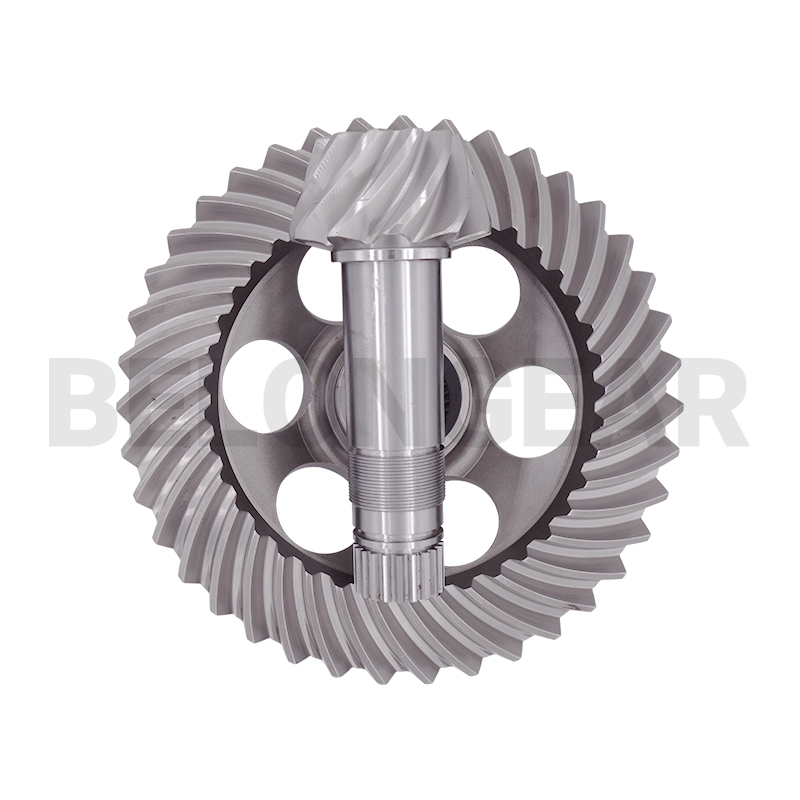

Low MOQ for Bevel Gear Pair - Straight Bevel Gear Used In Differential Gear Unit – Belon Detail:

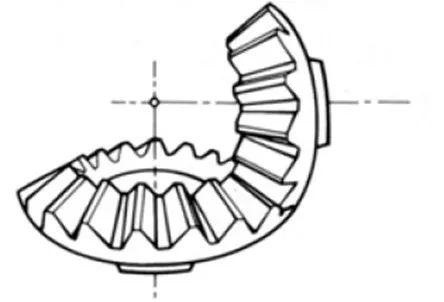

Straight Bevel Gear Definition

A simple form of bevel gear having straight teeth which ,if extended inward ,would come together at the intersection of the shaft axles .

Straight Bevel Gear Features:

1) Relatively easy to manufacture

2) Provides reduction ratios up to approx..1:5

Straight Bevel Gear Application:

Straight bevel gears are usually used in machine tools ,printing processes , harvester especially suitable for use as a differential gear unit

Manufacturing Plant

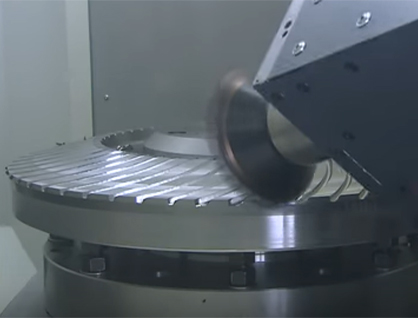

Production Process

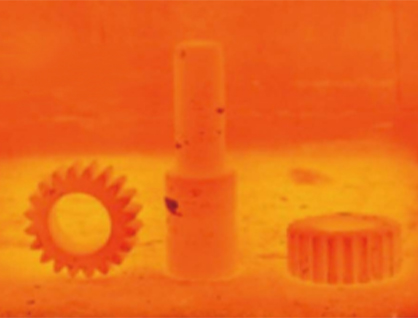

Raw Material

Rough Cutting

Turning

Quenching And Tempering

Gear Milling

Heat Treat

Gear Planning

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

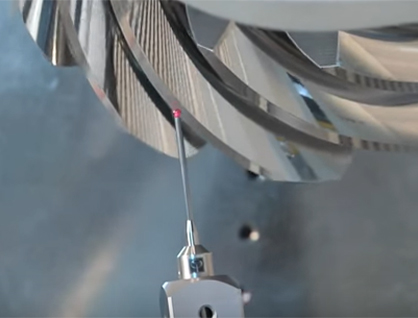

Straight Bevel Gear Machining Way

How To Machine Straight Bevel Gear

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Low MOQ for Bevel Gear Pair - Straight Bevel Gear Used In Differential Gear Unit – Belon , The product will supply to all over the world, such as: Slovenia, Boston, Marseille, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Write your message here and send it to us