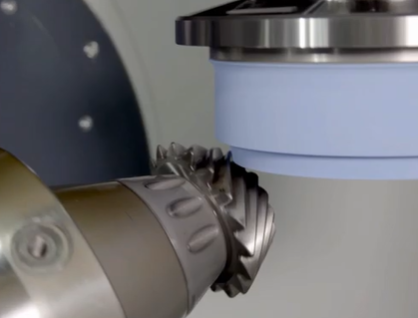

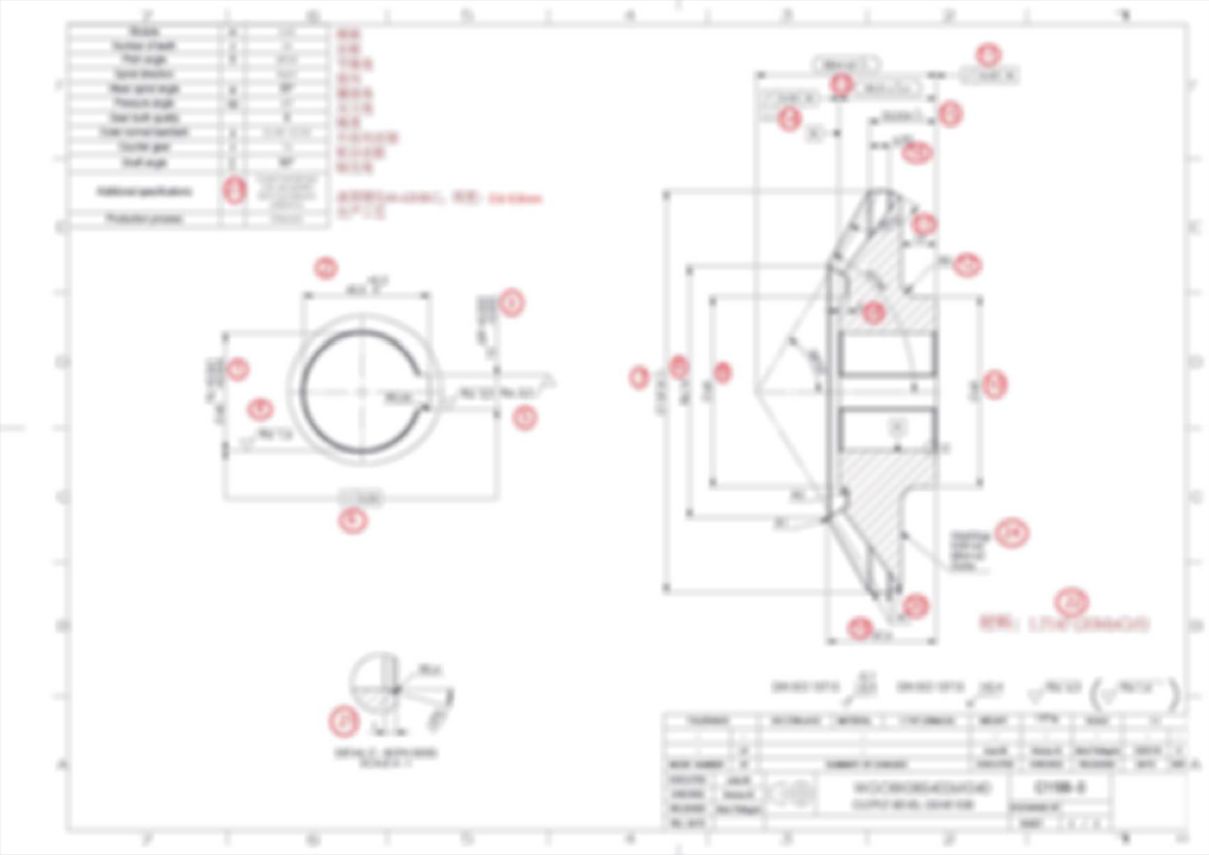

Applications of Left Spiral Bevel Gear Sets in Various Industries

Left spiral bevel gear sets are renowned for their excellent mechanical properties, making them essential components in various industries. Their unique design and efficient performance allow them to transmit power between intersecting axes at different angles, offering reliability in demanding applications. Below are some key areas where left spiral bevel gears are widely used:

Automotive Industry:

In the automotive sector, left spiral bevel gears are critical in rear wheel drive systems, where they transfer power from the engine to the rear wheels. They are also used in all wheel drive systems to enhance torque distribution between front and rear axles. The majority of these gears in passenger cars use ground teeth to achieve higher precision and smoothness in operation.

