Leading Manufacturer for Bevel Pinion Shaft - Gleason bevel gear for tractors – Belon Detail:

Product details

This bevel gear set was used in tractor . In the tractor , it is located in front of the driving wheel and behind the gearbox . All the transmission mechanisms and shells are called the rear axle, and its main function is to step up, increase, decelerate and change the torque .In addition to tractors with transverse engines that use cylindrical gear pairs as central transmission, most of them use bevel gear pairs, which not only increase torque and reduce speed, but also change torque transmission.

Manufacturing Plant :

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

Production Process:

Raw Material

Rough Cutting

Gear Turning

Quenching & Tempering

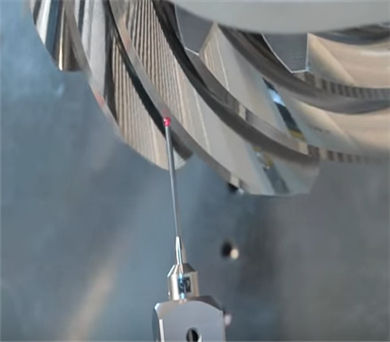

Gear Milling

Heat Treat

Gear Lapping

Testing

Inspection :

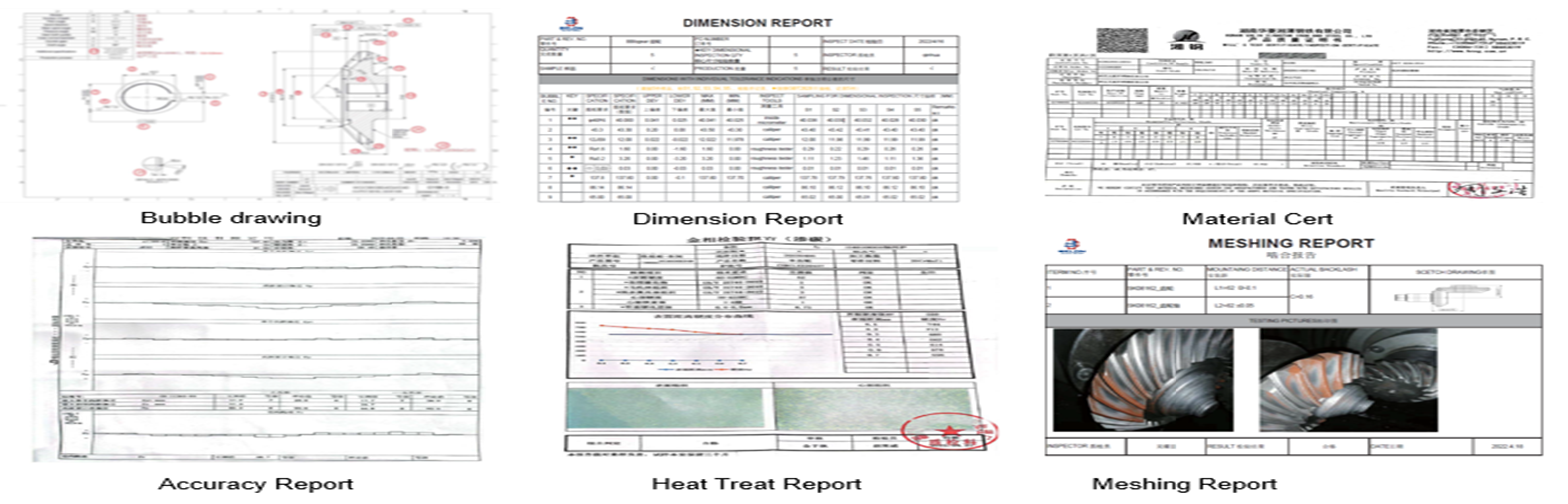

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Packages :

Inner package

Inner package

Carton

wooden package

Our video show

Industrial gearbox spiral bevel gear milling

Meshing test for lapping bevel gear

Surface runout testing for bevel gears

Lapping bevel gear or grinding bevel gears

Spiral bevel gears

Bevel gear broaching

Bevel gear lapping VS bevel gear grinding

Spiral bevel gear milling

Industrial robot spiral bevel gear milling method

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Leading Manufacturer for Bevel Pinion Shaft - Gleason bevel gear for tractors – Belon , The product will supply to all over the world, such as: European, Bahrain, Mongolia, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.