Gear ratios play a crucial role in the functioning of various mechanical systems, from bicycles to automobiles and industrial machinery. Understanding how gear ratios work is fundamental to appreciating the mechanics behind efficient power transfer.

What are Gear Ratios?

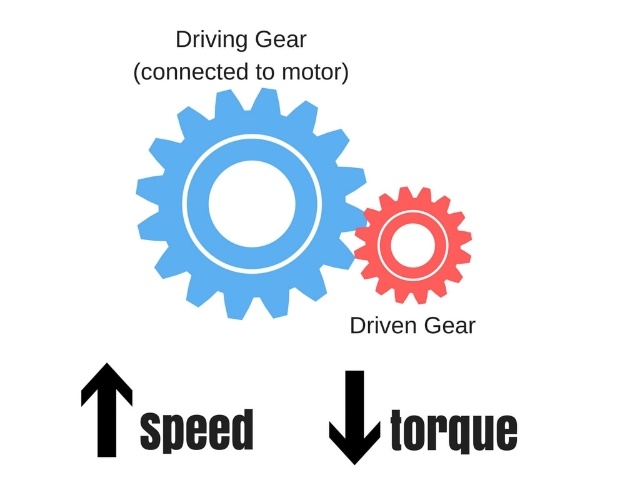

Gear ratios are a way to describe the relationship between the rotational speeds of two or more intermeshing gears. They determine the speed and torque at which power is transmitted between rotating components. Essentially, gear ratios define how many times the driving gear must turn in order to make the driven gear complete a full revolution.

Calculating Gear Ratios:

Gear ratios are calculated by comparing the number of teeth on each gear. The gear with more teeth is called the driving gear or the input gear, while the one with fewer teeth is known as the driven gear or the output gear. The ratio is determined by dividing the number of teeth on the driving gear by the number of teeth on the driven gear.

read more types of gears Belon gear

The Application of Gears Across Various Industries

The versatility and efficiency of planetary gears have made them indispensable in various critical industries:

Power Tools gears : Planetary gear systems are fundamental to power tool gearboxes, offering a range of gear ratios and efficient power transmission in a compact design.

Aerospace gears : With their high power-to-weight ratio, planetary gears meet the aerospace industry's demanding standards for lightweight and high-performance components.

Robotics gears : The compact design of planetary gears is perfect for robotics, minimizing the need for extended gear trains while achieving significant reductions.

3D Printed Gears: While a variety of gears can be 3D printed, at Accu, we have developed projects utilizing 3D printed planetary gears to effectively distribute coffee grounds.

For example, if the driving gear has 30 teeth and the driven gear has 10 teeth, the gear ratio would be 75:25, or simply 3:1. This means that for every three revolutions of the driving gear, the driven gear completes one revolution.

Gear Ratio and Speed:

Gear ratios not only affect torque but also influence rotational speed. In a system with multiple gears, each gear has its own gear ratio, and the combined effect determines the overall gear ratio of the system.

When the driving gear has a larger number of teeth than the driven gear, it results in a higher gear ratio. A higher gear ratio means that the driven gear will rotate at a slower speed than the driving gear but with increased torque. This is useful for applications where more force is required, such as climbing steep hills or towing heavy loads.

On the other hand, if the driven gear has more teeth than the driving gear, it creates a lower gear ratio. In this case, the driven gear rotates faster than the driving gear, but with reduced torque. Lower gear ratios are suitable for applications that demand higher speeds, like reaching high velocities on a straight road.

Gear ratios are the mechanical wizards behind efficient power transfer in countless applications. We can adjust rotational speeds and torque to suit specific needs by manipulating the number of teeth on gears.

Post time: Jun-28-2023