Introducing our revolutionary High-Performance motorcycle bevel gear a pinnacle of engineering excellence that transcends the ordinary to elevate your riding experience to unprecedented heights. Each aspect of this meticulously crafted gear has been meticulously fine-tuned to perfection, delivering unrivaled precision and durability that sets it apart from anything else in the market.

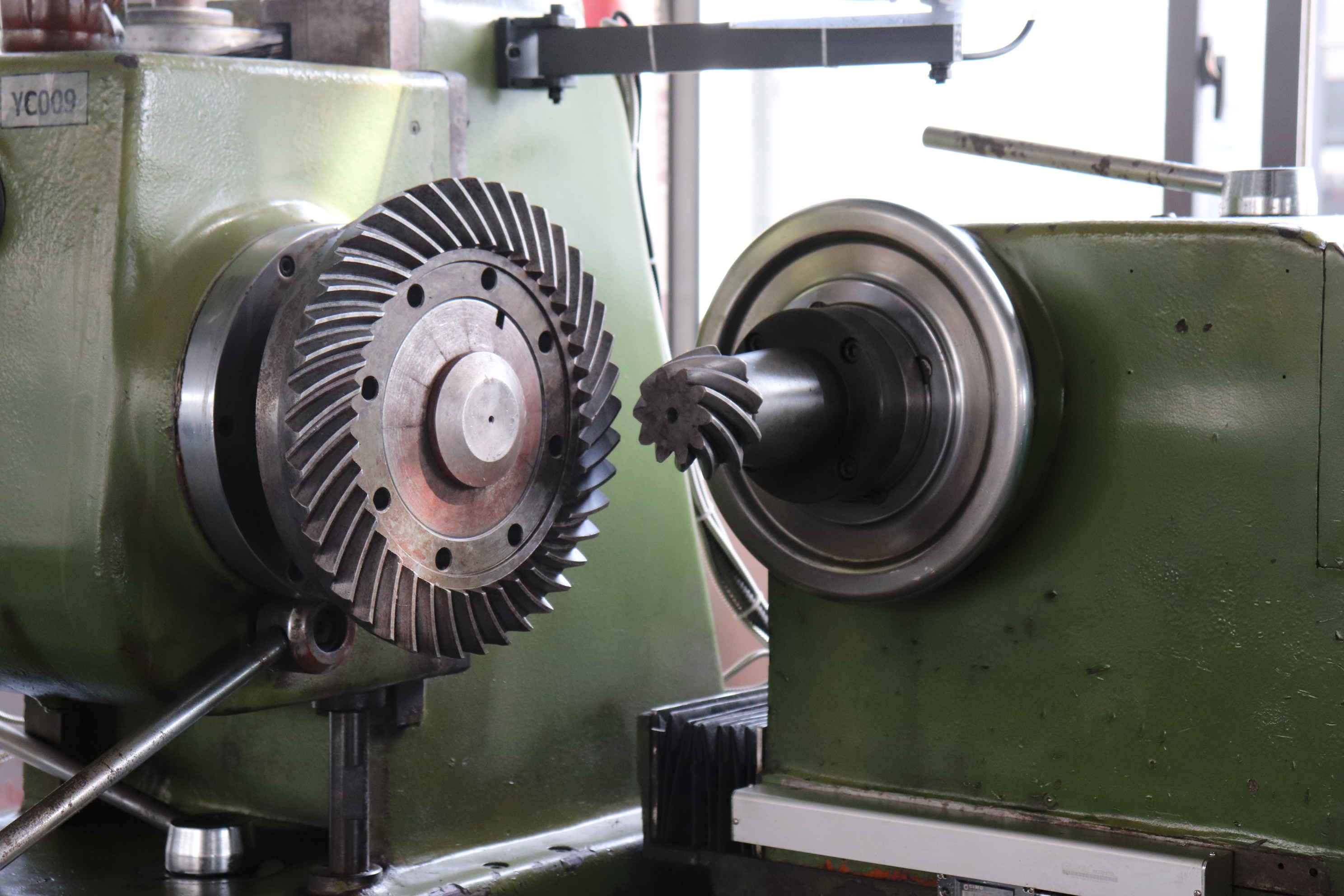

Engineered with a relentless pursuit of excellence, our bevel gear is the result of cutting-edge research, state-of-the-art manufacturing processes, and a passion for pushing the boundaries of what's possible. Every tooth of this gear has been carefully machined to exacting standards, ensuring a flawlessly smooth meshing with other transmission components. Say goodbye to power loss and inefficient energy transfer; this gear seamlessly optimizes power transfer from the engine to the wheels, amplifying your motorcycle's performance potential.

