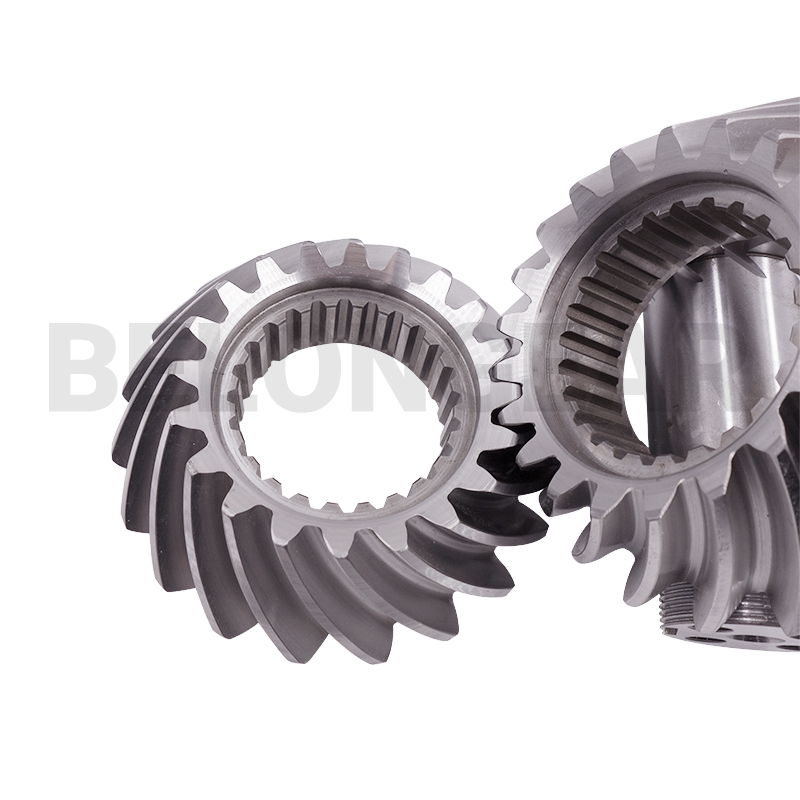

Miter gears play a crucial role in automotive applications, particularly in the differential system, where they contribute to the efficient transmission of power and enable the proper functioning of vehicles. Here’s a detailed discussion on how miter gears are used in the automotive industry:

1. Differential System:

Miter gears are an integral part of the differential system in vehicles. The differential is responsible for distributing torque to the wheels, allowing them to rotate at different speeds during turns. This is crucial for smooth handling and preventing tire wear.

2. Right Angle Power Transmission:

In the differential, miter gears are employed to change the direction of power transmission. They are specifically designed for right angle drives, allowing the rotational power from the engine to be redirected to the wheels at a 90 degree wheel

3. Torque Distribution:

Miter gears contribute to torque distribution between the two wheels, ensuring that each wheel receives the appropriate amount of power based on traction needs. This is essential for maintaining stability and control, especially during turns or uneven road conditions.

4. Limited-Slip and Locking Differentials:

Some automotive applications utilize limited-slip or locking differentials for enhanced traction and performance. Miter gears are utilized in these systems to enable controlled slippage or complete lockup of the differential, providing improved traction in challenging driving conditions.

5. Rear-Wheel and Four-Wheel Drive Systems:

Miter gears are commonly found in the differential assemblies of both rear-wheel drive and four-wheel drive vehicles. In these configurations, they facilitate the transfer of power from the transmission to the wheels while accommodating the varying rotational speeds of the wheels.

6. Efficiency and Durability:

Miter gears are preferred in automotive differentials for their efficiency in power transmission and durability under high torque conditions. Their design allows for a compact and robust solution, ensuring reliable performance over the lifespan of the vehicle.

In summary, miter gears in automotive applications, particularly in the differential system, contribute to the effective distribution and redirection of power, enhancing the overall performance, stability, and control of vehicles, especially in situations where varying wheel speeds and torque distribution are critical, such as during turns and challenging driving conditions.

Post time: Dec-05-2023