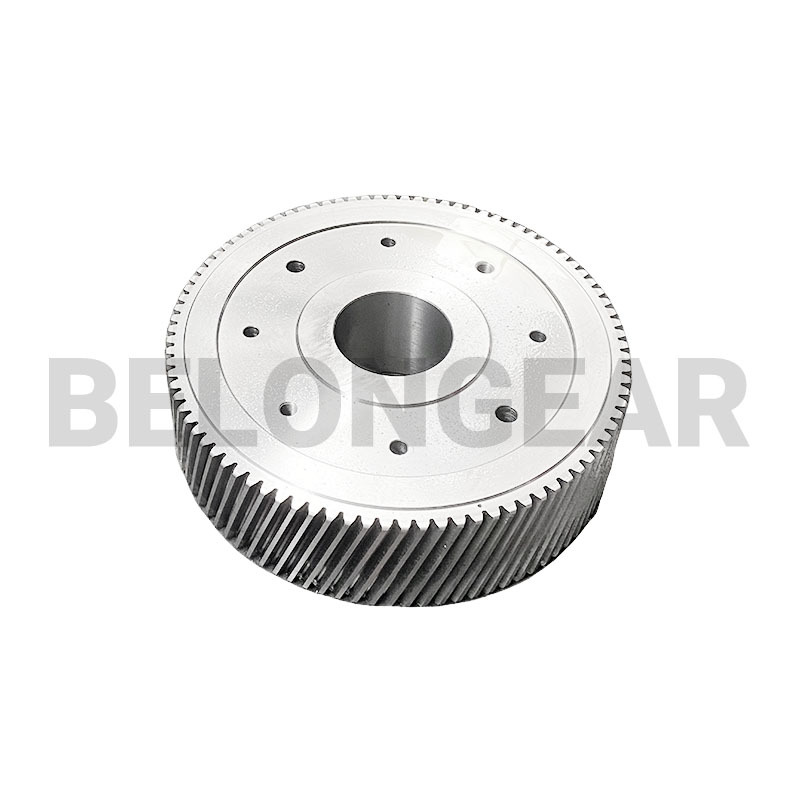

The application of helical gears in mining conveyors is multifaceted. Their main feature is that the tooth profile is a helix, which allows for smooth operation and reduced noise during meshing. Here are some applications of helical gears in mining conveyors:

Smooth Power Transmission: Helical gears can provide smooth power transmission, which is very important for mining conveyors as they need to operate stably under various loads. The helical shape of the gears helps to distribute the load, reducing the pressure between the gears and thus extending their service life.

Noise and Vibration Reduction: Due to the more gradual engagement of helical gears, they generate less noise and vibration during operation compared to straight gears. This is crucial for improving the comfort and safety of the mining work environment.

Efficiency Improvement: The design of helical gears can increase the efficiency of gearboxes because they can transmit power more effectively. This is a significant advantage for mining conveyors, which often need to operate under high loads.

Suitable for High-Load Applications: Mining conveyors often need to work under high-load conditions. Helical gears, due to their unique design, can withstand large axial and radial loads.

View more products Helical gears

Hypoid gear manufacturer Belon gears

Maintenance and upkeep: Maintenance of mining conveyors is crucial to ensure continuous operation and safety. The design of helical gears can simplify the maintenance process because their smoother operation reduces the risk of wear and failure.

Safety Enhancement: Mining is a high-risk industry, so the safety of conveyors is very important. Helical gears can reduce the risk of belt slippage and deviation from the track, thereby increasing the safety of the entire conveyor system.

Adaptability: Helical gears can be designed in different sizes and tooth numbers to meet the needs of different mining conveyors. This flexibility allows helical gears to be used in a variety of mining applications, from small conveyors to large, high capacity conveying systems.

High Durability: Mining environments are often very harsh, including dusty, humid, and corrosive conditions. The design and material selection of helical gears can ensure their durability and reliability under these conditions.

Overall, the application of helical gears in mining conveyors provides efficient, reliable, and safe power transmission, which helps to increase production efficiency and reduce maintenance costs.

Spiral Gear vs Helical Gear A Comparative Analysis

Post time: Oct-21-2024