Low price for Worm Gear And Worm Wheel - Worm Gear Used In Worm Gearboxes – Belon Detail:

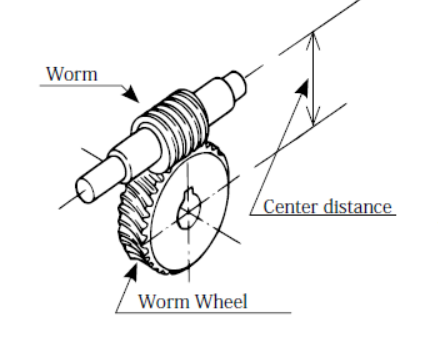

Worm Gears Definition

Worm is a shank having at least one complete tooth(thread) around the pitch surface and is the driver of a worm wheel.Worm wheel is a gear with teeth cut on an angle to be driven by a worm.The worm gear pair is used to transmit motion between two shafts which are at 90°to each other and lie on a plane.

Worm gears Applications:

Speed reducers, antireversing gear devices making the most of its self-locking features, machine tools, indexing devices, chain blocks, portable generators etc

Worm gears features:

1. Provides large reduction raios for a given center distance

2. Quite and smooth meshing action

3. It is not possible for a worm wheel to drive a wor unless certain conditions are met

Worm gear working principle:

The two shafts of the worm gear and worm drive are perpendicular to each other; the worm can be regarded as a helix with one tooth (single head) or several teeth (multiple heads) wound along the helix on the cylinder, and the worm gear is like an oblique gear, but its teeth enclose the worm. During meshing, one rotation of the worm will drive the worm wheel to rotate through one tooth (single-end worm) or several teeth (multi-end worm).rod), so the speed ratio i of the worm gear transmission = the number of heads of the worm Z1/the number of teeth of the worm wheel Z2.

Manufacturing Plant

Top ten enterprises in china, equipped with 1200 staff, obtained total 31 inventions and 9 patents .Advanced manufacturing equipment, heat treat equipment, inspection equipment.

Production Process

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

Worm Gear Center Of Distance And Mating Inspection

Gears # Shafts # Worms Display

Worm Wheel And Helical Gear Hobbing

Automatic Inspection Line For Worm Wheel

Worm Shaft Accuracy Test Iso 5 Grade # Alloy Steel

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for Low price for Worm Gear And Worm Wheel - Worm Gear Used In Worm Gearboxes – Belon , The product will supply to all over the world, such as: Ecuador, California, Netherlands, Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.Thanks.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!