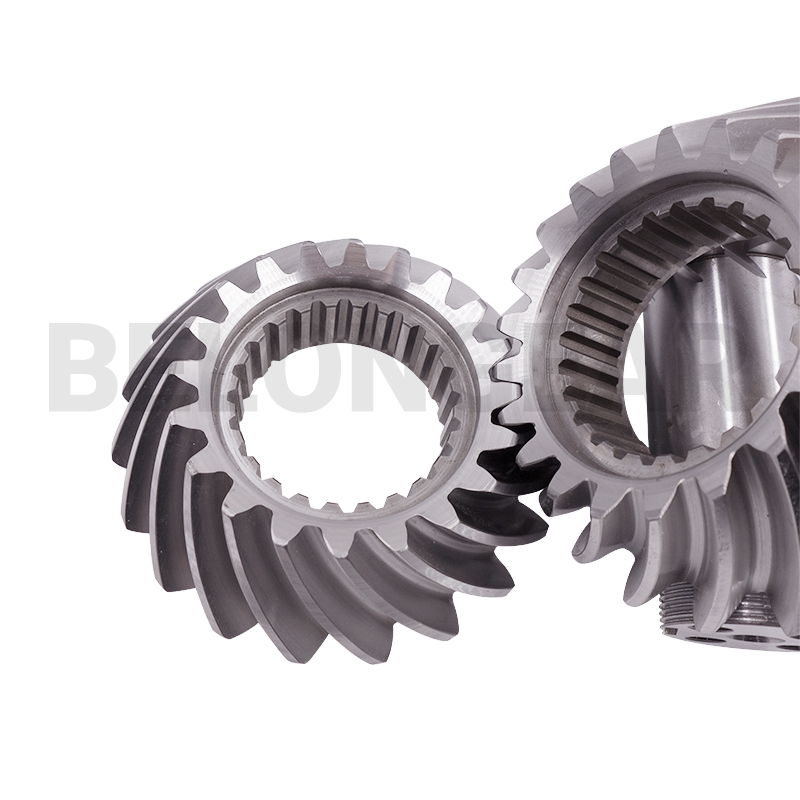

Miter gears assume a vital role in machinery as they serve as essential components for transmitting power between shafts that intersect at a right angle. The design of these gears allows for a right angle change in the direction of rotation, making them suitable for various applications. Here’s an exploration of their role in machinery, with a focus on conveying power between perpendicular shafts:

1. Power Transmission

One of the primary roles of miter gears in machinery is power transmission. They are used to transmit rotational power efficiently between shafts that are oriented at a 90-degree angle to each other. This is particularly useful in situations where space constraints or design requirements dictate a change in the direction of power flow.

2. Shaft Misalignment Compensation:

Machinery components are not always perfectly aligned, and miter gears are effective in compensating for slight misalignments between perpendicular shafts. The gear teeth of miter gears engage smoothly, allowing for the transfer of power even when the shafts are not perfectly aligned.

3. Versatility in Applications:

Miter gears find applications in a wide range of machinery types, including but not limited to conveyor systems, milling machines, and printing presses. Their versatility makes them suitable for diverse industrial settings where the efficient transmission of power at right angles is required.

4. Compact Design:

The compact and space-efficient design of miter gears makes them ideal for machinery where space is a critical consideration. Their ability to change the direction of power transmission in a confined space is essential for the compact design of various mechanical systems.

5. Precision and Accuracy:

Miter gears are often used in machinery that demands precision and accuracy. Their meshing teeth provide a stable and reliable means of power transmission, ensuring that the rotational motion is transferred with minimal backlash and play.

6. Gear Reduction and Speed Control:

In machinery requiring gear reduction or speed control, miter gears can be part of a system that adjusts the speed and torque of the output shaft relative to the input shaft. This is particularly useful in applications where different operational speeds are necessary.

7. Industrial and Manufacturing Equipment:

Miter gears are commonly employed in various industrial and manufacturing equipment, such as assembly lines, packaging machines, and textile machinery. Their role in these applications involves changing the direction of power flow efficiently and reliably.

In summary, miter gears play a crucial role in machinery by enabling the efficient transmission of power between perpendicular shafts. Their versatility, compact design, and ability to compensate for misalignments make them valuable components in a wide range of industrial applications, contributing to the smooth and reliable operation of machinery in diverse settings.

Post time: Dec-05-2023