High precision conical helical pinion gear used in gearmotor

The conical helical pinion gear is a type of bevel gear with helical teeth cut into a conical shape. Unlike straight bevel gears, which engage abruptly, conical helical pinion gears provide smoother and quieter operation due to their helical tooth design. This design allows for gradual, continuous contact between gears, reducing noise and vibration. They are used to transmit motion between shafts that are not parallel, making them ideal for automotive differentials and precision machinery. The helical angle of the teeth helps to distribute loads evenly, enhancing torque transmission and extending gear life. Conical helical pinion gears are valued for their efficiency, durability, and ability to handle high-torque applications.

We supplied different types of conical pinion gears from range from Module 0.5, Module 0.75,Module 1 ,Moule 1.25 mini gear shafts.

forging

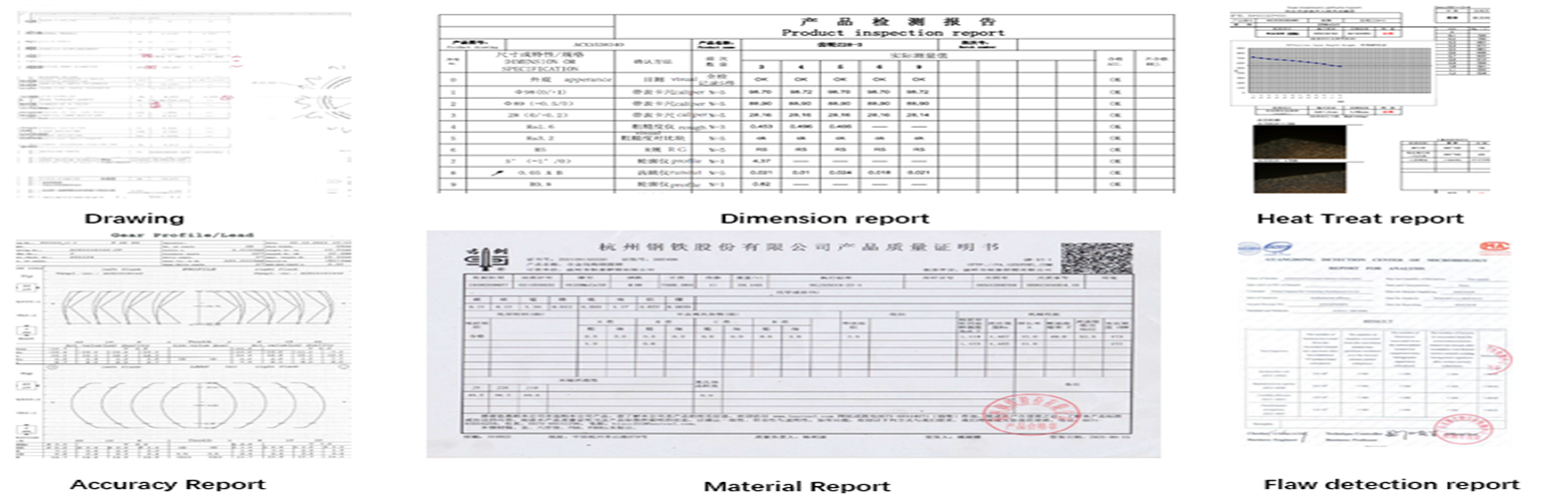

Inspection

Reports