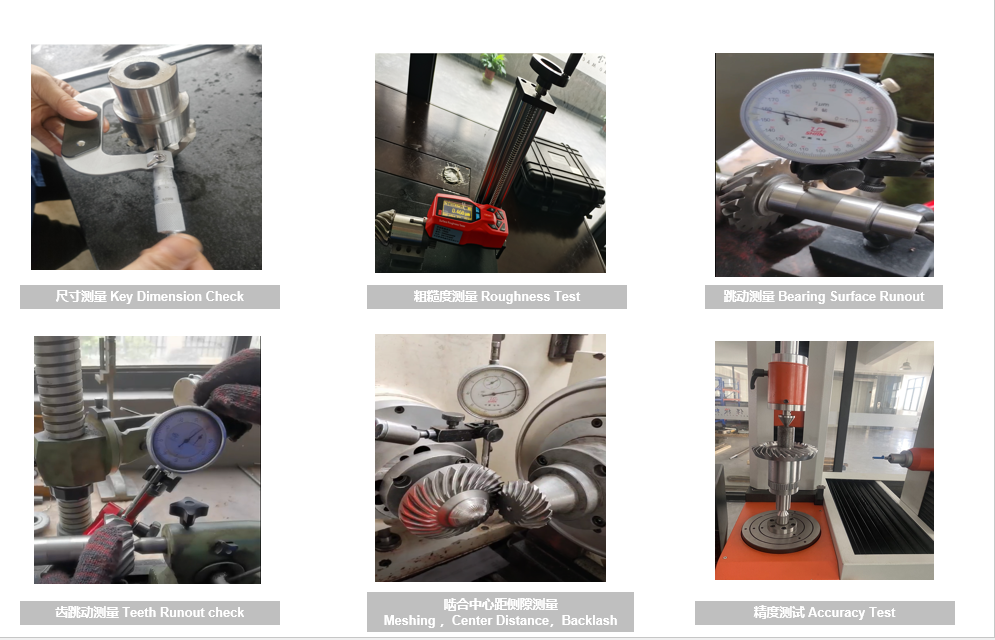

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

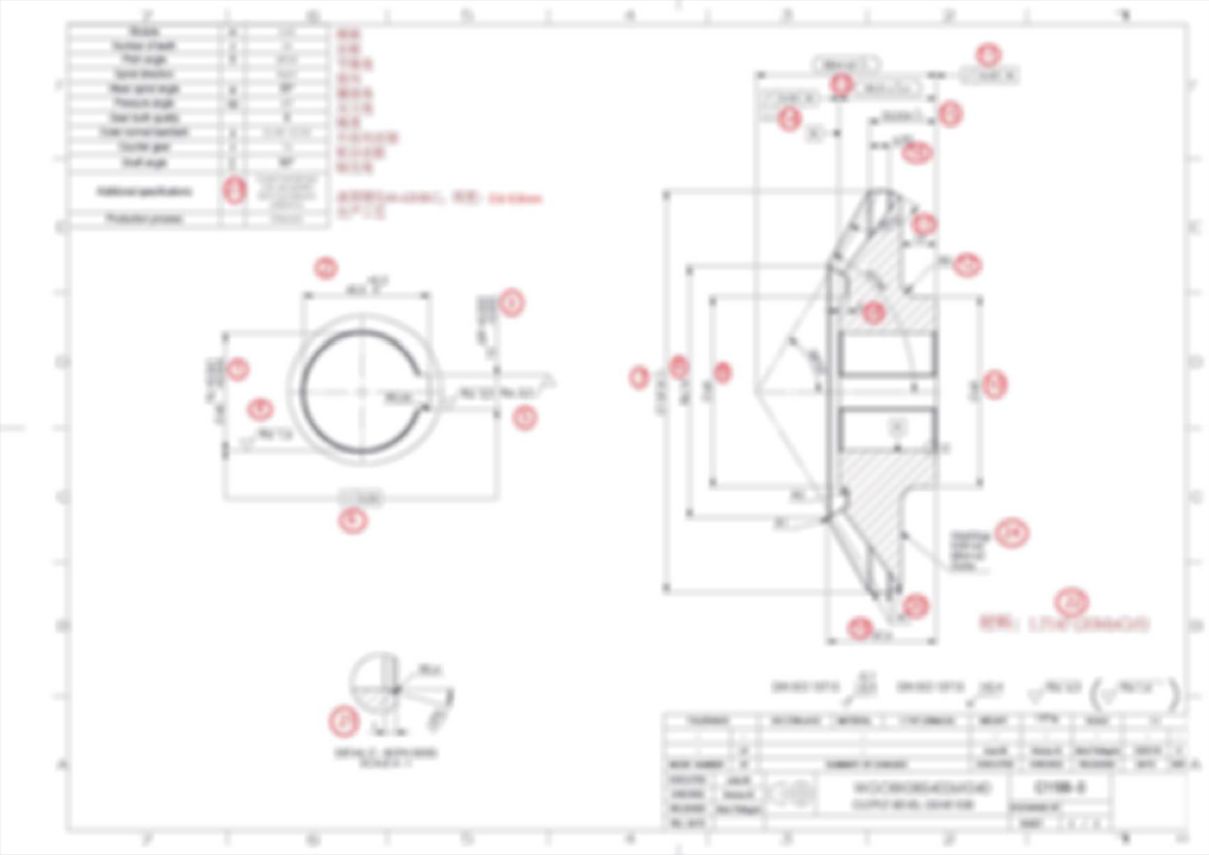

1.Bubble drawing

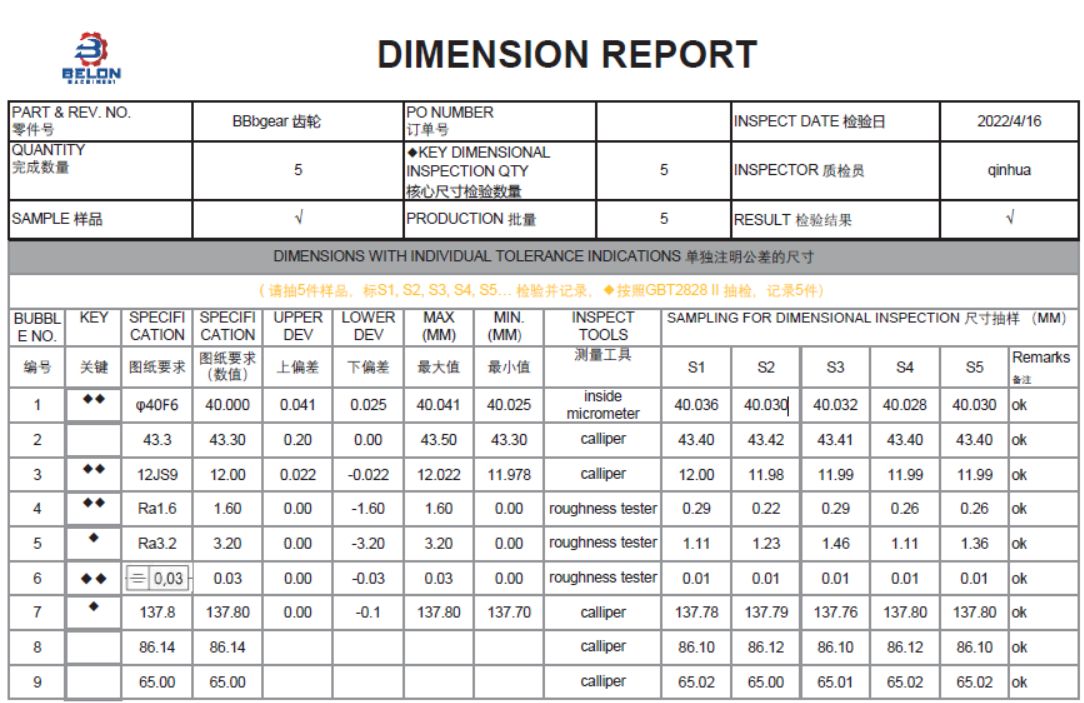

