How Are Double Helical Gears Used in Gearboxes?

Double helical gears are a crucial component in many high performance gearboxes, particularly in heavy duty industrial applications. They are designed to improve efficiency, reduce noise and vibrations, and handle higher loads compared to conventional spur or helical gears. This article explores how double helical gears are used in gearboxes and the advantages they offer

ears

ears

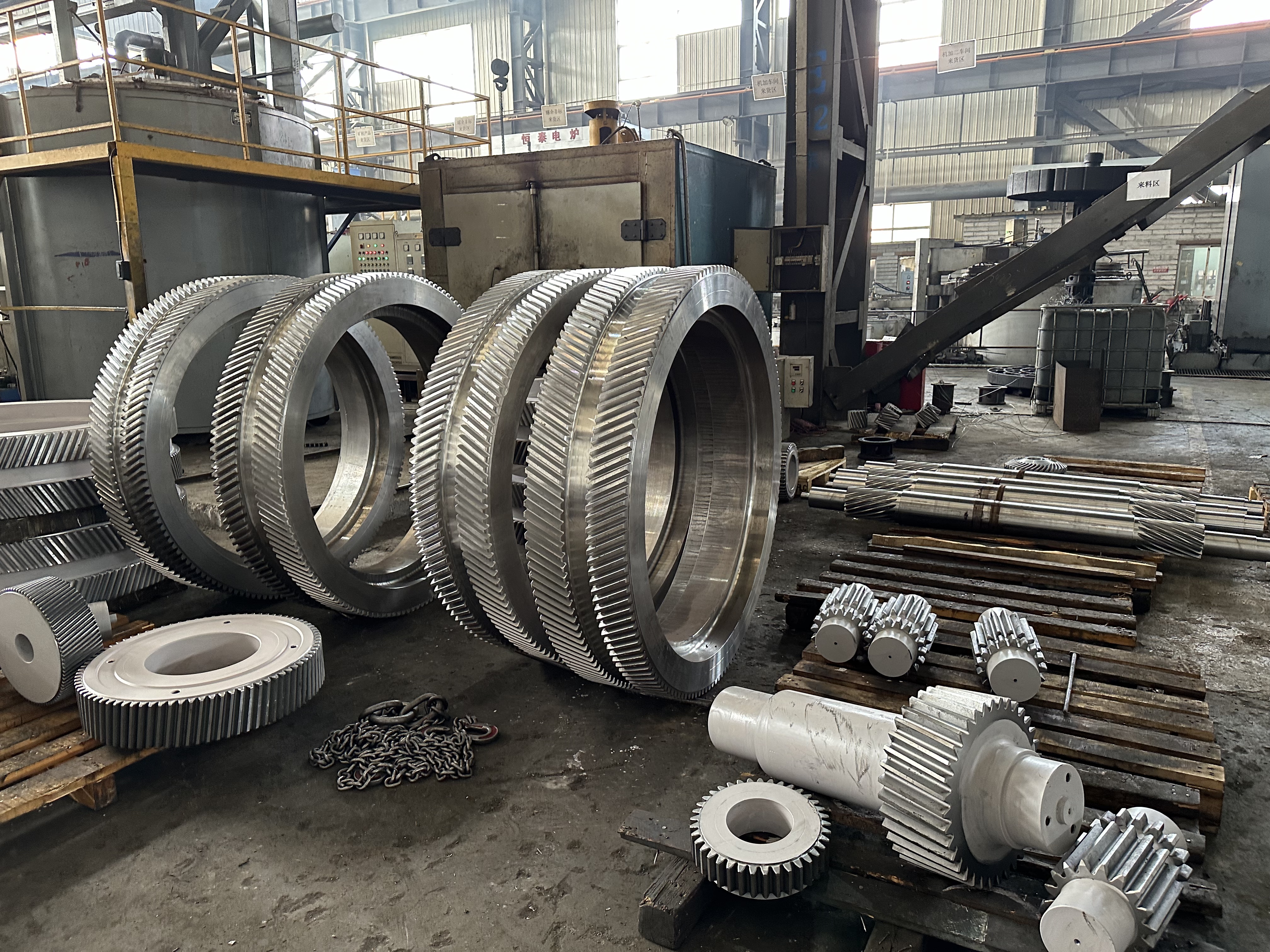

A double helical gear consists of two opposing helical gears placed side by side with a gap in between. This configuration effectively cancels out axial thrust, which is a common issue in single helical gears. The opposing helix angles help balance the forces, making the gear more stable and reducing wear on the bearings and housing.

Application in Gearboxes

Gearboxes equipped with double helical gears are commonly used in industries requiring high torque transmission with minimal losses. Some common applications include:

1.Power Generation – Double helical gears are widely used in turbine-driven gearboxes for power plants, ensuring smooth and efficient power transmission.

2.Marine Propulsion Systems – Large ships and naval vessels use double helical gears in their main propulsion systems to achieve high efficiency and durability.

3.Heavy Machinery – Mining equipment, cement mills, and steel mills employ double helical gearboxes to handle heavy loads with minimal maintenance.

4.Oil and Gas Industry – Compressors and pumps in refineries often rely on double helical gearboxes for stable and continuous operation under extreme conditions.

Advantages of Double Helical Gears in Gearboxes

The use of double helical gears in gearboxes offers several advantages:

- Reduced Axial Load: Since the opposing helix angles cancel out axial thrust, the need for thrust bearings is minimized, increasing the lifespan of the gearbox.

- Higher Load Capacity: The wider contact area of double helical gears allows them to transmit higher torque without excessive wear.

- Smooth and Quiet Operation: The continuous engagement of teeth ensures smoother power transmission and significantly reduces noise and vibrations.

- Increased Efficiency: Due to lower friction losses and better load distribution, double helical gears improve the overall efficiency of the gearbox.

- Greater Durability: These gears experience less stress and wear, making them ideal for heavy-duty and long-term industrial applications.

Double helical gears play a vital role in the design of efficient and high-performance gearboxes. Their ability to handle high loads while reducing axial thrust and noise makes them the preferred choice for various industrial applications. As industries continue to demand higher efficiency and durability, the use of double helical gears in gearboxes is expected to grow, further improving machinery performance and reliability

Post time: Feb-26-2025