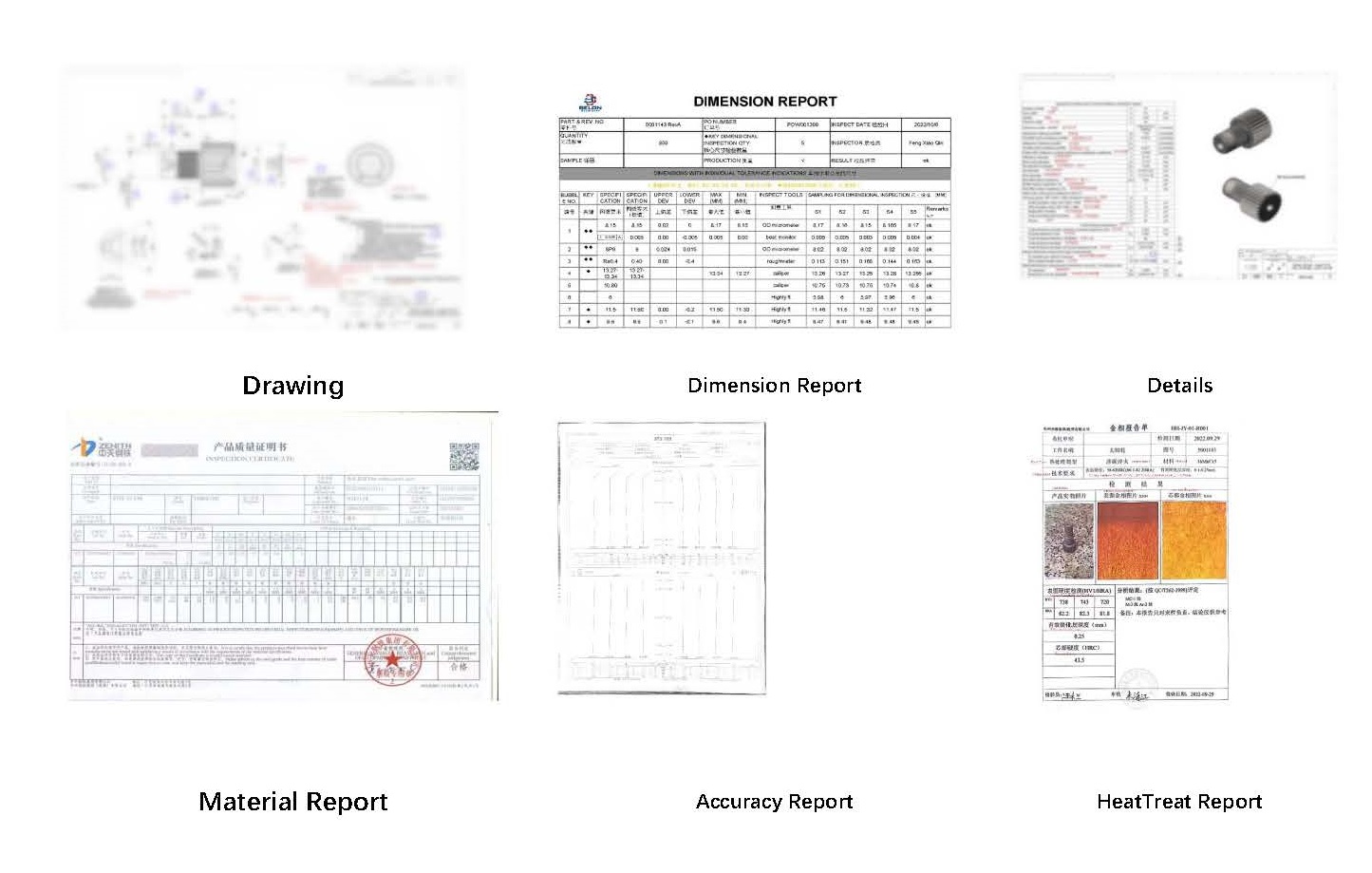

Inspection

Reports