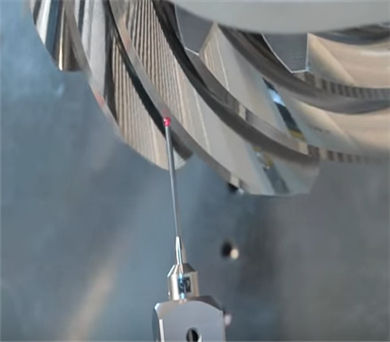

Lapping is one of the finishing processing methods of gears. The processing principle is to make the lapping gear and the lightly braked lapping wheel mesh freely with no gap, and add abrasive between the meshing tooth surfaces to make use of the relative sliding of the tooth surfaces. , to cut a very thin layer of metal from the tooth surface of the gear to be ground to achieve the purpose of reducing the surface roughness value and correcting the error of the gear part.

The precision of tooth lapping mainly depends on the precision of the gear before lapping and the precision of the lapping wheel, and lapping can only effectively improve the quality of the tooth surface and slightly correct the error of tooth shape and tooth orientation, but it has little improvement on other precisions.

Helical bevel gearboxes have a wide range of applications like

1) Metallurgy

2) Building materials

3) Mining

4) Petrochemical

5) Port lifting

6) Construction machinery

7) Rubber and plastic machinery

8) Sugar extraction

9) Electric power and other field

Raw Material

Rough Cutting

Gear Turning

Quenching & Tempering

Gear Milling

Heat Treat

Gear Lapping

Testing

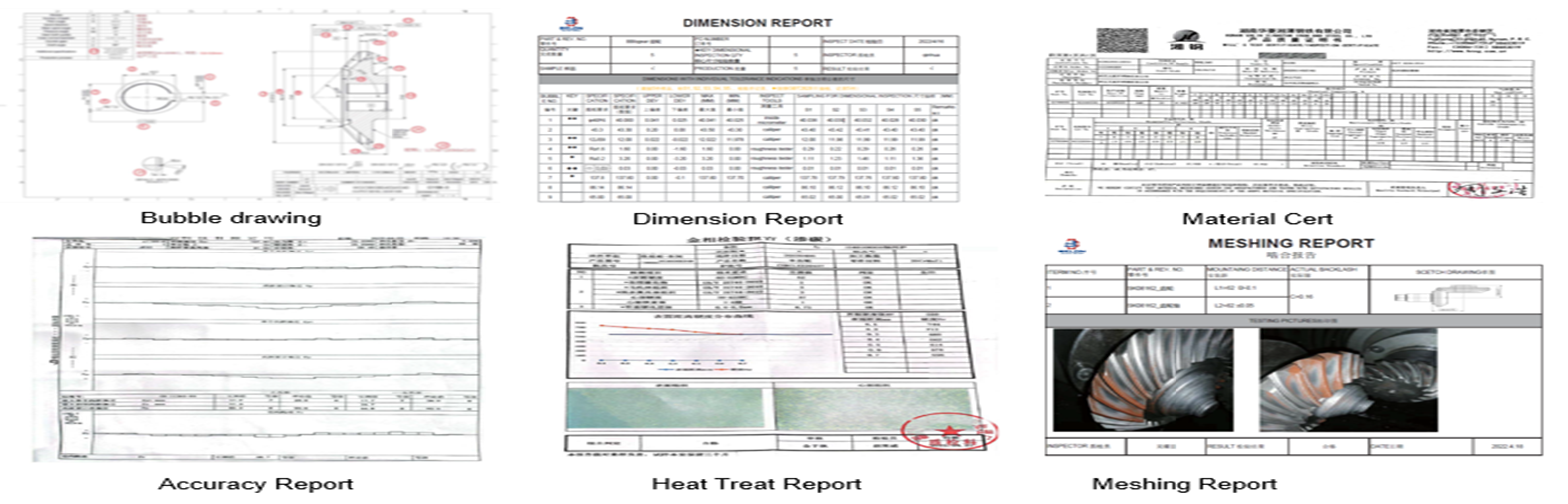

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Inner package

Inner package

Carton

wooden package