Leading Manufacturer for Bevel Pinion Shaft - Alloy steel Lapped bevel gear sets in gearmotor – Belon Detail:

Product details

These kinds of bevel gear set are used at types of gearmotors and some of them are common types .,with low noise and high wear-resistant .

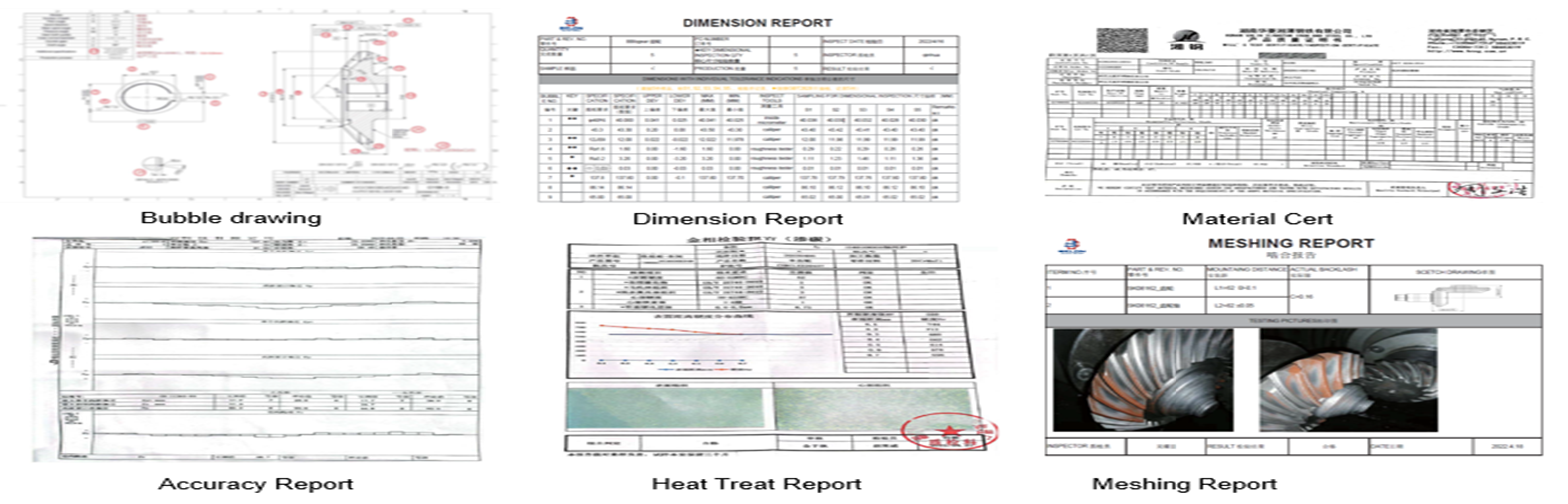

The important reports for such kinds of bevel gears are :

1) Dimension report (plus bearing surface runout testing video)

2) Material report before heat treat

3) Heat Treat report plus hardness and Metallographic

4) Accuracy test report

5) Meshing Test report (plus center distance ,backlash testing videos)

The production process for such kinds of bevel gears set is as following :

1) Forging

2) Rough cutting

3) Gear turning

4) Quenching and tempering heat treat

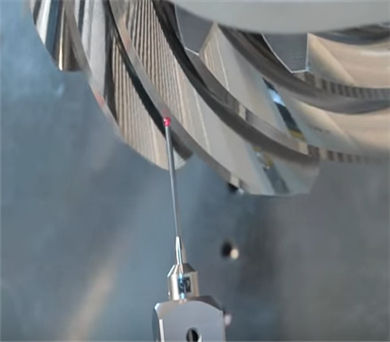

5) Gear milling for teeh

6) Heat Treat like carburizing

7) Gear Lapping in order to improve the gear surface quality

8) Complete inspection

Manufacturing Plant :

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

Production Process:

Raw Material

Rough Cutting

Gear Turning

Quenching & Tempering

Gear Milling

Heat Treat

Gear Lapping

Testing

Inspection :

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Packages :

Inner package

Inner package

Carton

wooden package

Our video show

Industrial gearbox spiral bevel gear milling

Meshing test for lapping bevel gear

Surface runout testing for bevel gears

Lapping bevel gear or grinding bevel gears

Spiral bevel gears

Bevel gear broaching

Bevel gear lapping VS bevel gear grinding

Spiral bevel gear milling

Industrial robot spiral bevel gear milling method

Product detail pictures:

Related Product Guide:

All we do is always associated with our tenet " Customer first, Trust first, devoting on the food packaging and environmental protection for Leading Manufacturer for Bevel Pinion Shaft - Alloy steel Lapped bevel gear sets in gearmotor – Belon , The product will supply to all over the world, such as: Suriname, San Diego, Holland, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!