High Performance Spline Gear Shaft for Industrial Applications

Our high performance spline gear shafts are designed to meet the demanding requirements of industrial applications, offering exceptional strength, precision, and durability. Manufactured from high-grade materials such as alloy steel or hardened stainless steel, these shafts ensure reliable performance under heavy loads and high torque conditions.

The spline design allows for smooth and efficient torque transfer while accommodating axial movement, making it ideal for use in gearboxes, pumps, conveyors, and other machinery. Precision machining ensures tight tolerances and superior alignment, reducing wear and extending the service life of your equipment.

Whether for custom or standard applications, our spline gear shafts are available in a variety of sizes, tooth profiles, and finishes, including tempered and polished surfaces, to suit your specific needs. Backed by rigorous quality control and compliance with industry standards such as ISO and AGMA, our spline gear shafts deliver unmatched performance for critical industrial operations.

Choose reliability and efficiency—choose our high-performance spline gear shafts for your industrial needs.

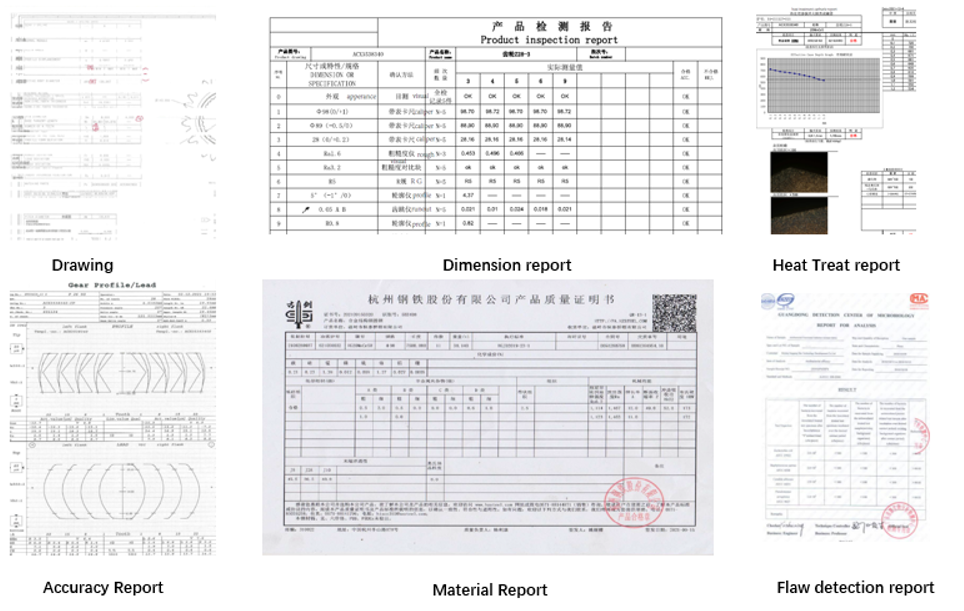

Inspection

Reports