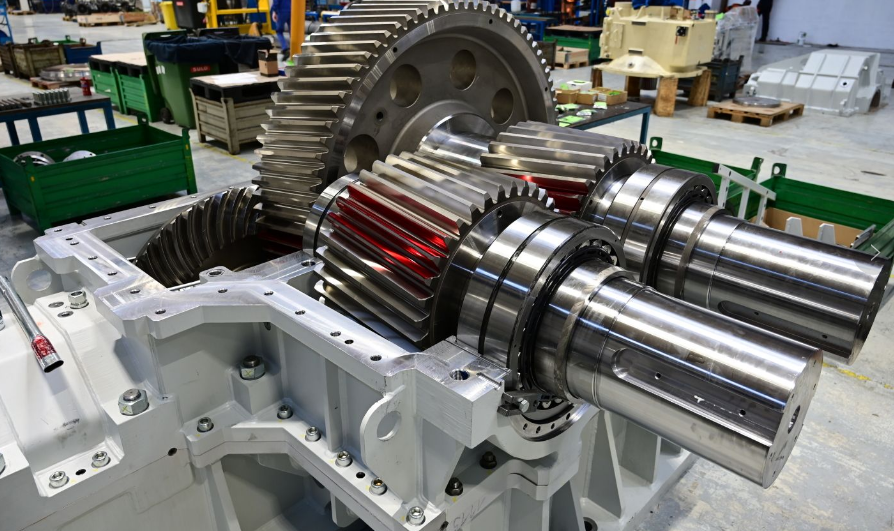

Bevel Gears with Output Shafts for Rubber Mixer Gearboxes: Enhancing Performance and Durability

Rubber mixers are essential in industries like tire manufacturing, industrial rubber production, and polymer processing. The gearbox is a critical component in these machines, responsible for transferring power efficiently and reliably to ensure consistent mixing performance. Among the various gear solutions,

bevel gears with output shafts have emerged as a superior choice for rubber mixer gearboxes.

Why Bevel Gears for Rubber Mixers?

Bevel gears are designed to transmit power between shafts at intersecting angles, often at 90 degrees. This makes them particularly well-suited for the complex torque requirements of rubber mixers. The inclusion of an output shaft simplifies the integration of the gearbox with the mixing mechanism, providing several operational benefits.

Key Advantages

- Efficient Torque Transmission: bevel gears deliver high torque levels efficiently, ensuring the rubber mixer can handle heavy loads and demanding mixing tasks.

- Compact Design: By combining the bevel gear and output shaft, these gearboxes save space while maintaining performance, an essential feature for compact machinery designs.

- Durability: Made from high strength materials and engineered for precision, bevel gears withstand the high stresses and wear typical in rubber mixing applications.

- Smooth Operation: The precise design minimizes vibration and noise, creating a stable and quieter working environment.

- Customization: Bevel gear systems can be tailored to specific rubber mixing requirements, such as speed ratios, torque capacities, and output configurations.

Applications in Rubber Mixers

Rubber mixers require robust and reliable gear systems to manage the shear forces involved in mixing rubber compounds. Bevel gearboxes with output shafts are ideal for:

- Internal Mixers: Supporting heavy duty mixing of rubber and other polymers.

- Open Mills: Driving the rollers for efficient material processing.

- Extruders: Ensuring consistent material flow for downstream applications.

Belon Gears Application

Improved Performance and Longevity

Integrating bevel gears with output shafts into rubber mixer gearboxes results in:

- Higher productivity due to reduced downtime and maintenance.

- Improved energy efficiency, lowering operational costs.

- Extended equipment lifespan, as the gears are designed for the rigors of industrial use.

Bevel gears with output shafts offer a reliable and efficient solution for rubber mixer gearboxes, meeting the high demands of modern rubber processing. Whether it’s achieving optimal torque, durability, or space efficiency, these gear systems ensure mixers perform at their peak.

Looking to upgrade your rubber mixer gearboxes? Let’s discuss how our bevel gear solutions can help you enhance your operations!

Post time: Dec-02-2024