Low MOQ for Bevel Gear Pair - DIN8 bevel gear and pinion in bevel helical gearmotors – Belon Detail:

Product details

These kinds of bevel gear and pinion are used at bevel helical gearmotor which are particularly suitable for conveyor applications. They offer great flexibility thanks to their solid and hollow output shaft options.

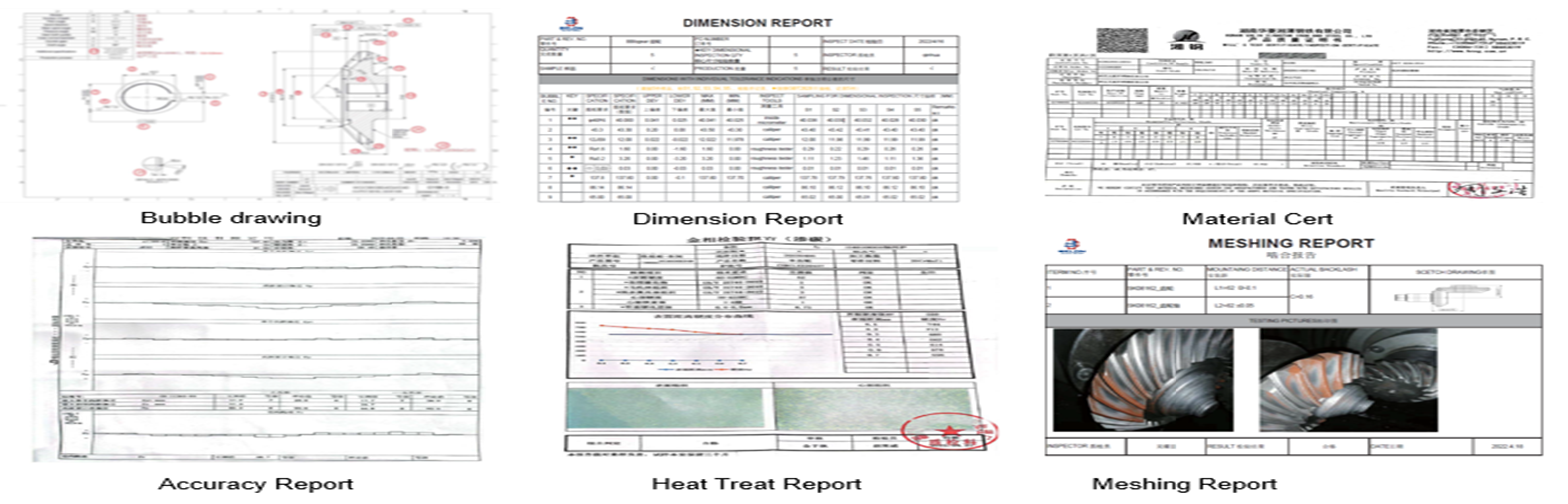

The important reports for such kinds of bevel gears are :

1) Dimension report (plus bearing surface runout testing video)

2) Material report before heat treat

3) Heat Treat report plus hardness and Metallographic

4) Accuracy test report

5) Meshing Test report (plus center distance ,backlash testing videos)

Manufacturing Plant :

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

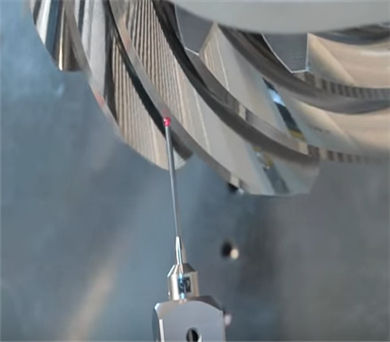

Production Process:

Raw Material

Rough Cutting

Gear Turning

Quenching & Tempering

Gear Milling

Heat Treat

Gear Lapping

Testing

Inspection :

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Packages :

Inner package

Inner package

Carton

wooden package

Our video show

Industrial gearbox spiral bevel gear milling

Meshing test for lapping bevel gear

Surface runout testing for bevel gears

Lapping bevel gear or grinding bevel gears

Spiral bevel gears

Bevel gear broaching

Bevel gear lapping VS bevel gear grinding

Spiral bevel gear milling

Industrial robot spiral bevel gear milling method

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for Low MOQ for Bevel Gear Pair - DIN8 bevel gear and pinion in bevel helical gearmotors – Belon , The product will supply to all over the world, such as: Guinea, Indonesia, Oman, We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.