Railway Systems:

Left spiral bevel gears are integral to railway drive systems, particularly in electric and diesel-powered locomotives. They transmit power from the engine to the axles, allowing for smooth and reliable operation. Their strength and durability ensure they can handle the heavy loads and long-distance travel typical in railway applications.

Construction Machinery:

In the construction industry, left spiral bevel gears are found in heavy-duty machinery, including cranes and excavators. These gears are used in hydraulic power systems to drive auxiliary components such as winches and lifting arms. They are often manufactured through milling or grinding processes and require minimal post-heat-treatment finishing.

Aviation:

In aviation, left spiral bevel gear are essential in jet engines and helicopter systems. In jet aircraft, these gears transmit auxiliary motion and power between different components of the engine. Helicopters utilize multiple sets of bevel gears, including hypoid gears, to manage the transmission of power at non-right angles, crucial for rotor control and stability.

Industrial Gearboxes:

Industrial gearboxes using left spiral bevel gears are common across various manufacturing and processing industries. These gearboxes are primarily employed to change rotational speed and direction in machinery. The gears in these systems can vary significantly in size, with ring diameters ranging from under 50mm to over 2000mm. After heat treatment, gears are often finished by scraping or grinding to ensure precision and performance.

Marine Applications:

Left spiral bevel gears play a crucial role in marine propulsion systems, such as in outboard engines and larger ocean going vessels. They are used in stern drives to adjust the propeller’s angle, allowing for efficient propulsion and maneuverability. By transmitting power from the engine to the propeller shaft, these gears ensure smooth operation even under challenging marine conditions.

