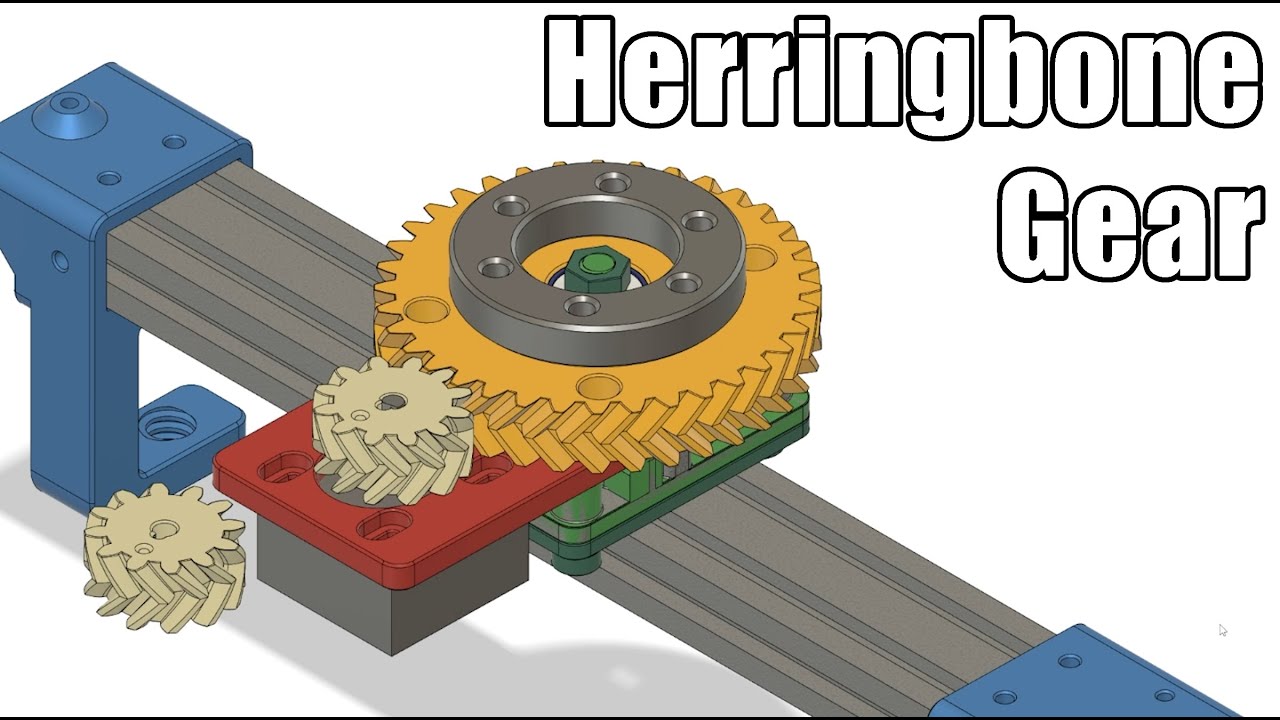

Herringbone gears, also known as double helical gears, are specialized gears with a unique tooth arrangement that

offers several advantages over other types of gears. Here are some specific applications where herringbone gears are

commonly used:

Power Transmission in Heavy Machinery:

Herringbone gears are widely used in heavy machinery and equipment where high torque transmission is required.

Their double helical design helps to counteract the axial forces that can occur in single helical gears, making them ideal

for applications such as industrial gearboxes, mining equipment, and steel rolling mills.

Reduction of Vibration and Noise:

The dual helical structure of herringbone gears significantly reduces vibrations and noise compared to single helical

gears. This makes them suitable for applications where quiet operation is crucial, such as in precision machinery,

printing presses, and textile machinery.

Aerospace and Defense:

Herringbone gears are used in aerospace applications, including aircraft engines and helicopter transmissions. Their

ability to handle high loads and provide smooth operation makes them valuable in critical aerospace systems where

reliability and efficiency are paramount.

Power Generation:

In power generation equipment such as turbines and generators, herringbone gears are utilized to transfer rotational

energy efficiently and reliably. Their robust design ensures stable operation even under high loads and varying

operating conditions.

Oil and Gas Industry:

Herringbone gears are employed in pumps, compressors, and other equipment in the oil and gas industry. They can

withstand harsh environmental conditions and provide consistent performance over extended periods, making them

suitable for critical applications in this sector.

Marine Applications:

Herringbone gears are used in marine propulsion systems and ship machinery where they help transmit power

efficiently while minimizing noise and vibration. Their reliability and durability make them well-suited for the demanding

conditions of marine environments.

Automotive Industry:

While less common compared to other industries, herringbone gears find application in specialized automotive systems

such as racing transmissions and heavy-duty trucks where robust power transmission and reduced noise are beneficial.

Overall, herringbone gears are valued for their ability to handle high torque, reduce noise and vibration, and provide

reliable power transmission in a wide range of industrial and specialized applications. Their unique tooth arrangement

and design characteristics make them particularly suitable for demanding environments where efficiency and reliability

are critical.

Post time: Jul-21-2024