A planetary gear set works by utilizing three main components: a sun gear, planet gears, and a ring gear (also known as an annulus). Here’s a

step-by-step explanation of how a planetary gear set operates:

Sun Gear: The sun gear is typically located at the center of the planetary gear set. It is either fixed or driven by an input shaft, providing theinitial

input rotation or torque to the system.

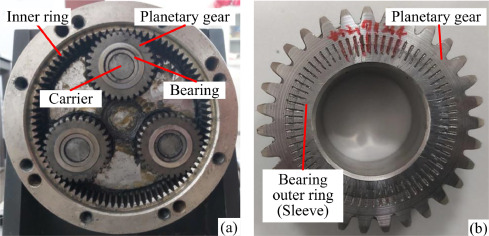

Planet Gears: These gears are mounted on a planet carrier, which is a structure that allows the planet gears to rotate around the sun gear. The

planet gears are evenly spaced around the sun gear and mesh with both the sun gear and the ring gear.

Ring Gear (Annulus): The ring gear is an outer gear with teeth on the inner circumference. These teeth mesh with the planet gears. The ring gear

can either be fixed to provide an output or be allowed to rotate to change the gear ratio.

Operation Modes:

Direct Drive (Stationary Ring Gear): In this mode, the ring gear is fixed (held stationary). The sun gear drives the planet gears, whichin turn

rotate the planet carrier. The output is taken from the planet carrier. This mode provides a direct (1:1) gear ratio.

Gear Reduction (Fixed Sun Gear): Here, the sun gear is fixed (held stationary). Power is input through the ring gear, causing it to drive the

planet gears. The planet carrier rotates at a reduced speed compared to the ring gear. This mode provides a gear reduction.

Overdrive (Fixed Planet Carrier): In this mode, the planet carrier is fixed (held stationary). Power is input through the sun gear, driving the

planet gears, which then drive the ring gear. The output is taken from the ring gear. This mode provides an overdrive (output speed higher than

input speed).

Gear Ratio:

The gear ratio in a planetary gear set is determined by the number of teeth on the sun gear, planet gears, and ring gear, as well as how these gears

are interconnected (which component is fixed or driven).

Advantages:

Compact Size: Planetary gear sets offer high gear ratios in a compact space, making them efficient in terms of space utilization.

Smooth Operation: Due to multiple teeth engagement and load sharing among multiple planet gears, planetary gear sets operate smoothly with

reduced noise and vibration.

Versatility: By changing which component is fixed or driven, planetary gear sets can provide multiple gear ratios and configurations, making them

versatile for different applications.

Applications:

Planetary gear sets are commonly found in:

Automatic Transmissions: They provide multiple gear ratios efficiently.

Watch Mechanisms: They allow for precise timekeeping.

Robotic Systems: They enable efficient power transmission and torque control.

Industrial Machinery: They are used in various mechanisms requiring speed reduction or increase.

In summary, a planetary gear set operates by transmitting torque and rotation through multiple interacting gears (sun gear, planet gears, and ring

gear), offering versatility in speed and torque configurations depending on how the components are arranged and interconnected.

Post time: Jun-21-2024