Application of Large Size Bevel Gears in Crusher

Large bevel gears are used to drive crushers for processing ore and minerals in the hard rock mining and mining industries. The most common of these machines are rotary crushers and cone crushers. Rotary crushers are often the first step after initial blasting in a mine or quarry, and the largest machines are capable of processing 72-inch and red rocks for fist sized products. Cone crushers typically serve in secondary and tertiary crushing applications where further size reduction is required. In this case, the gears of large machines are now approaching 100 inches in diameter.

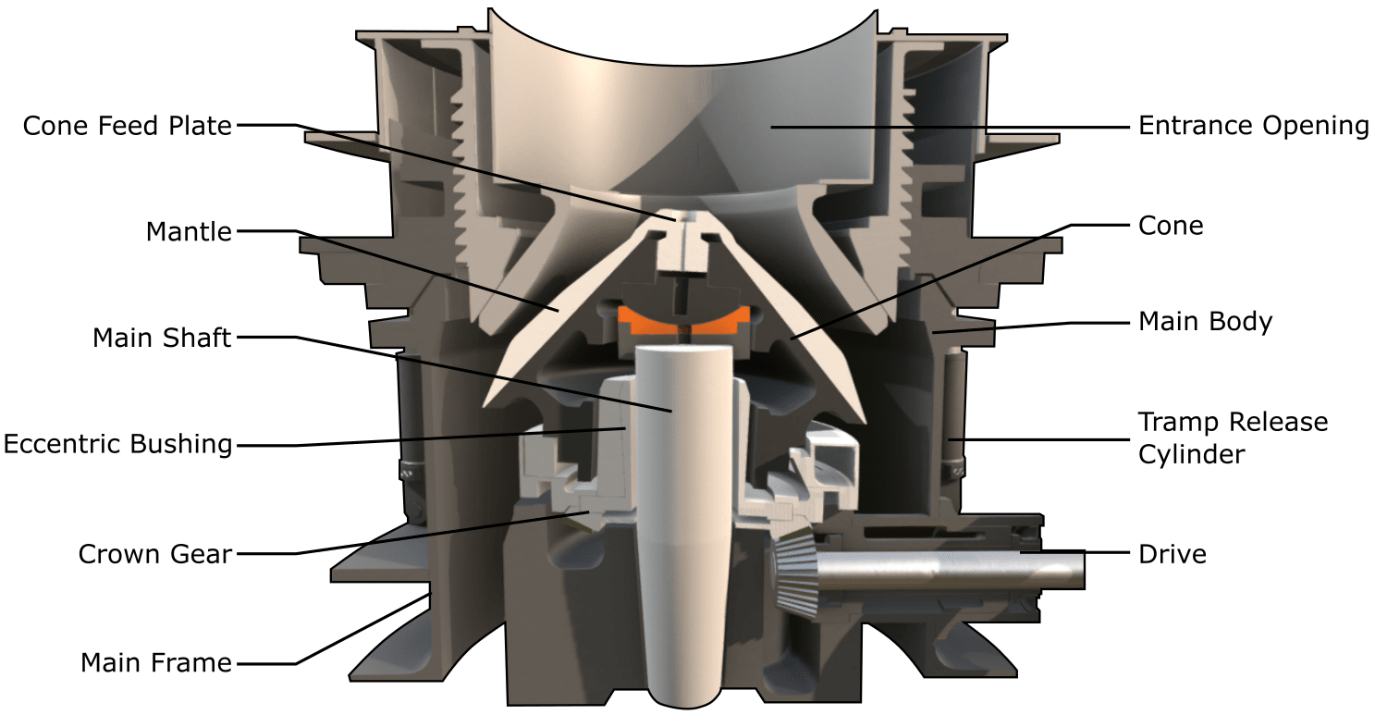

Both types of crushers consist of a conical cone crushing chamber with a fixed conical casing surrounding a rotating conical cover plate. These two main parts form a conical crushing chamber with the largest opening at the top, into which the raw material is crushed and reduced in size. The crushed material goes down by gravity, and after reaching the desired size, it is finally discharged from the bottom.

Over time, the oldest crusher tooth profiles still use straight bevel gears, and quite a few of these machines are still in operation today. As throughput and power ratings increased, and hardness increased, the industry responded further with spiral bevel gear designs. However, because the processing, measurement and installation of straight bevel gears are relatively simple and the production cost is low, they are still the most widely used.

Post time: Aug-22-2023