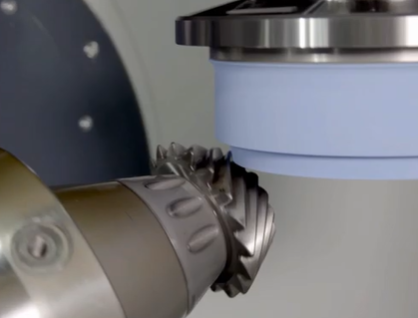

Manufacturer suppliers Spiral Bevel Gear Set Detail:

Our spiral bevel gear units are available in a range of sizes and configurations to suit different heavy equipment applications. Whether you need a compact gear unit for a skid steer loader or a high-torque unit for a dump truck, we have the right solution for your needs. We also offer custom bevel gear design and engineering services for unique or specialized applications, ensuring that you get the perfect gear unit for your heavy equipment.

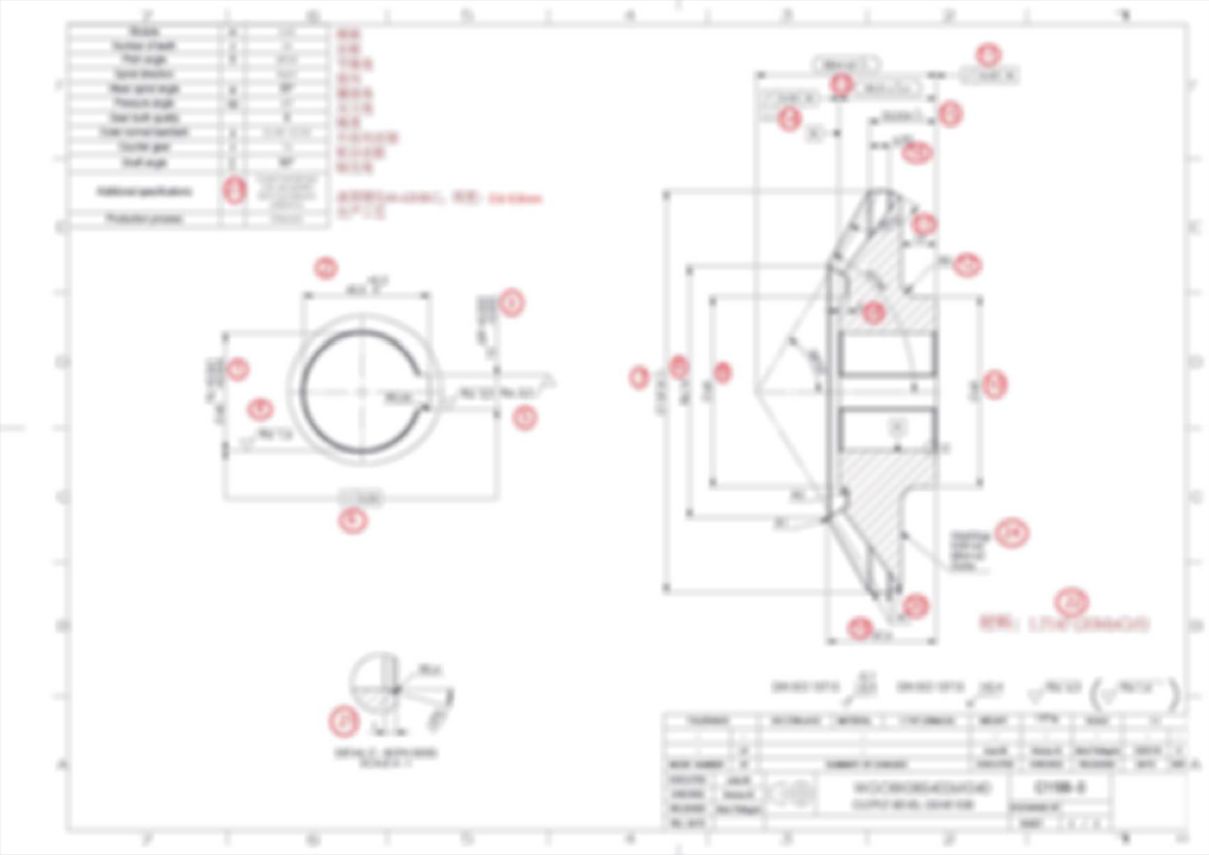

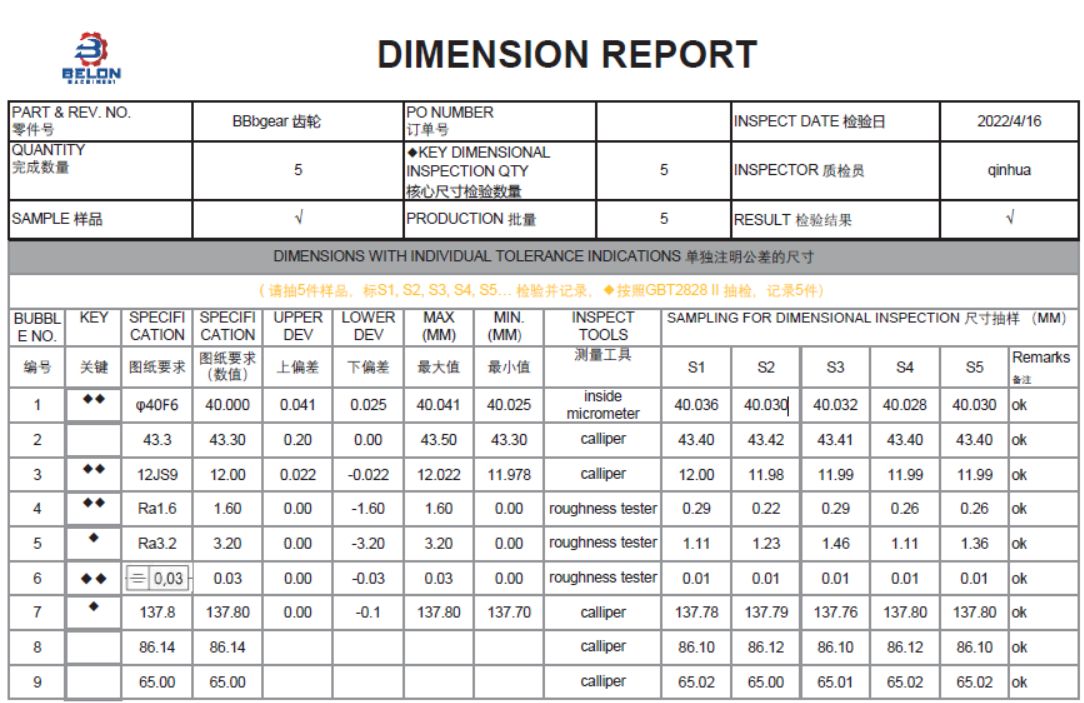

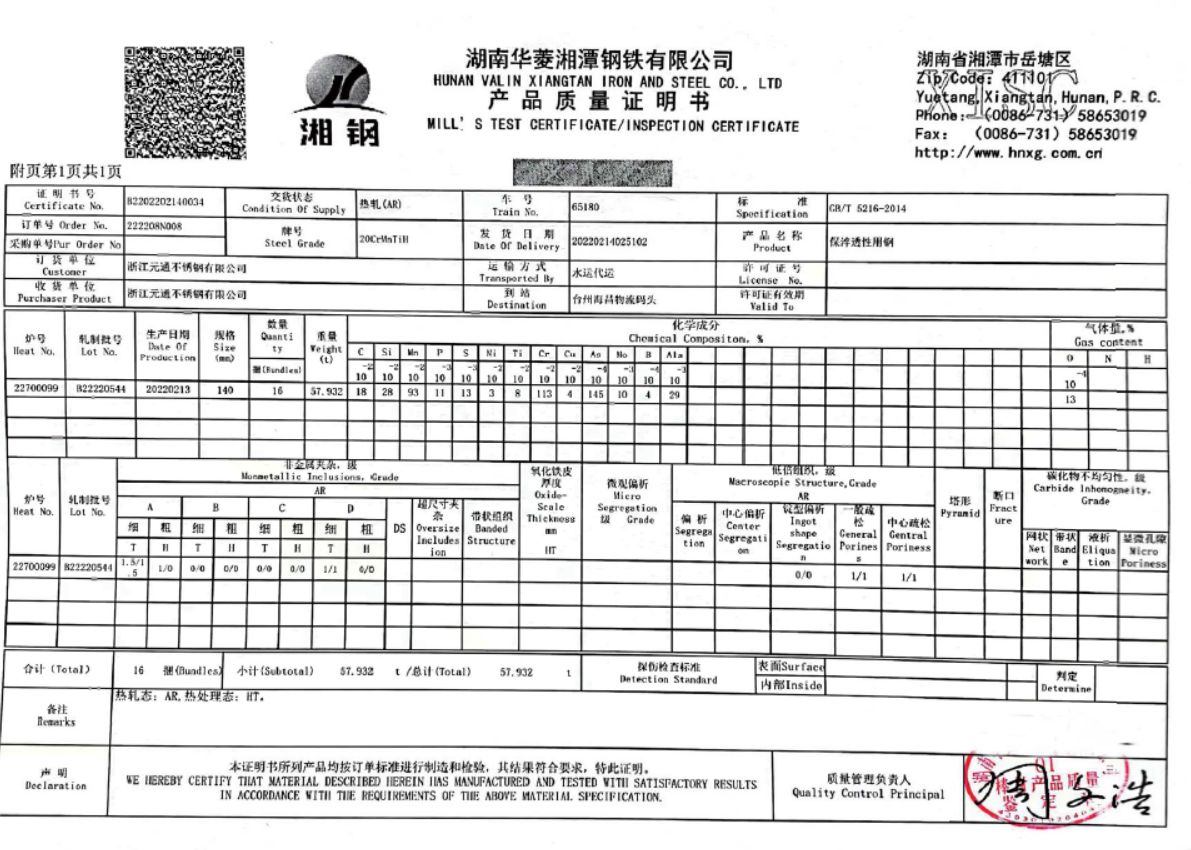

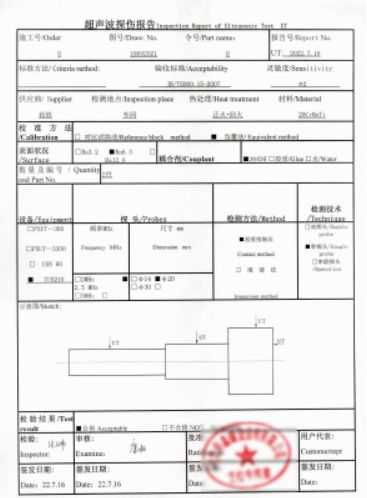

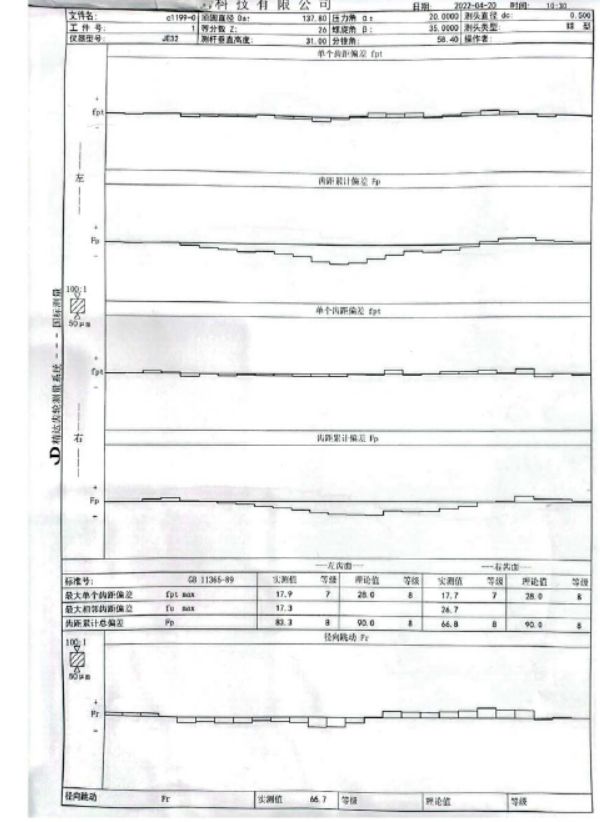

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears?

