Tobacco processing involves multiple stages, including leaf handling cutting drying, flavoring, and packaging. To ensure smooth, precise, and efficient operations, various types of gears are used in the machinery. These gears help drive conveyors, cutting blades, rollers, and other critical components. Below are some of the most commonly used gears in tobacco processing equipment.

1. Helical Gears

Helical gears are widely used in conveyors shredders and elevators due to their smooth and quiet operation. Their inclined tooth design ensures continuous contact between teeth, reducing noise and increasing efficiency. Helical gears can handle high speeds and loads, making them ideal for high-performance tobacco processing machines.

2. Bevel Gears (Straight & Spiral)

Bevel gears are crucial in machinery where the transmission direction needs to change, such as in cutting machines and distribution systems. Straight bevel gears are simpler and cost-effective, while spiral bevel gears provide smoother and quieter operation, making them suitable for high-speed applications. Their durability ensures precision in tobacco cutting and movement systems.

3. Planetary Gears

Planetary gear systems are used in feeding systems, flavoring equipment, and motor reducers. Their compact design allows for a high gear reduction ratio while maintaining efficiency. Since planetary gears distribute the load across multiple gears, they provide increased torque capacity and smoother power transmission, essential for automated tobacco processing machines.

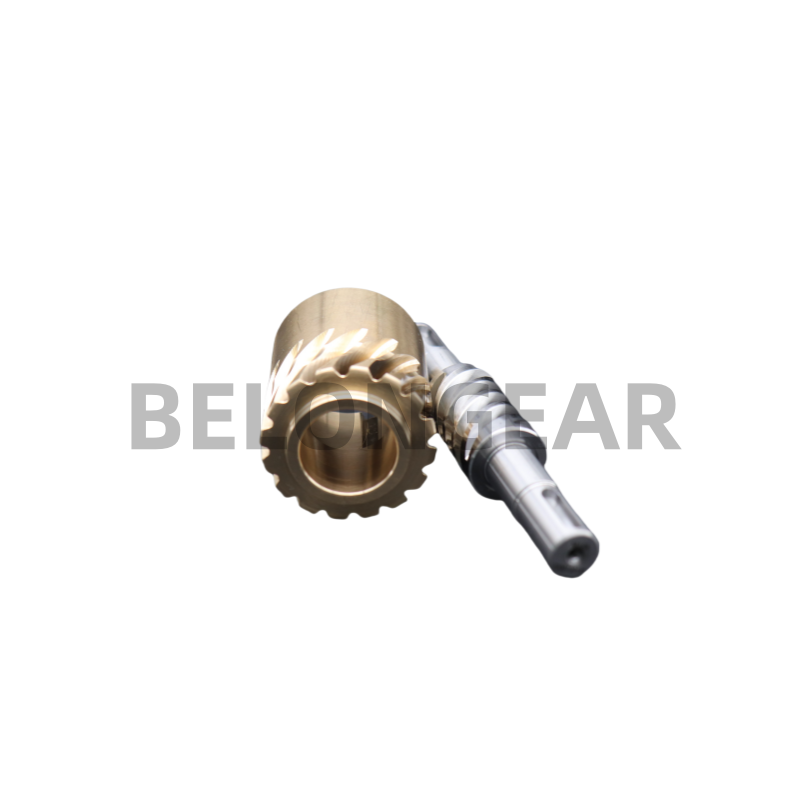

4. Worm Gears

Worm gears are preferred for applications that require high reduction ratios and self-locking capabilities, such as in tobacco conveyor systems and positioning mechanisms. These gears provide high torque output with minimal space requirements. Additionally, their self locking feature prevents back-driving, ensuring safety and precision in processing lines.

5. Rack and Pinion Gears

Rack and pinion systems are used in pusher mechanisms and cutting adjustment systems. These gears convert rotational motion into linear movement, enabling precise positioning of components like cutting blades and feeding mechanisms. Their high accuracy and durability make them essential in tobacco machinery that requires controlled movements.

The Importance of High Quality Gears

In the tobacco industry, precision and durability are critical. Poor-quality gears can lead to machine downtime, inconsistent product quality, and increased maintenance costs. Choosing high-precision, wear-resistant, and properly lubricated gears ensures optimal performance, longevity, and efficiency.

At Belon Gears, we specialize in manufacturing customized bevel gears, helical gears, and high-precision gear solutions for industrial applications, including tobacco processing machinery. Our advanced lapping, broaching, and quality control processes ensure that every gear meets the highest standards.

For more information on how Belon Gears can enhance your machinery’s performance, feel free to reach out!

#TobaccoProcessing #GearManufacturing #BelonGears #BevelGears #HelicalGears #PrecisionEngineering

Post time: Mar-21-2025