2.Dimension report

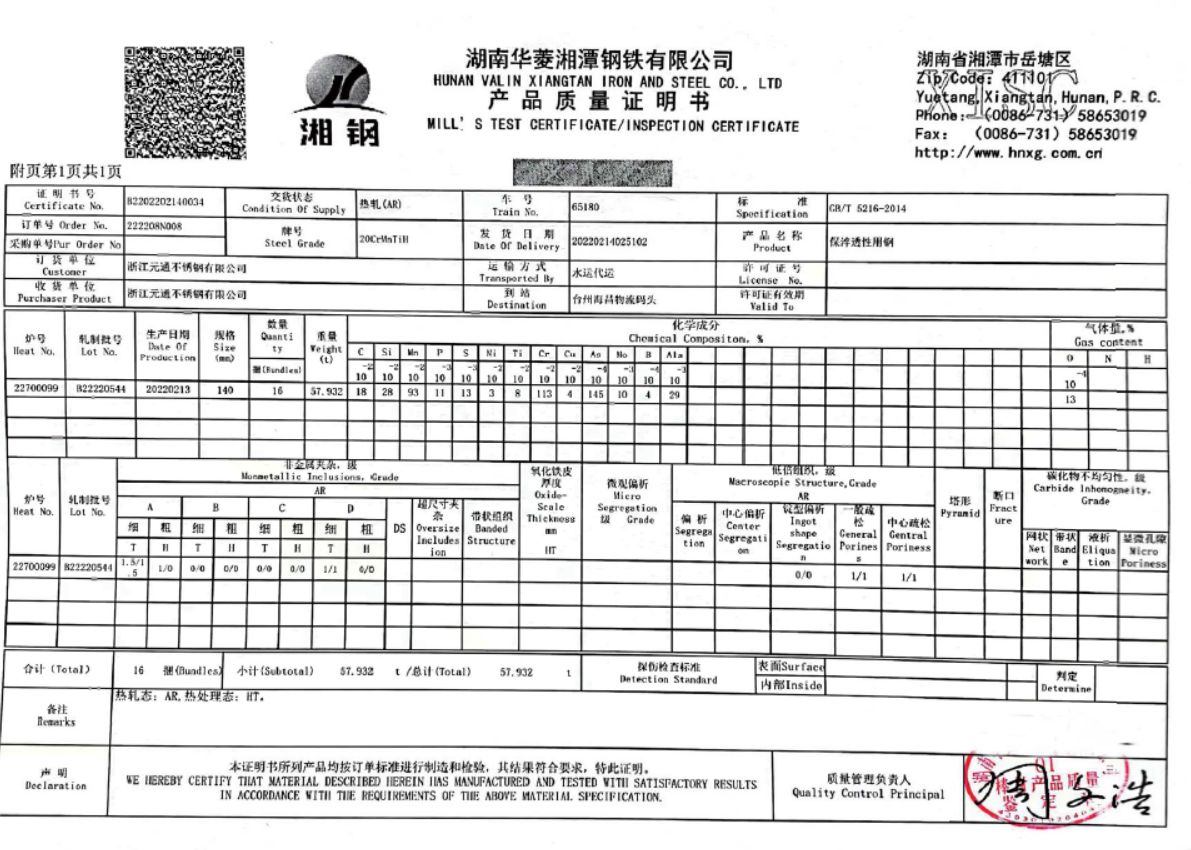

3.Material cert

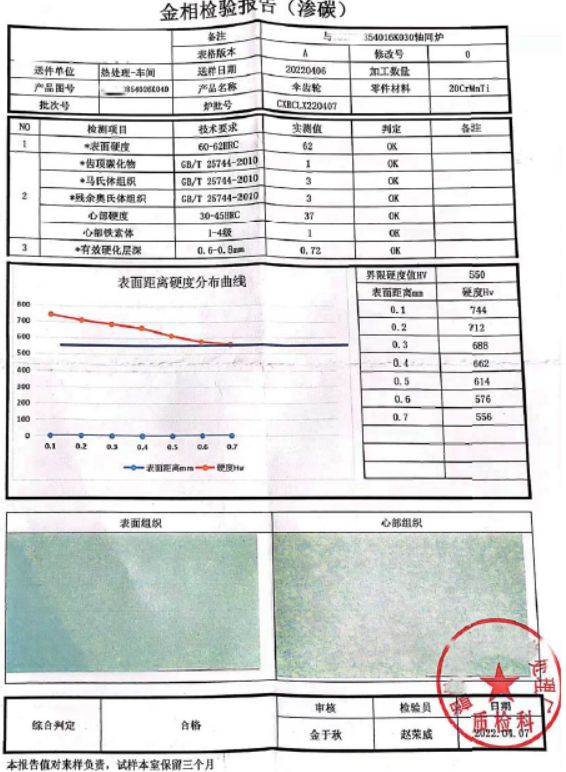

4.Heat treat report

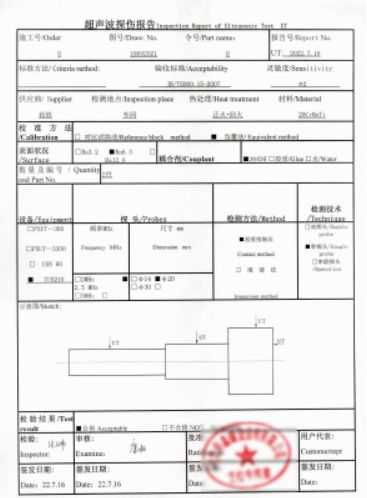