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

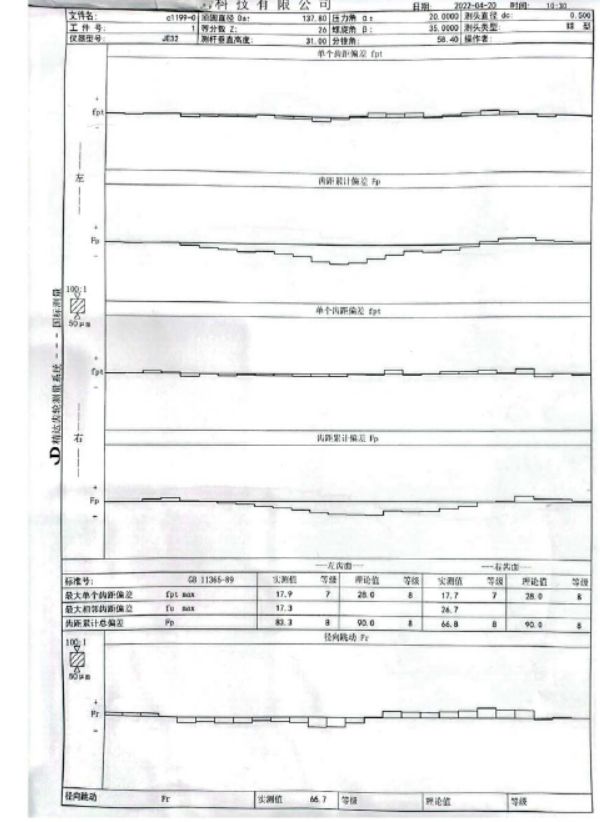

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

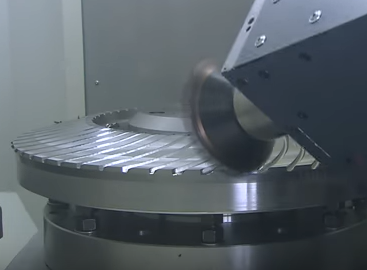

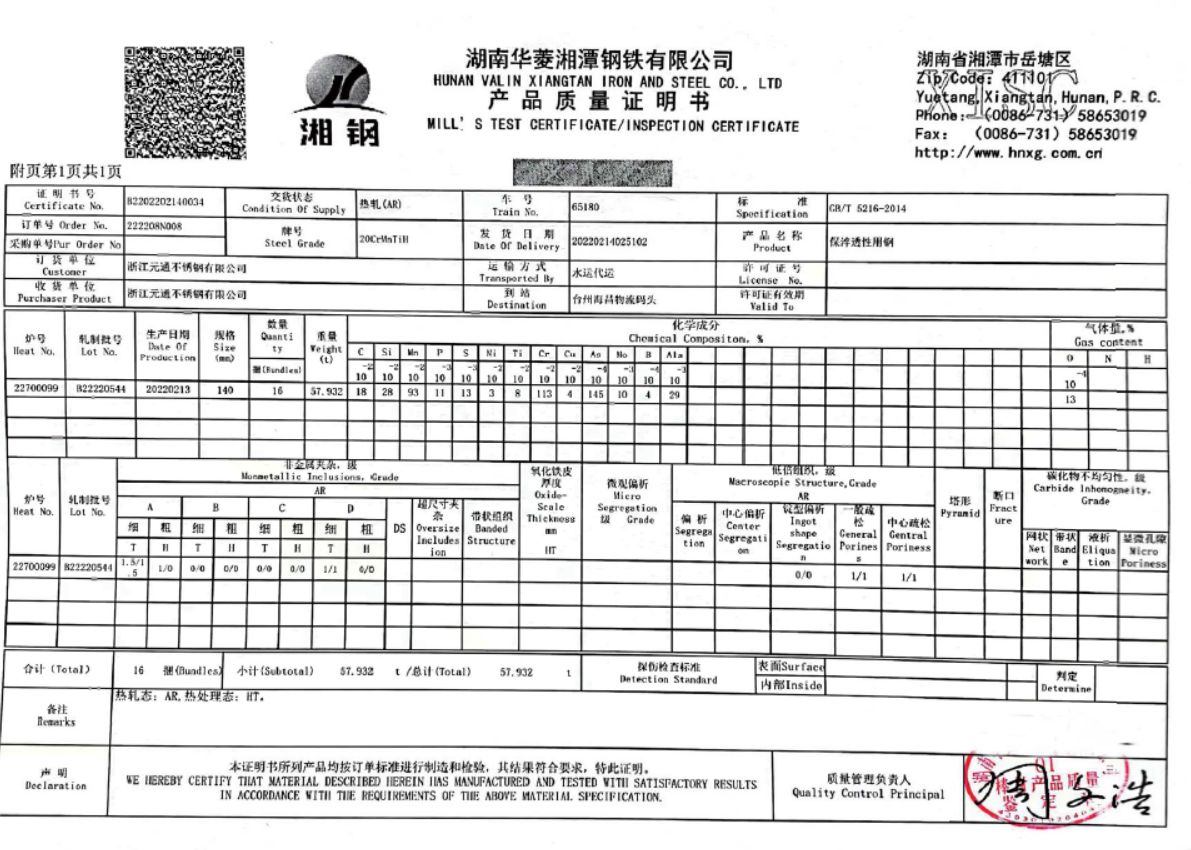

raw material

rough cutting

turning

