Gear is a power transmission element. Gears determine the torque, speed, and direction of rotation of all the machine components being driven. Broadly speaking, gear types can be divided into five main categories. They are cylindrical gear, bevel gear, helical gear, rack and worm gear. There are a lot of intricacies in different types of gears. In fact, the selection of gear type is not an easy process. It depends on many considerations. The factors that affect it are physical space and shaft arrangement, gear ratio, load, precision and quality level, etc.

Gear type

Gear types used in mechanical power transmission

According to the industrial application, many gears are manufactured with different materials and different performance specifications. These gears have a variety of capacities, sizes and speed ratios, but their main function is to convert the input of the prime mover into an output with high torque and low RPM. From agriculture to aerospace, from mining to paper making and pulp industry, these gear series can be used in almost all industries.

Cylindrical gears are spur gears with radial teeth, which are used to transmit power and motion between parallel shafts. These gears are widely used for speed increase or speed reduction, high torque and positioning system resolution. These gears can be mounted on hubs or shafts. Gears have different sizes, designs, shapes, and also provide various features and functions to meet different industrial requirements.

Materials used

Cylindrical gears are made of high-quality materials, such as:

Metals - steel, cast iron, brass, bronze and stainless steel.

Plastics - Acetal, nylon and polycarbonate.

The use of the materials used to make these gears should bear in mind certain factors, including design life, power transmission requirements, and noise generation.

Important specifications to be considered

Gear center

aperture

Shaft diameter

Use of cylindrical gears

These gears are widely used in many fields, including

automobile

textile

industrial engineering

Bevel gear is a mechanical device used to transmit mechanical power and motion. These gears are widely used to transmit power and motion between non parallel shafts and are designed to transmit motion between intersecting shafts, usually at right angles. The teeth on bevel gears can be straight, helical or hypoid. Bevel gears are suitable when it is necessary to change the direction of rotation of the shaft.

Materials used

The use of the materials used to make these gears should bear in mind certain factors, including design life, power transmission requirements, and noise generation. Some important materials used are:

Metals - steel, cast iron and stainless steel.

Plastics – Acetal and polycarbonate.

Important specifications to be considered

Gear center

aperture

Shaft diameter

Use of bevel gears

These gears are widely used in many fields, including:

Automobile industry

textile industry

Industrial engineering products

Helical gear is a kind of popular gear. Its teeth are cut at a certain angle, so it can make the meshing between gears more smooth and smooth. Helical gear is an improvement on cylindrical gear. The teeth on helical gears are specially chamfered to face the gears. When the two teeth on the gear system mesh, it starts to contact at one end of the teeth, and gradually expands with the rotation of the gear until the two teeth are fully engaged. Gears have different sizes, shapes and designs to meet customer specifications.

Materials used

These gears can be made of high-quality materials, including stainless steel, steel, cast iron, brass, etc., depending on the application.

Use of helical gears

These gears are used in areas where high speed, high power transmission or noise prevention are important.

automobile

textile

space flight

Conveyor

Rack

Gear rack

The rack is usually used to convert rotary motion into linear motion. It is a flat bar on which the teeth of the pinion mesh. It is a gear whose shaft is at infinity. These gears are designed for a variety of applications.

Materials used

Considering the application, a variety of materials are used. Some commonly used materials are:

Plastic

brass

steel

cast iron

These gears ensure quieter and smoother operation. The mechanism provides less backlash and better steering feel.

Use of rack

Gears are often used in the steering mechanism of automobiles. Other important applications of the rack include:

Building equipment

Mechanical tools

Conveyor

Material handling

Roller feed

Worm gear

A worm gear is a gear that engages with the worm to significantly reduce speed or allow higher torque to be transmitted. The gear can achieve a higher transmission ratio than cylindrical gears of the same size.

Materials used

Worm gears can be made of a variety of materials, depending on the final application. Some commonly used materials are:

brass

stainless steel

cast iron

aluminium

chilled steel

Worm gear can operate under difficult conditions and has the ability to achieve large deceleration. Worm gears can also transmit high loads at high speed ratios.

Type of worm gear

Laryngeal

Single throat

Diphtheria

Use of worm gear

These gears are suitable for:

Motor

Auto parts

Sprocket

Sprockets are gears with metal teeth that mesh with the chain. Also called cogwheel, it is a small gear ring that can be installed on the rear wheel. It is a thin wheel whose teeth mesh with the chain.

Materials used

A variety of materials can be used to manufacture high-quality chain wheels for different industries. Some of the materials used are:

stainless steel

chilled steel

cast iron

brass

Use of chain wheel

This simple gear can be used in different fields, including:

food industry

Bicycle

motorcycle

automobile

Tank

Industrial machinery

Movie projectors and cameras

Sector gear

Sector gear

The sector gear is basically a set of gears. These gears consist of a large number of parts, which are small parts of a circle. The sector gear is connected with the arm or tug of the water wheel. The sector gear has a component that receives or conveys reciprocating motion from the gear. These gears also include a sector shaped ring or gear. There are also gears around. The sector gear has various surface treatments, such as no treatment or heat treatment, and can be designed as a single component or the entire gear system.

application

Sector gears are used for various industrial applications. These gears have many advantages, such as higher flexibility, excellent surface finish, high accuracy and minimal wear. Some uses of sector gears include:

defense

rubber

Railway

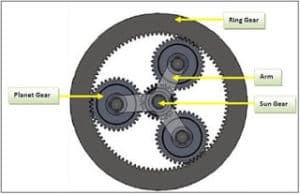

Planet gear

planet gear

Planetary gears are external gears that rotate around a central gear. Planetary gears can produce different gear ratios, depending on which gear is used as input and which gear is used as output.

Materials used

Gears can be made of a variety of materials, including:

stainless steel

chilled steel

cast iron

aluminium

These gears are suitable for decelerating high speed motors for high torque low speed applications. These gears are used for precision instruments because of their reliability and accuracy.

Use of planetary gears

These gears are the most widely used and have many applications, including:

Sugar industry

Power industry

Wind power generator

Marine industry

Agricultural industry

Internal gear

Internal gear

The internal gear is a hollow gear with teeth on its internal surface. The teeth in this gear protrude inward from the rim rather than outward.

Materials used

Depending on the final application, there are a number of materials that can be used to make internal gears. Some commonly used materials are:

Plastic

aluminium alloy

cast iron

stainless steel

The teeth in such gears can be straight or helical. The internal gear is concave, and the tooth bottom is thicker than the external gear. The convex shape and solid base help to make the teeth stronger and reduce noise.

Advantages of internal gears

Gears are specially designed to suit various equipment.

These gears are cost-effective and ideal for a variety of lightweight applications.

The design without binding teeth ensures smooth and quiet operation.

Use of internal gears

Light applications

Roller

Indexes

External gear

External gear

As one of the simplest and most commonly used gear units, external gears are widely used in gear pumps and other industrial products to ensure smooth operation. These gears have straight teeth parallel to the axis. Teeth transmit rotational motion between parallel axes.

Materials used

Gears can be made of a variety of materials, including:

stainless steel

chilled steel

cast iron

aluminium

The kind of materials used to make these gears depends on their end use.

Use of external gears

These gears are used in different fields, including:

Coal industry

mining

Iron and Steel Plant

Paper and pulp industry

Post time: Dec-02-2022