5.Ultrasonic Test report (UT)

6.Magnetic Particle Test report (MT)

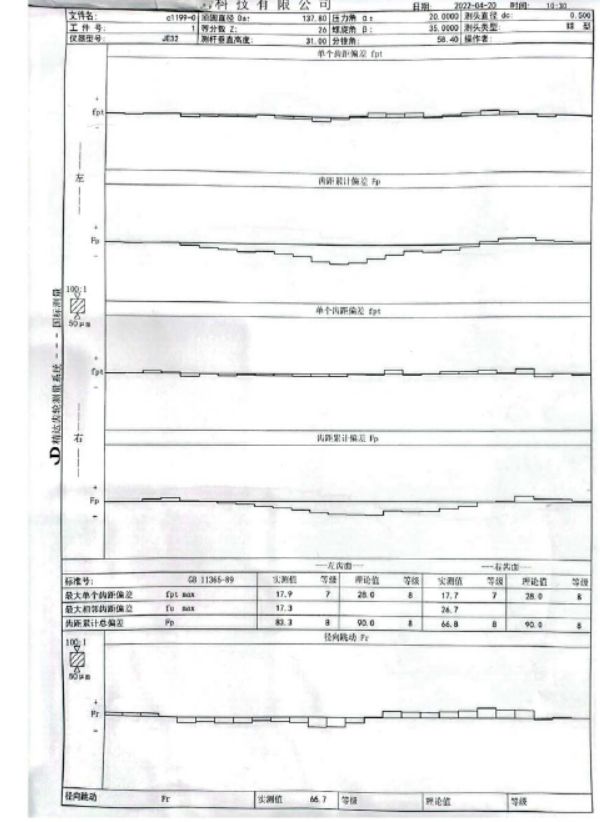

Meshing test report

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of GearsTeeth

→ Highest accuracy DIN5-6

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

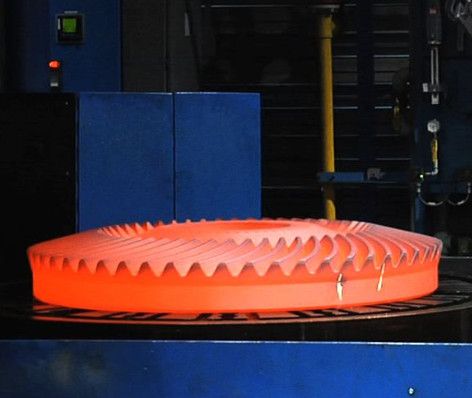

Forging

Lathe turning

Milling

Heat treat

OD/ID grinding

Lapping