Hot-selling Helical Gear Grinding - Internal Gear Used In Planetary Gearbox – Belon Detail:

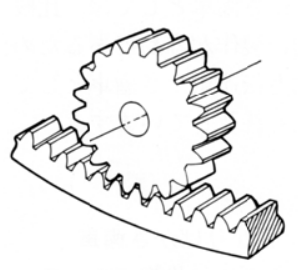

Internal gear Definition

An annular gear having teeth on the inner surface of its rim. The internal gear always meshes with an external gears like spur gears.

Manufacturing Plant

There are three automatic production lines for internal gears broaching, skiving.

Production Process

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

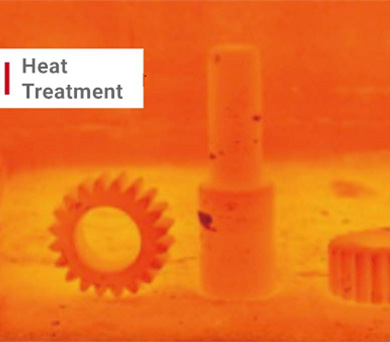

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

How To Test Internal Ring Gear And Make The Accurancy Report

How Internal Gears Produced To Speed Up Delivery

Internal Gear Grinding And Inspection

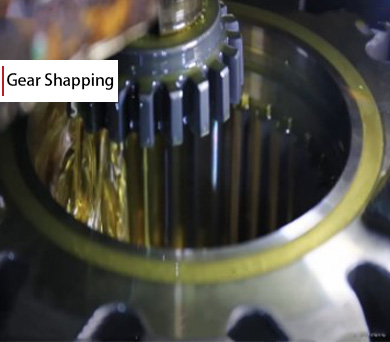

Internal Gear Shapping

Internal Gear Shapping

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Hot-selling Helical Gear Grinding - Internal Gear Used In Planetary Gearbox – Belon , The product will supply to all over the world, such as: Florence, Canada, Rwanda, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Write your message here and send it to us