1) Bubble drawing

2) Dimension report

3) Material cert

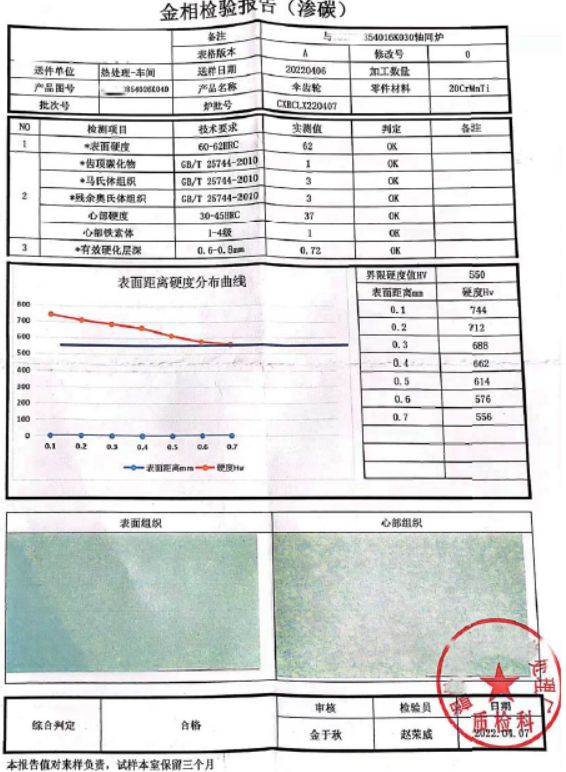

4) Heat treatment report

5) Ultrasonic Test report (UT)

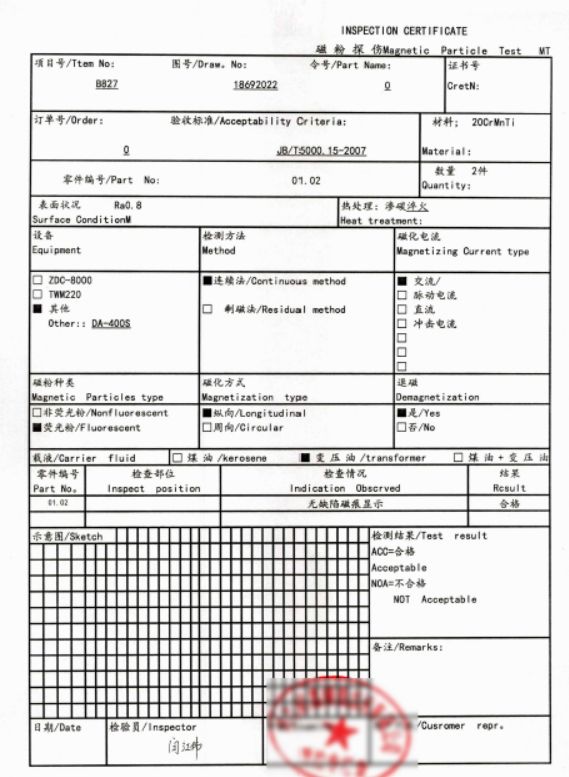

6) Magnetic Particle Test report (MT)

Meshing test report

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

raw material

rough cutting

turning

quenching and tempering

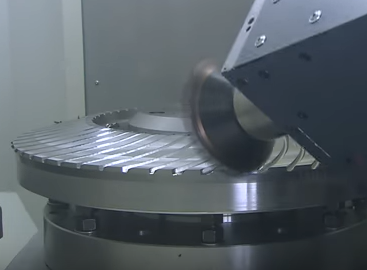

gear milling

Heat treat

gear grinding

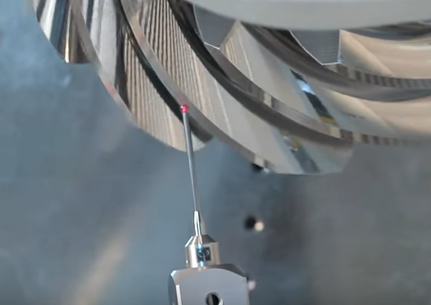

testing

Inspection

Packages

Our video show

Product detail pictures:

Related Product Guide:

Our pursuit and corporation aim should be to "Always satisfy our consumer requirements". We carry on to build and style and design remarkable quality items for both our outdated and new clients and reach a win-win prospect for our clients at the same time as us for Manufacturer suppliers Spiral Bevel Gear Set , The product will supply to all over the world, such as: kazakhstan, Nigeria, Boston, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.