Ground bevel gears are a type of gear that has been precision-machined to ensure a high quality mesh with

minimal backlash and noise. They are used in applications where high precision and low noise operation are

required. Here are some key points about ground bevel gears and their applications:

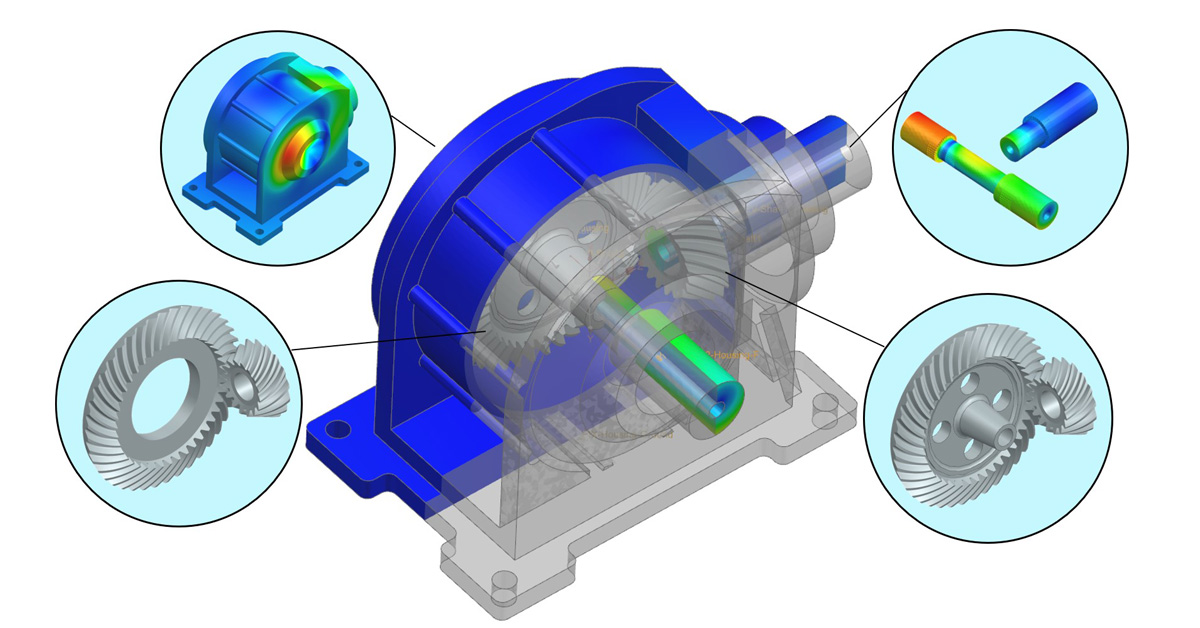

1. **Precision Machining**: Ground bevel gears are manufactured using a grinding process that ensures the teeth

are precisely shaped and sized. This process removes any imperfections and provides a smooth surface finish.

2. **High Accuracy**: The grinding process results in gears with high accuracy, which is essential for maintaining

a consistent transmission ratio and reducing wear.

3. **Low Backlash**: Ground bevel gears have minimal backlash, which is the amount of space between the

mating teeth. This reduces noise and vibration and improves the overall efficiency of the transmission system.

4. **Low Noise Operation**: Due to the precision machining and minimal backlash, these gears operate with low

noise,making them suitable for applications where noise is a concern.

5. **Long Life**: The smooth surface finish and precision machining contribute to longer gear life, as there is less

wear and tear on the teeth.

6. **Applications**:

- **Automotive**: Used in transmission systems where precision and quiet operation are critical.

- **Aerospace**: Employed in control systems where reliability and precision are paramount.

- **Machine Tools**: Utilized in high-precision machine tools where the accuracy of gear mesh is crucial.

- **Robotics**: Ground bevel gears can be found in robotic arms and joints where smooth and precise movement

is necessary.

- **Medical Equipment**: Used in devices that require precise motion control and quiet operation, such as

surgical instruments.

7. **Maintenance**: Ground bevel gears require less maintenance due to their durability and precision, which

can lead to cost savings over time.

8. **Customization**: These gears can be customized to meet specific application requirements, including size,

tooth profile, and material.

9. **Material Options**: Ground bevel gears can be made from a variety of materials, including steel, brass, and

other alloys, depending on the application’s needs for strength, durability, and resistance to wear.

10. **Environmental Considerations**: The precision of ground bevel gears can contribute to energy efficiency

and reduced environmental impact by minimizing energy loss in the transmission system.

Ground bevel gears are an excellent choice for applications that demand high precision, quiet operation, and

long-termreliability. Their use can significantly enhance the performance and lifespan of machinery and

equipment in various industries.

Post time: Jun-04-2024