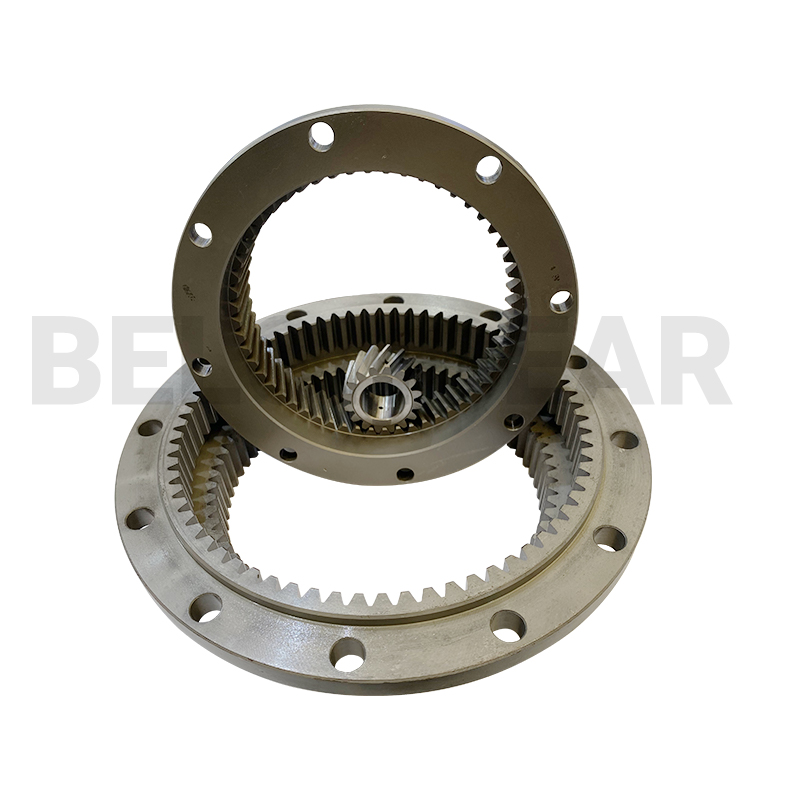

Internal spur gears for sale Detail:

Production Process

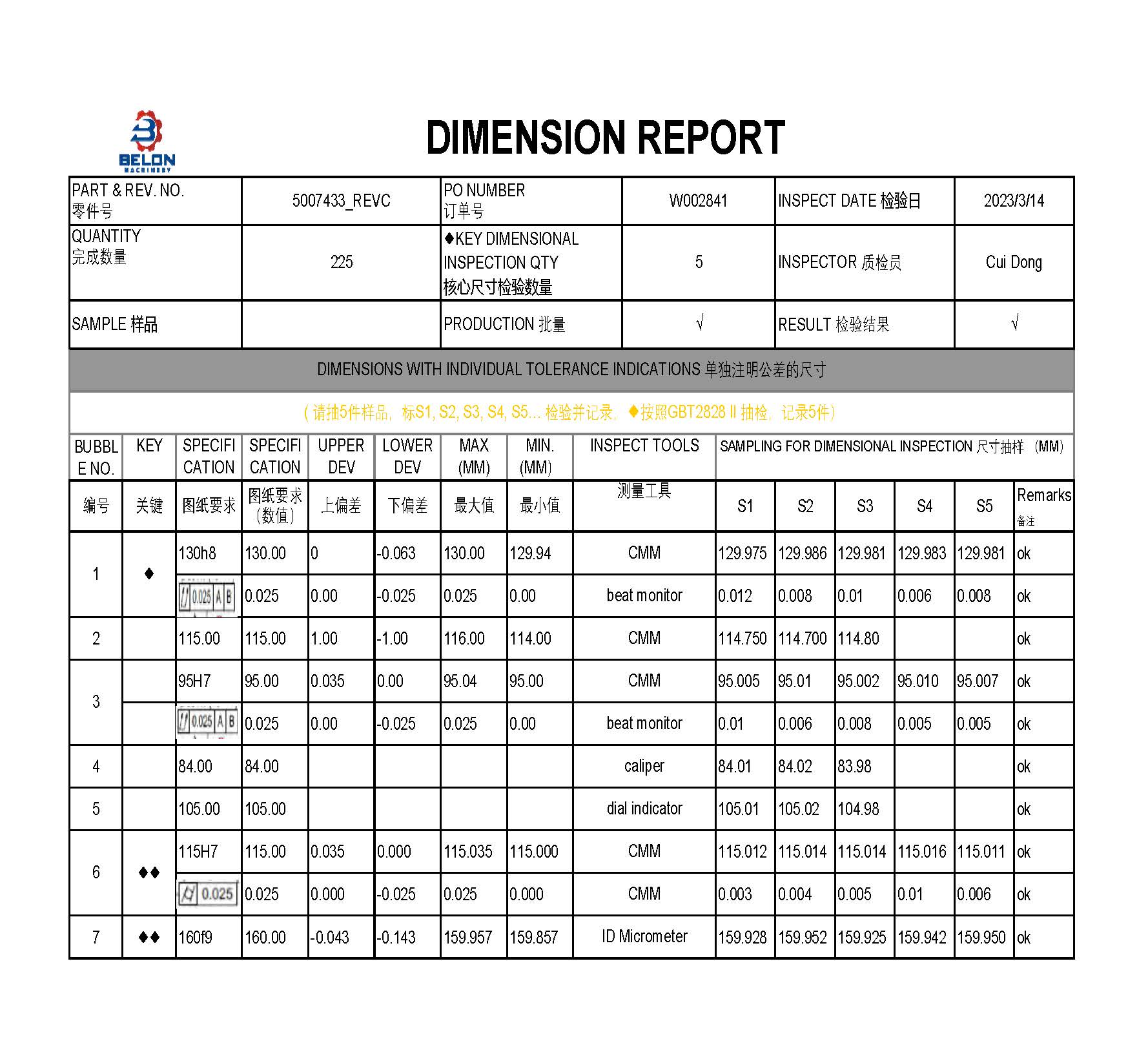

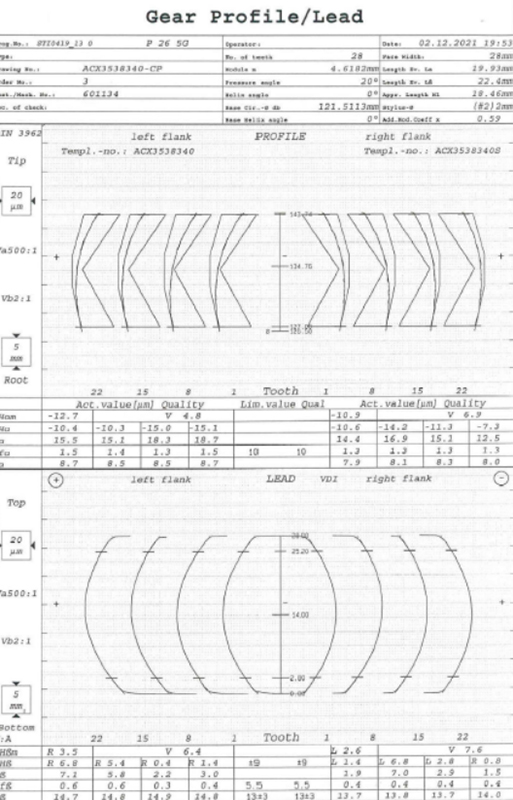

Inspection

Reports

Packages

Our video show

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Internal spur gears for sale , The product will supply to all over the world, such as: Croatia, Miami, United States, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

Write your message here and send it to us