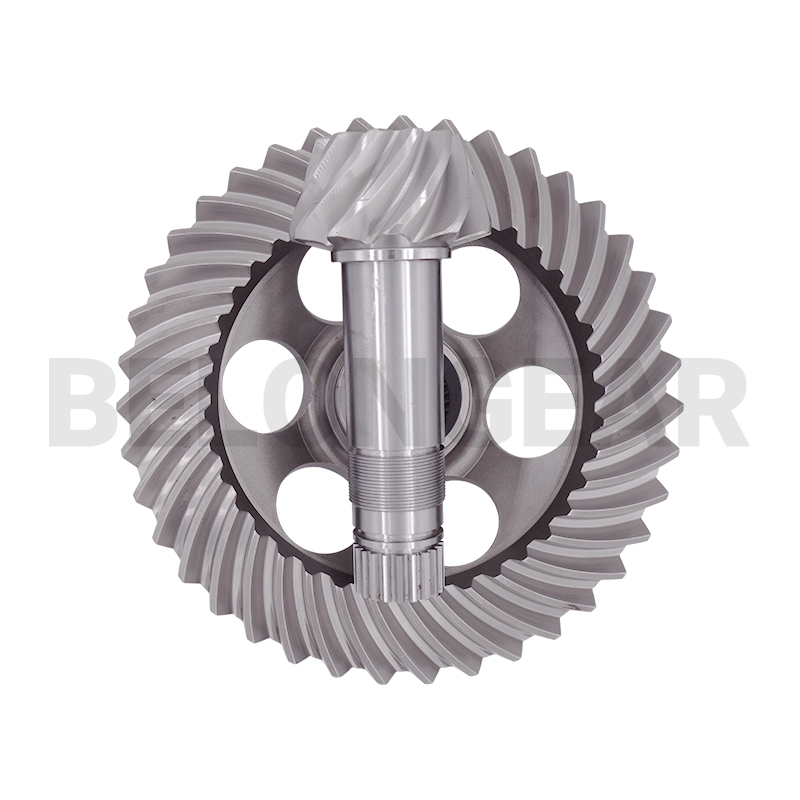

Newly Arrival High Precision Bevel Gears - Spiral Bevel Gear Set In Automotive Gearboxes – Belon Detail:

Features

This type of spiral bevel gear set is commonly used in axle products, mostly in rear-wheel-drive passenger cars, SUVs and commercial vehicles. Some electric buses will also be used. The design and processing of this kind of gear are more complicated. At present, it is mainly made by Gleason and Oerlikon. This kind of gear is divided into two types: equal-height teeth and tapered teeth. It has many advantages such as high torque transmission, smooth transmission, and good NVH performance. Because it has the characteristics of offset distance, it can be considered on the ground clearance of the vehicle to improve the pass ability of the vehicle.

Processing Types

There are two types: face milling type and face hobbing type. The face hobbing type is the generating processing method, which is suitable for the design of equal-height teeth. This kind of gear needs to be paired and ground after processing, marked well, and needs to be assembled one by one. correspond. The face milling type is similar to the forming method, and it is suitable for the reduction teeth. After processing, it can be combined with the grinding process. In theory, there is no need for one-to-one correspondence during assembly.

Manufacturing Plant

Production Process

Raw Material

Rough Cutting

Turning

Quenching And Tempering

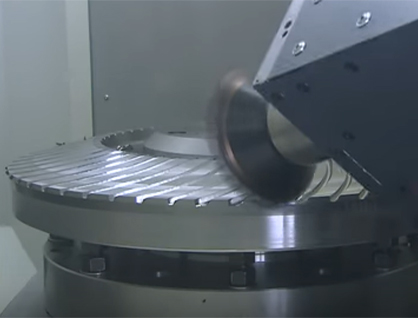

Gear Milling

Heat Treat

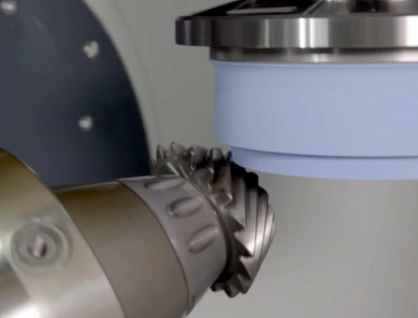

Gear Grinding

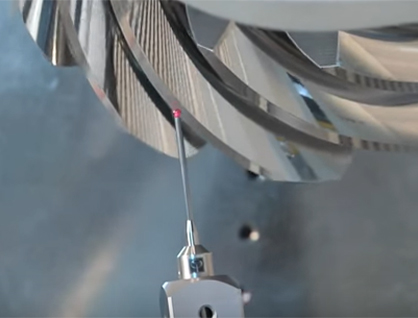

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

Lapping Bevel Gear Or Grinding Bevel Gears

Bevel Gear Lapping Vs Bevel Gear Grinding

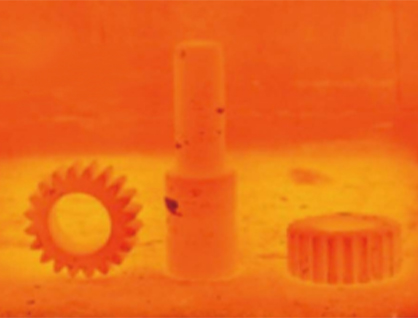

Spiral Bevel Gears

Bevel Gear Broaching

Spiral Bevel Gear Milling

Industrial Robot Spiral Bevel Gear Milling Method

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Newly Arrival High Precision Bevel Gears - Spiral Bevel Gear Set In Automotive Gearboxes – Belon , The product will supply to all over the world, such as: Oman, Montreal, India, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!