quenching and tempering

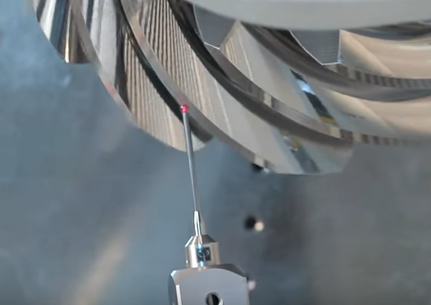

gear milling

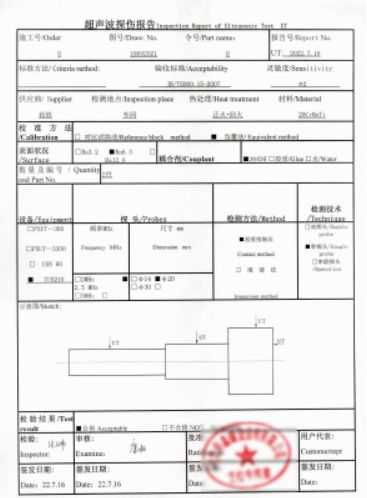

Heat treat

gear milling

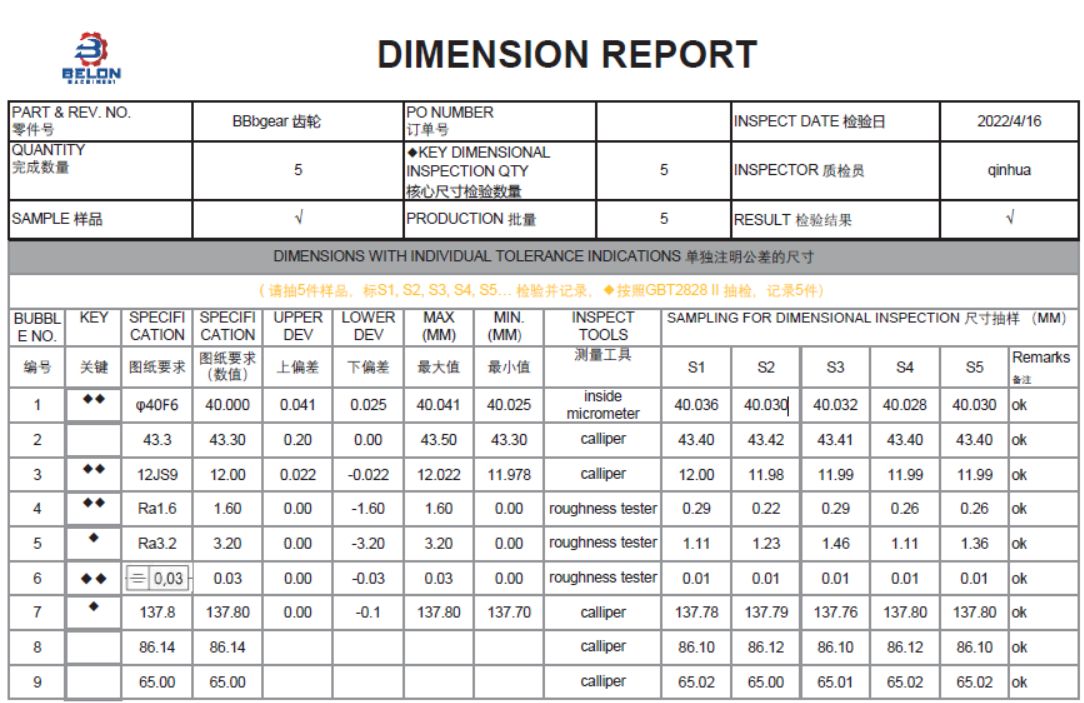

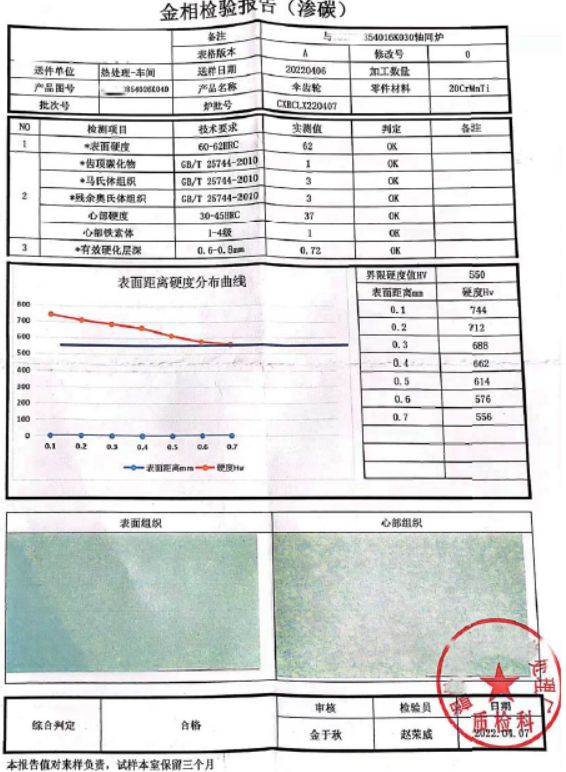

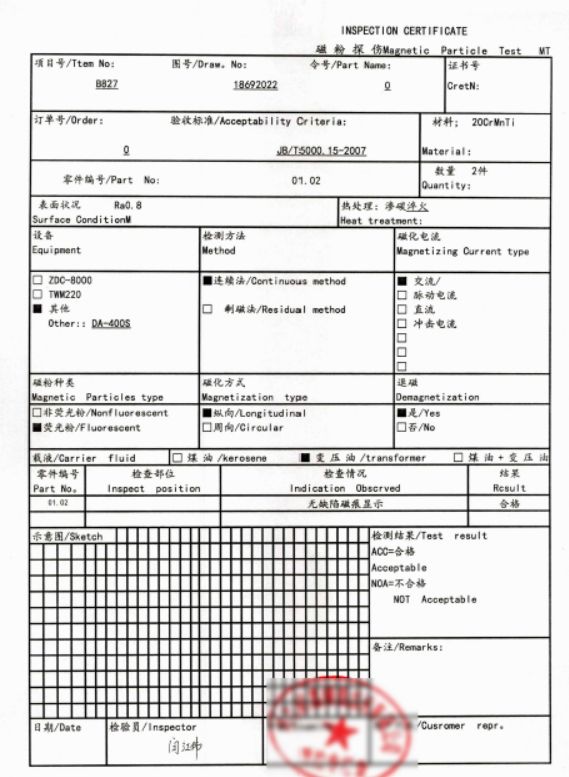

testing